Gear shift simulation

Gear shift simulation

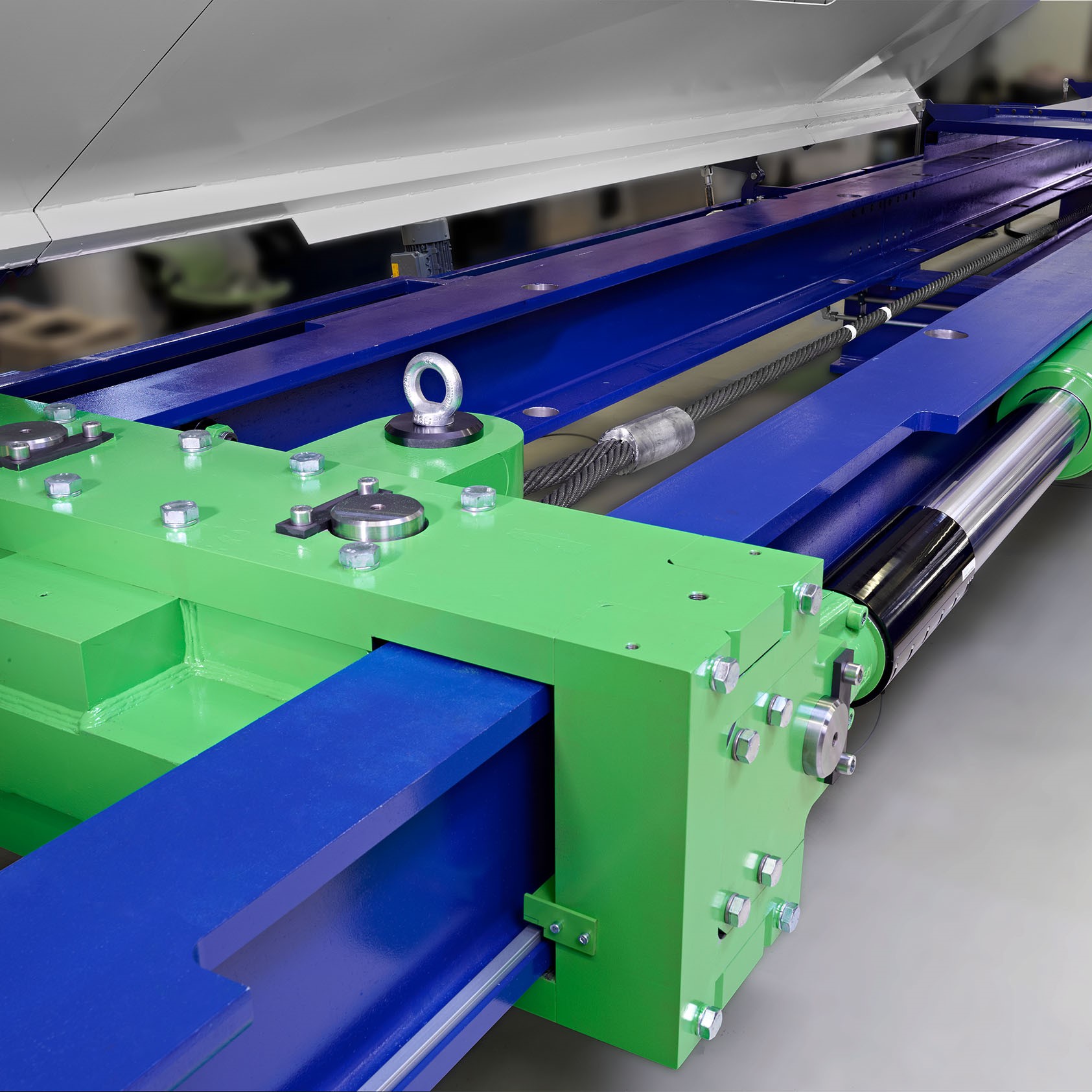

Three-axis test systems are used to test the service life of car gearshift levers.. By combining displacement and force control, shifting processes can be precisely simulated and repeated thousands of times. The use of a climate chamber rounds off the gearshift simulation under specified real-life conditions.

We are DYNA-MESS. Test Systems.

Description

Gear shift operations

The gear changes for 6-speed transmissions including reverse gear are performed in any order and can be repeated thousands of times. The individual gear changes are defined exactly by entering force and displacement values and are executed by the precisely controlled axes. Overpressing in the end positions and lateral force on the gear selector lever when engaging the gears are also taken into account.

Environmental simulation

The climate chamber is controlled via the software in synchronisation with the cyclical repetitions of the switching processes. The same switching operations can be carried out for a specified number of repetitions at specified temperatures. The climate chamber can be operated in the temperature range from -40°C to +140°C and humidity values of 10-98% at 10-90°C.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems