Machine elements

Our expertise in

machine elements

The testing of clutches and drive elements, springs, bearings and bushings as well as belts, bands and chains with DYNA-MESS testing systems ensures the high quality and reliability of these components through comprehensive mechanical tests. State-of-the-art testing systems guarantee precise analyses and support the development of durable and efficient products.

Couplings and

drive elements

DYNA-MESS offers testing machines for torsion tests on torsionally flexible and torsionally rigid couplings, on engageable and non-engageable couplings as well as for tests on disconnection and engagement points.

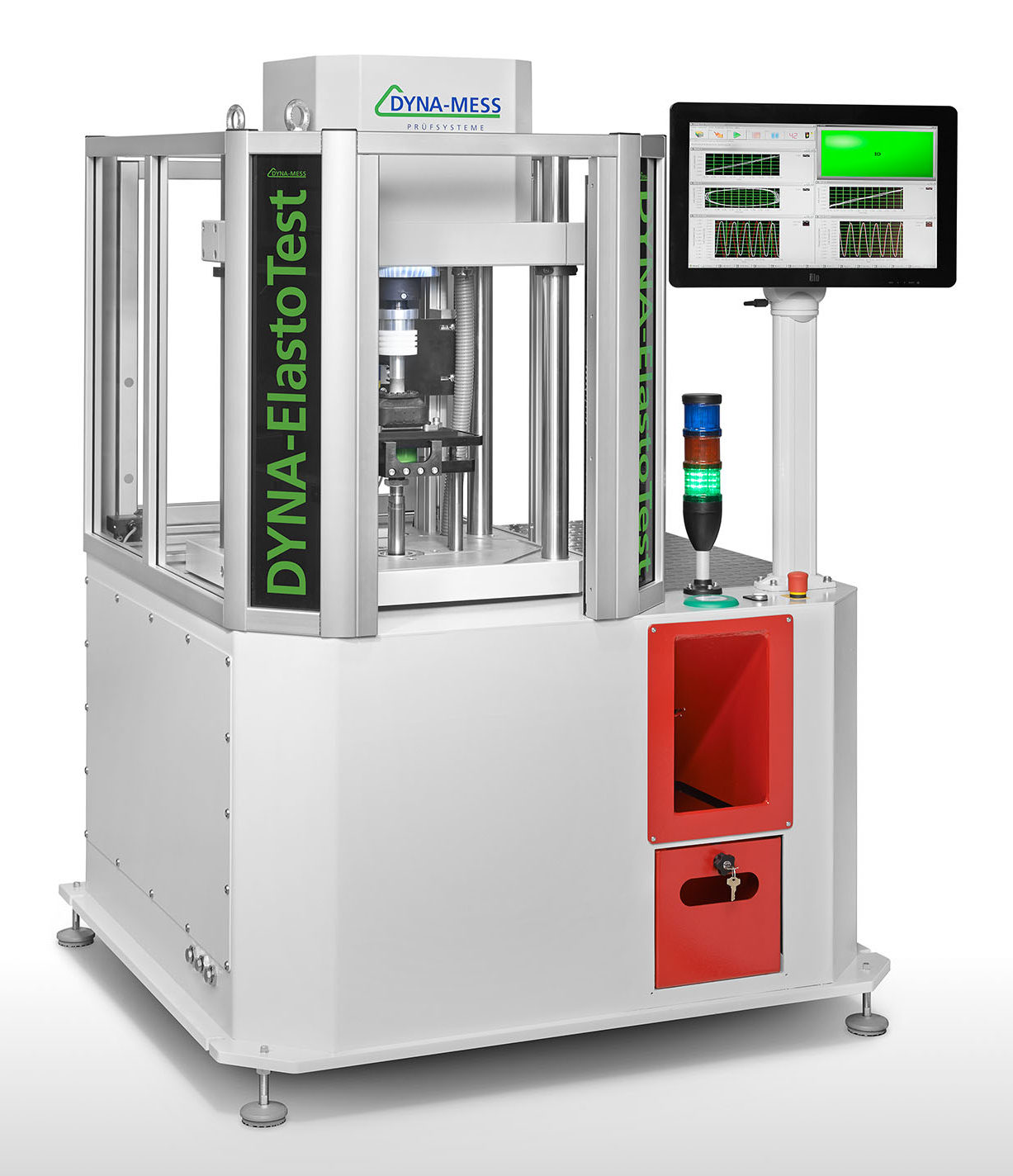

Springs

Regardless of whether you are testing the characteristic curve of arc springs, disc springs, tension or compression springs or require a test procedure specially tailored to your product. We at DYNA-MESS offer both standard solutions and highly specialised testing systems with “clamping force”.

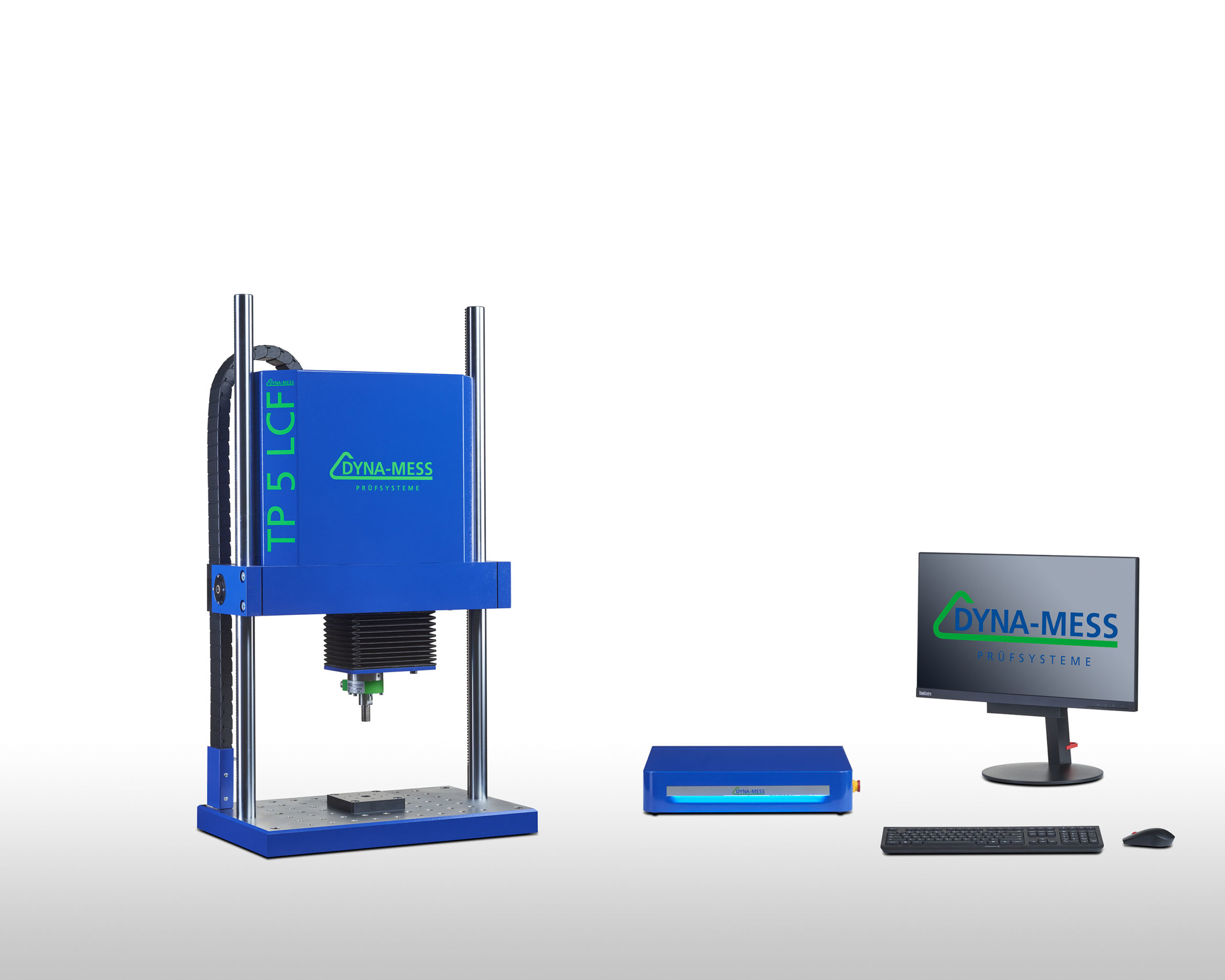

Bearings and bushes

Leading manufacturers rely on testing machines from DYNA-MESS for the development and quality control of modern rolling and plain bearings.

Straps, bands and chains

DYNA-MESS testing systems – the solution for testing your modern drive elements. Both standard testing machines for quality assurance of the raw material and customised test benches for e.g. service life tests, special event tests or remaining service life tests. With an optionally available climatic chamber, your products can be tested under operating conditions

SUITABLE PRODUCTS

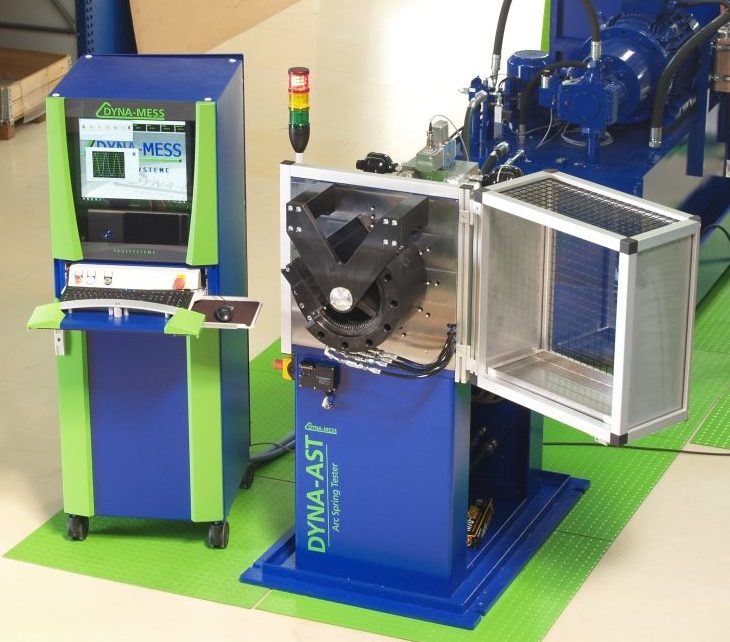

DYNA-AST

DYNA-MESS has developed the DYNA-AST (Arc Spring Tester) testing machine for the simultaneous testing of several arc springs.

End-of-line test systems

Production-integrated testing systems for automated 100% testing and iO/niO evaluation of components in the production process.

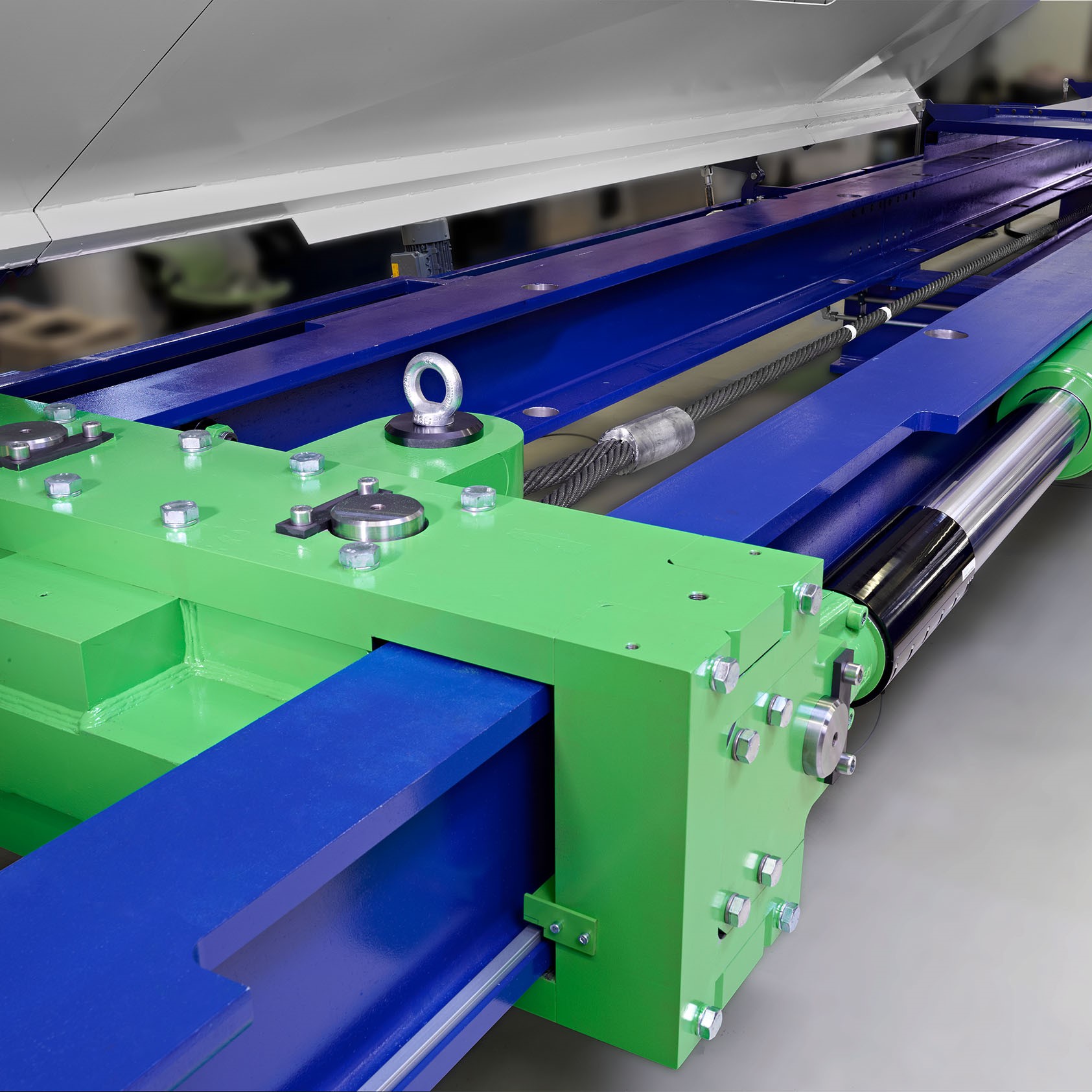

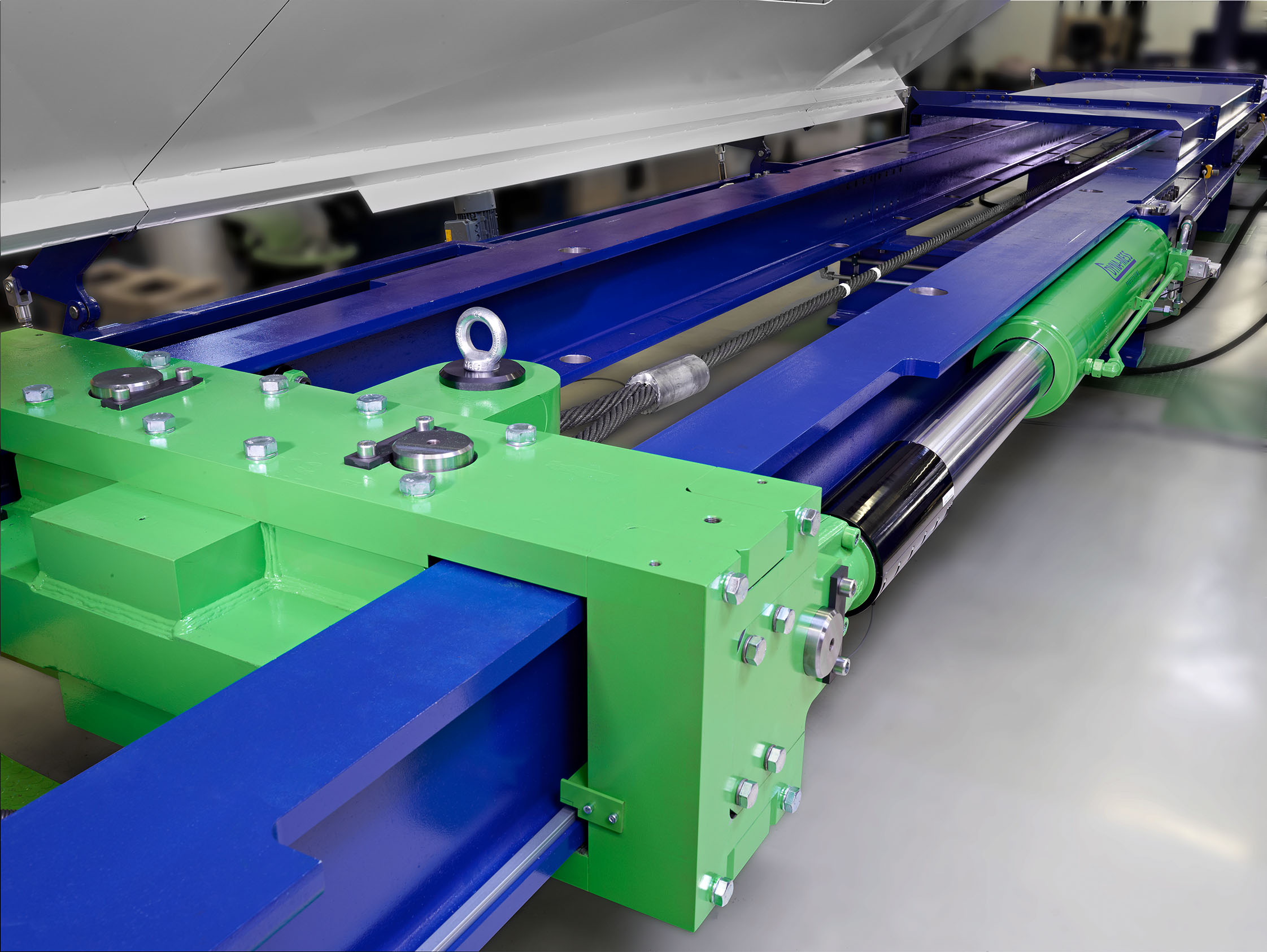

Horizontal testing machines

Horizontal testing machines from DYNA-MESS offer flexible testing options for various applications.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems