Horizontal testing machines

Horizontal testing machines

Horizontal testing machines from DYNA-MESS offer flexible testing options for various applications. They enable efficient testing and offer a versatile solution for different horizontal testing requirements in rope and lifting technology and other industries.

We are DYNA-MESS. Test Systems.

Technical properties

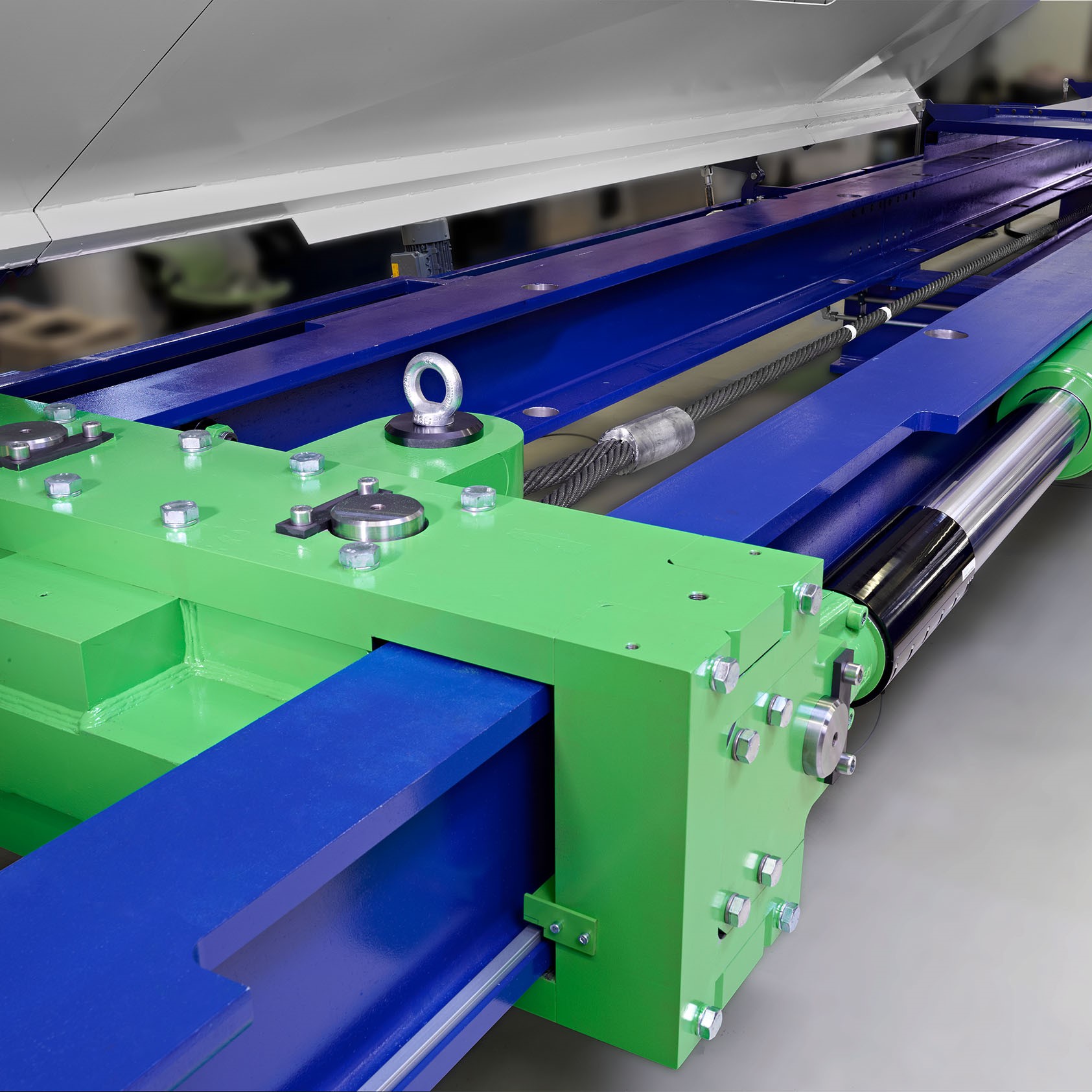

Test frame up to 12 MN test force and 40 m length

DYNA-MESS has built testing machines with lengths of up to 40 m and a dead weight of up to one hundred tonnes. Forces of up to 12 MN can be realised.

Standardised testing

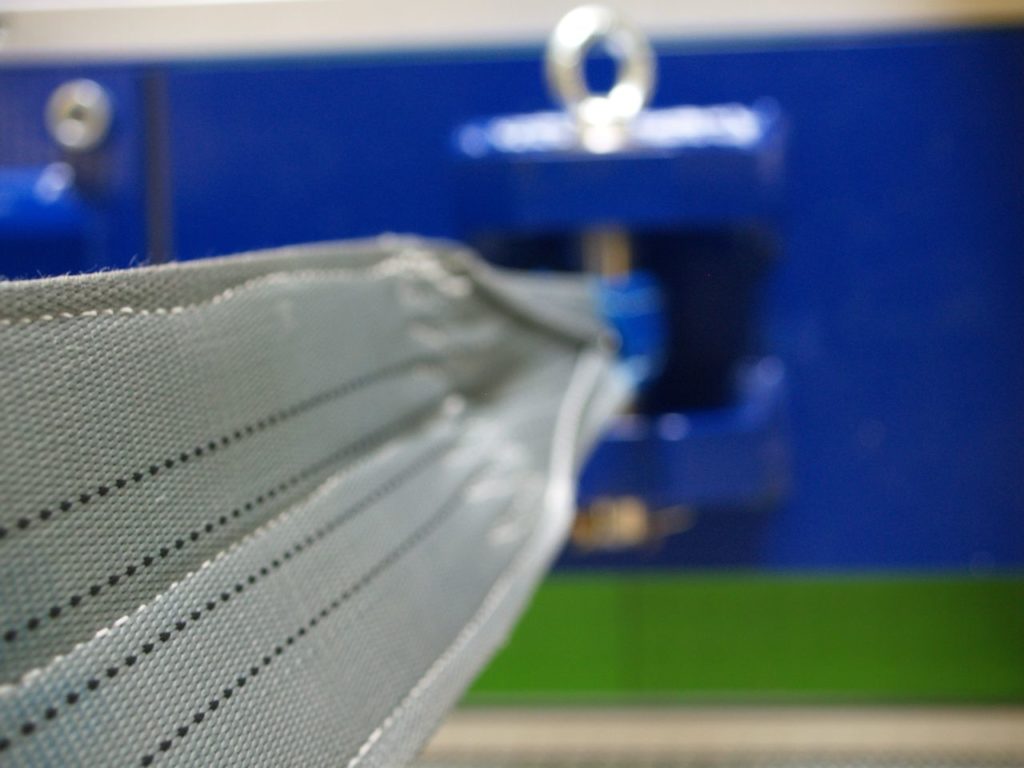

For standard-compliant testing of safety-relevant components, the tests can be displacement or force-controlled depending on the requirements. The digital machine control ensures that the test conditions (maximum load, test speeds, holding time, strain values, etc.) are precisely adhered to. The test is carried out automatically via special software modules that are created in accordance with a wide range of standards. Depending on the design, dynamic tests can also be carried out to determine the strain behaviour.

Special designs and stretching systems

Special requests for software design – from changes to existing software modules to the realisation of customers’ individual test specifications – are gladly accepted and implemented accordingly.

Customised solutions with, for example, large machine widths for torso testing (personal protective equipment) or large ice clamping lengths can also be easily implemented with the module frames. In some cases, the machines are also used as stretching machines for production in addition to the testing tasks.

The testing machine programme is rounded off by an extensive range of test specimen holders for ropes, belts, chains etc. as well as contact and non-contact strain measurement systems.

Mobile testing machines

Mobile testing machines offer efficient testing for chain slings, sling ropes, synthetic lifting slings and round slings. Optimised for mobile use in service vehicles, they enable maximum payload and simple operation via microcontrollers. The frame design is customisable and enables the integration of RFID transponders to identify the load handling attachments.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems