DYNA-EndoWear

DYNA-EndoWear:

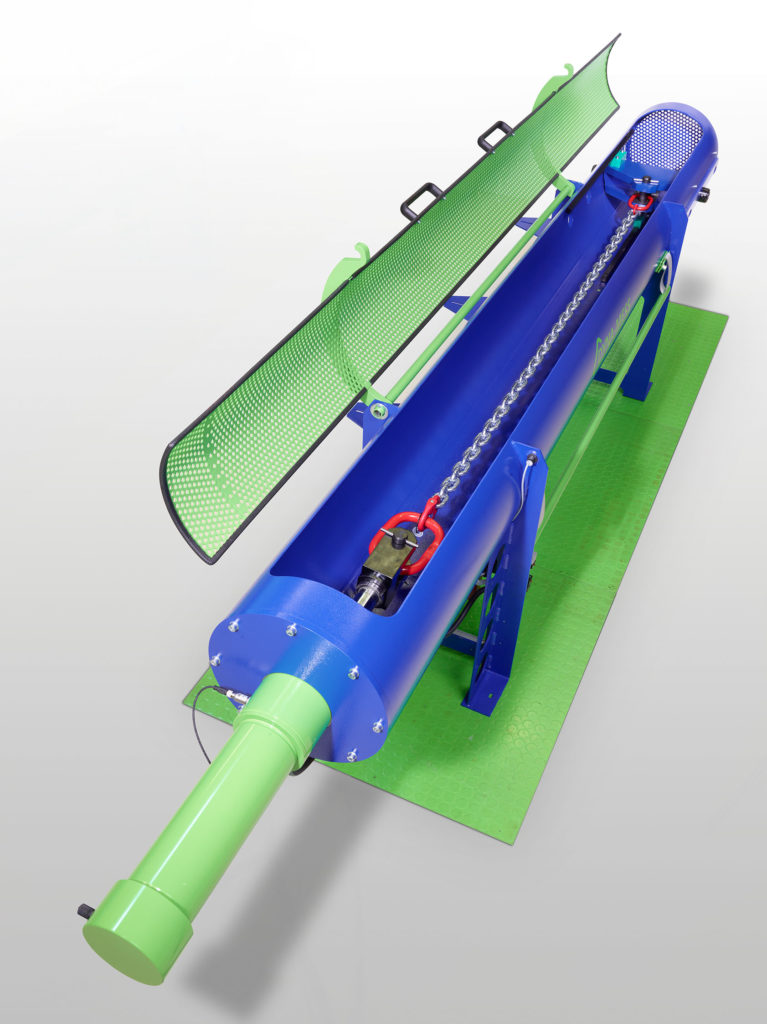

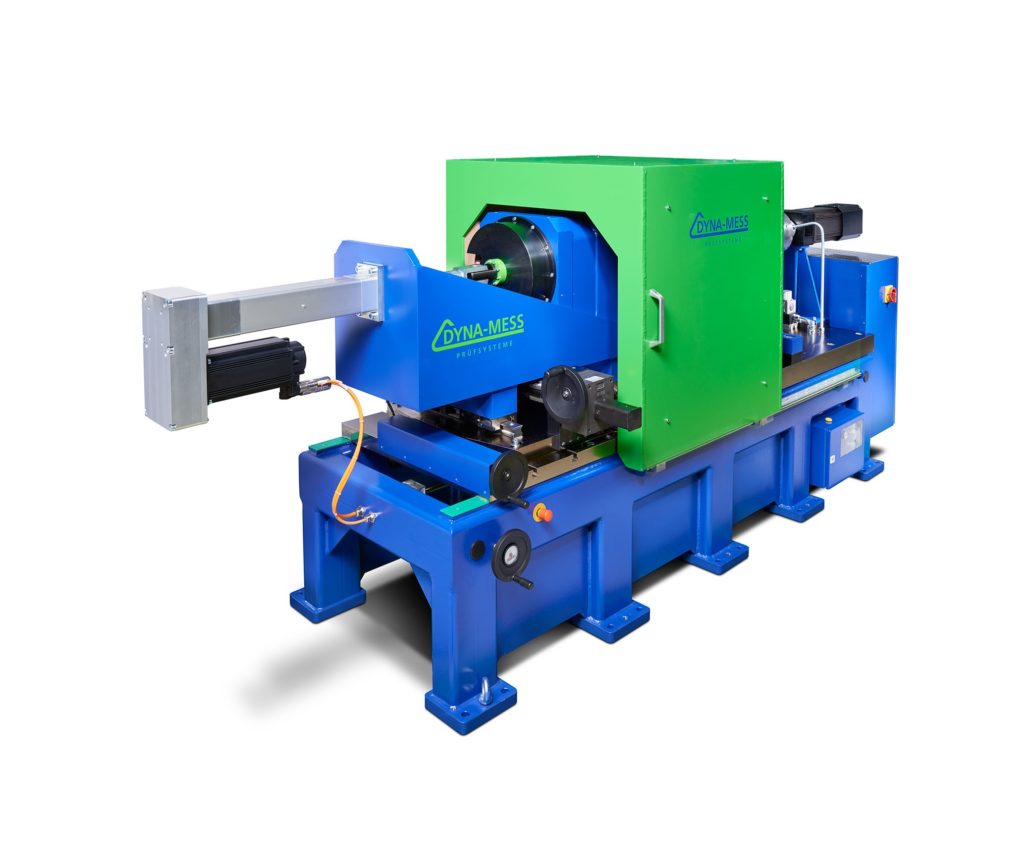

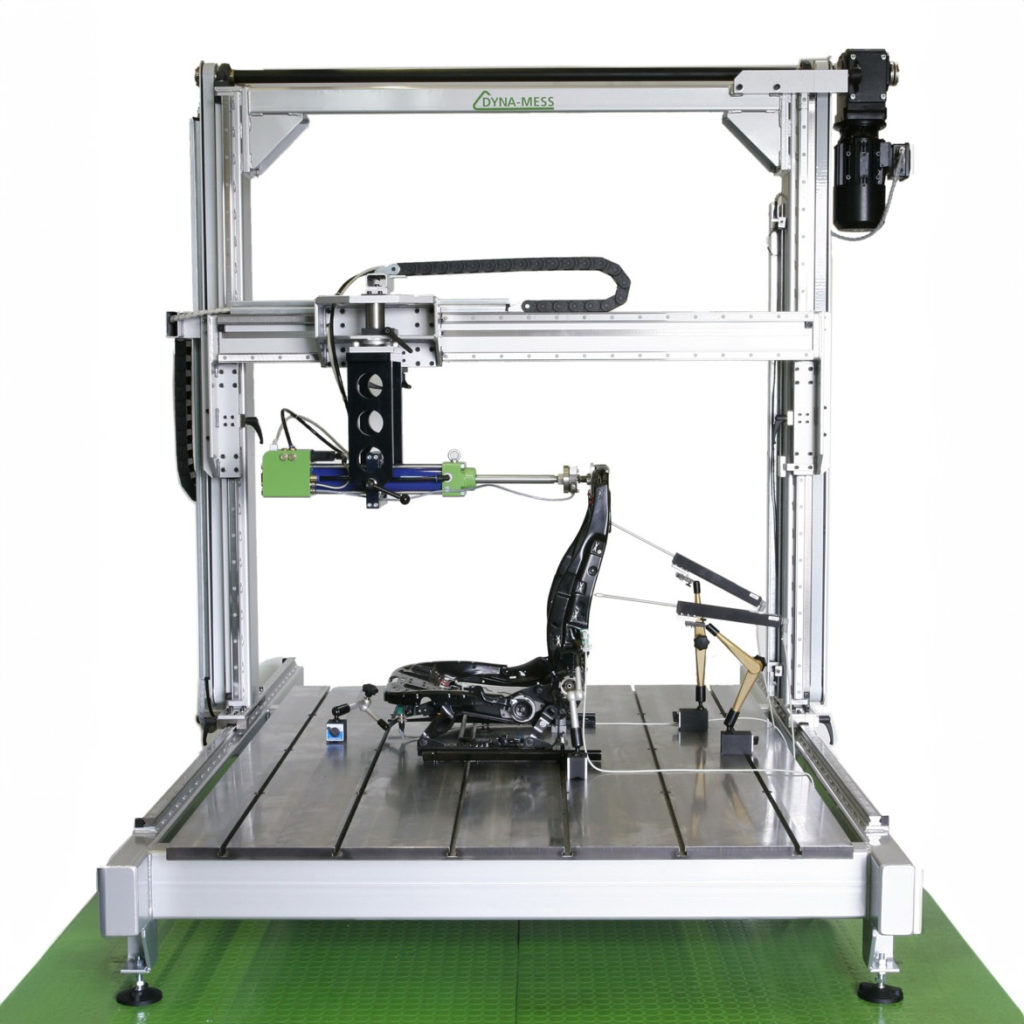

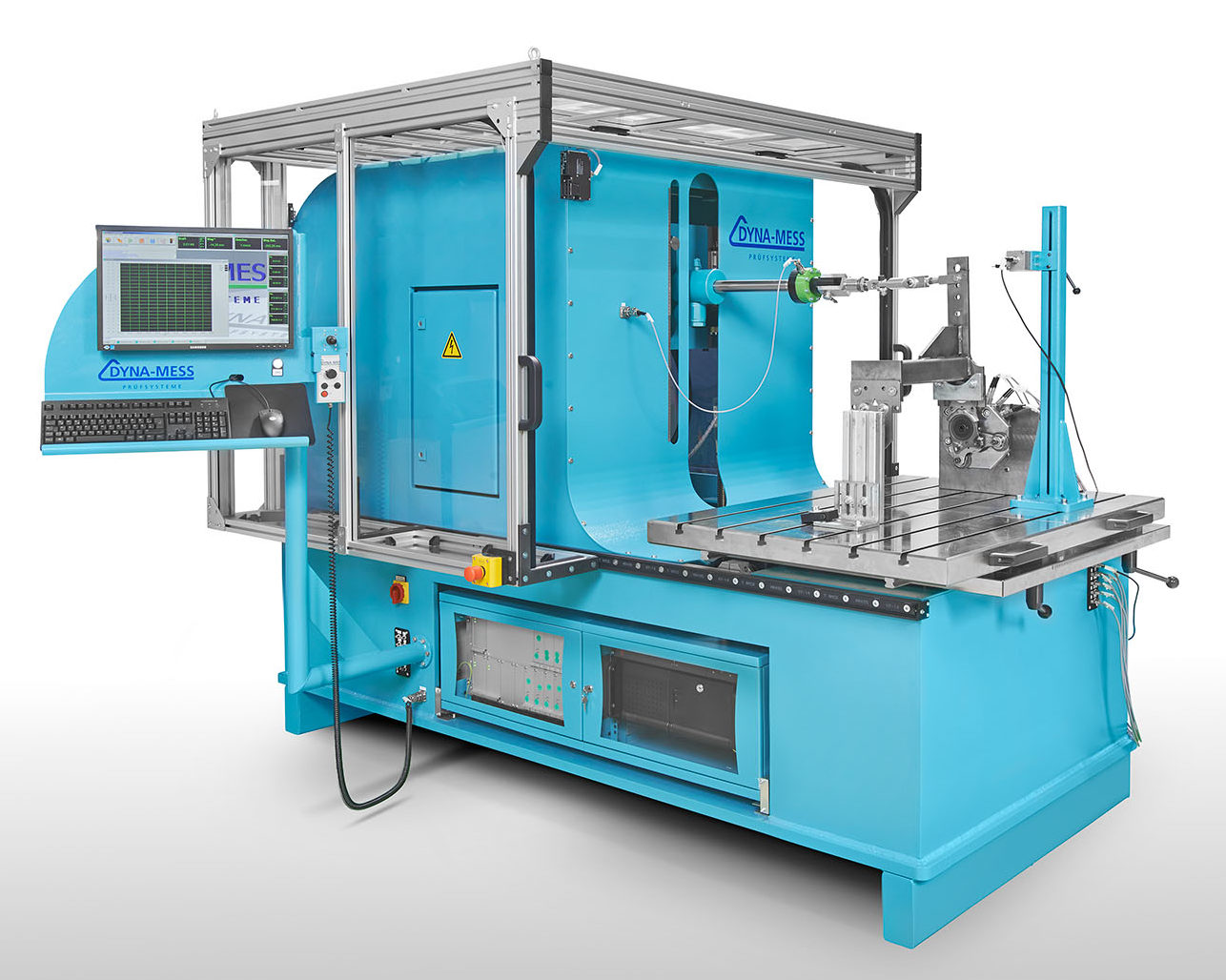

Universal wear simulator

for joint implants

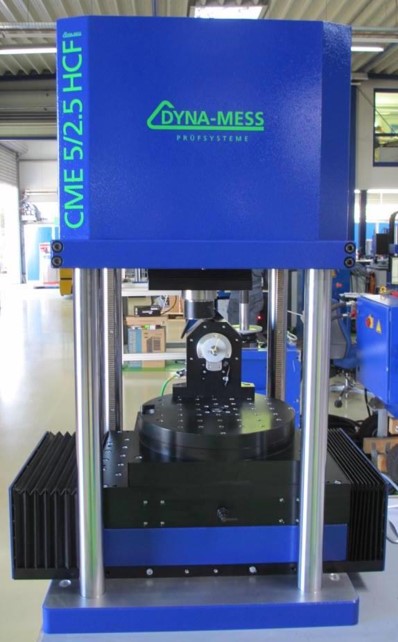

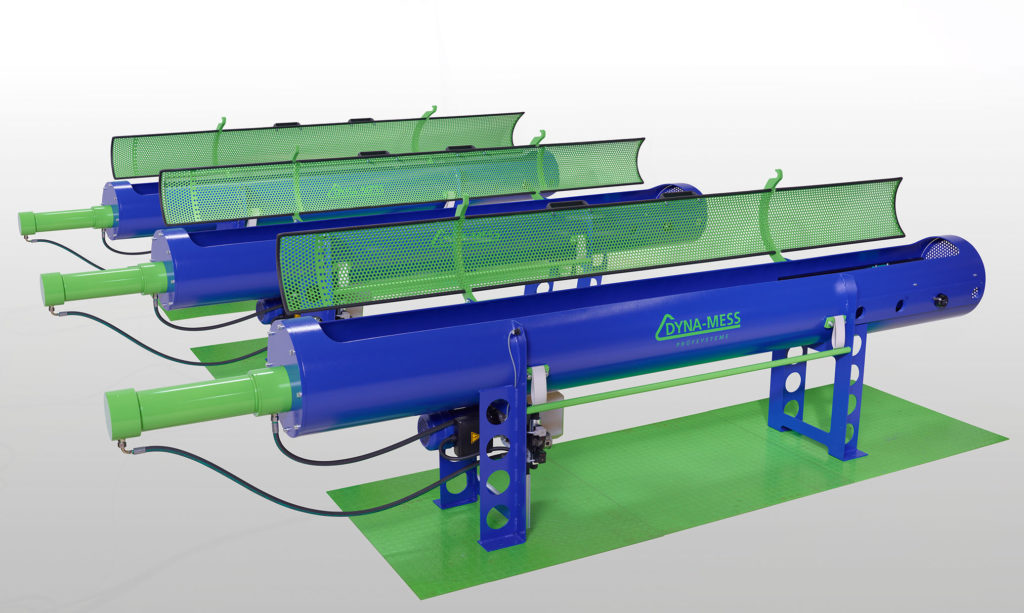

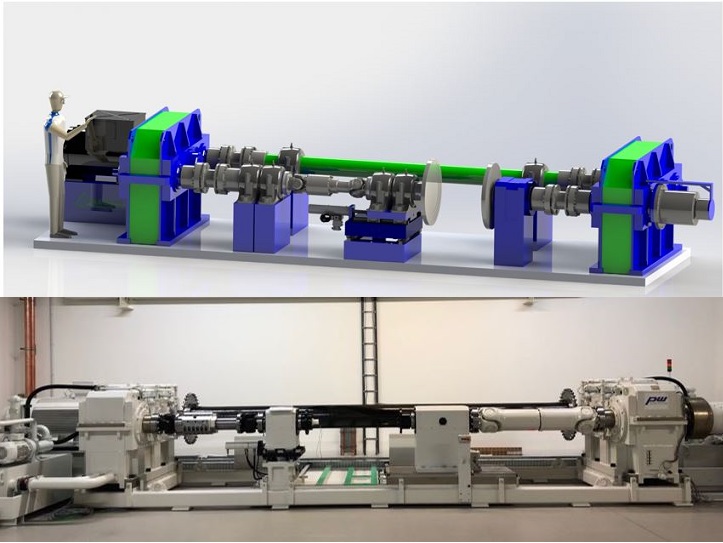

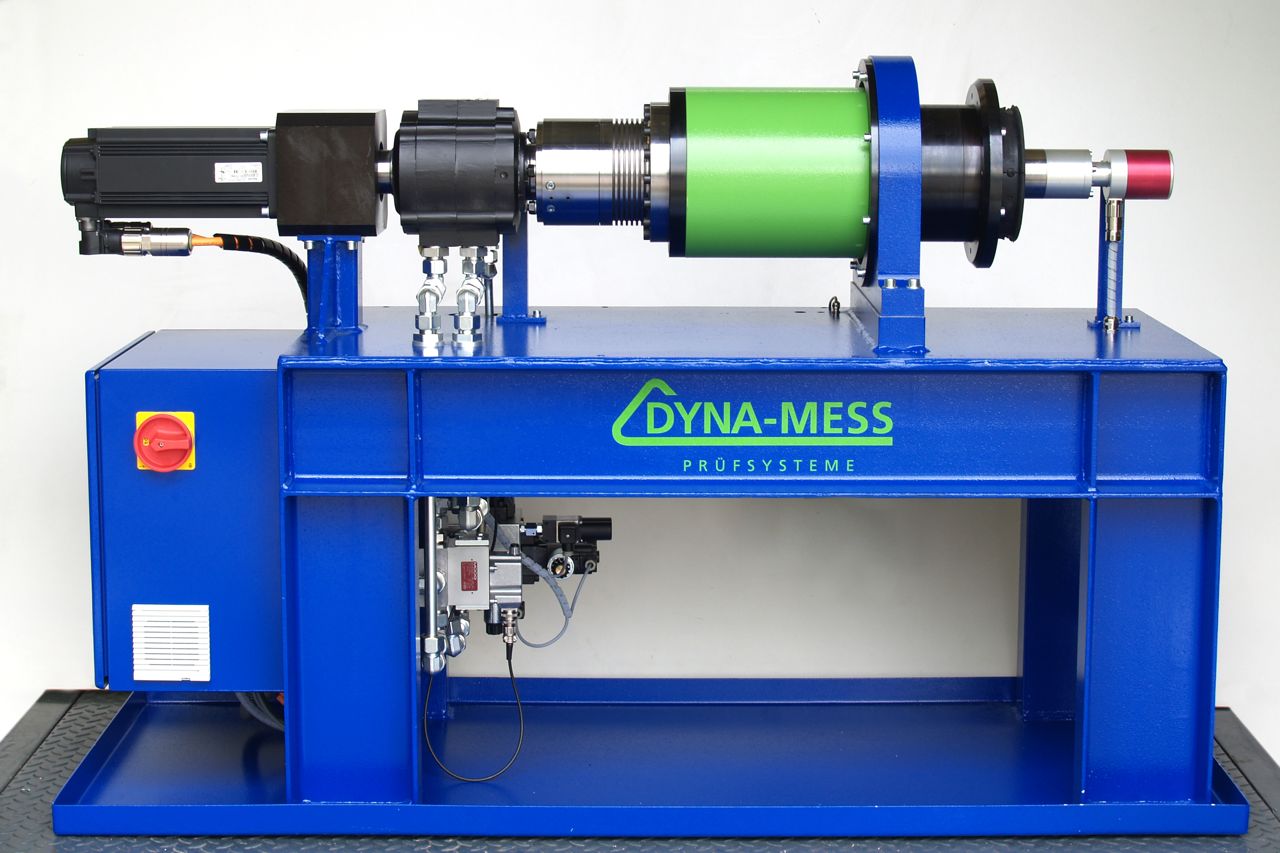

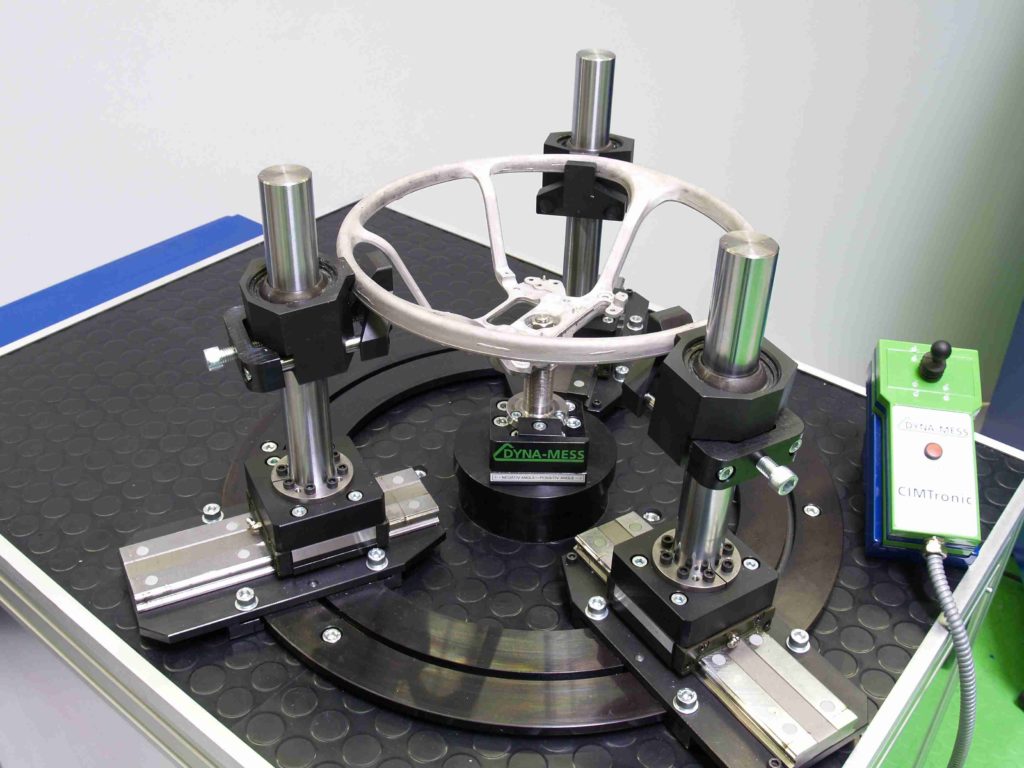

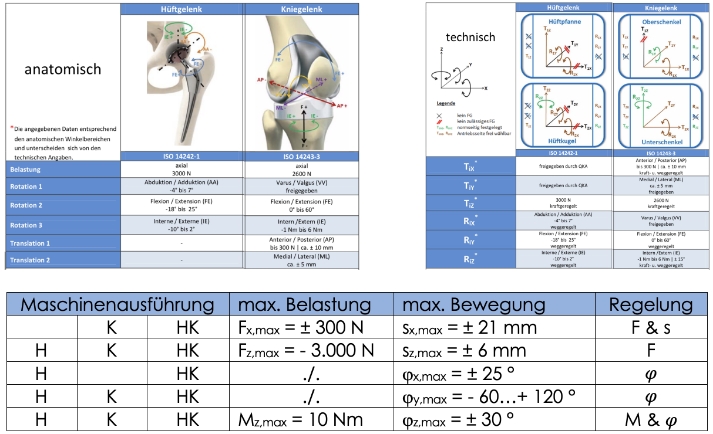

In close co-operation with universities, users and clinics, DYNA-MESS has developed the purely electrically driven wear simulator DYNA-EndoWear. A special feature of this machine is the ability to test both hip and knee implants in accordance with the DIN EN ISO 14242-1 (hip) and 14243-3 & 14243-1 (knee) standards, as well as shoulder and ankle endoprostheses.

We are DYNA-MESS. Test Systems.

Technical properties

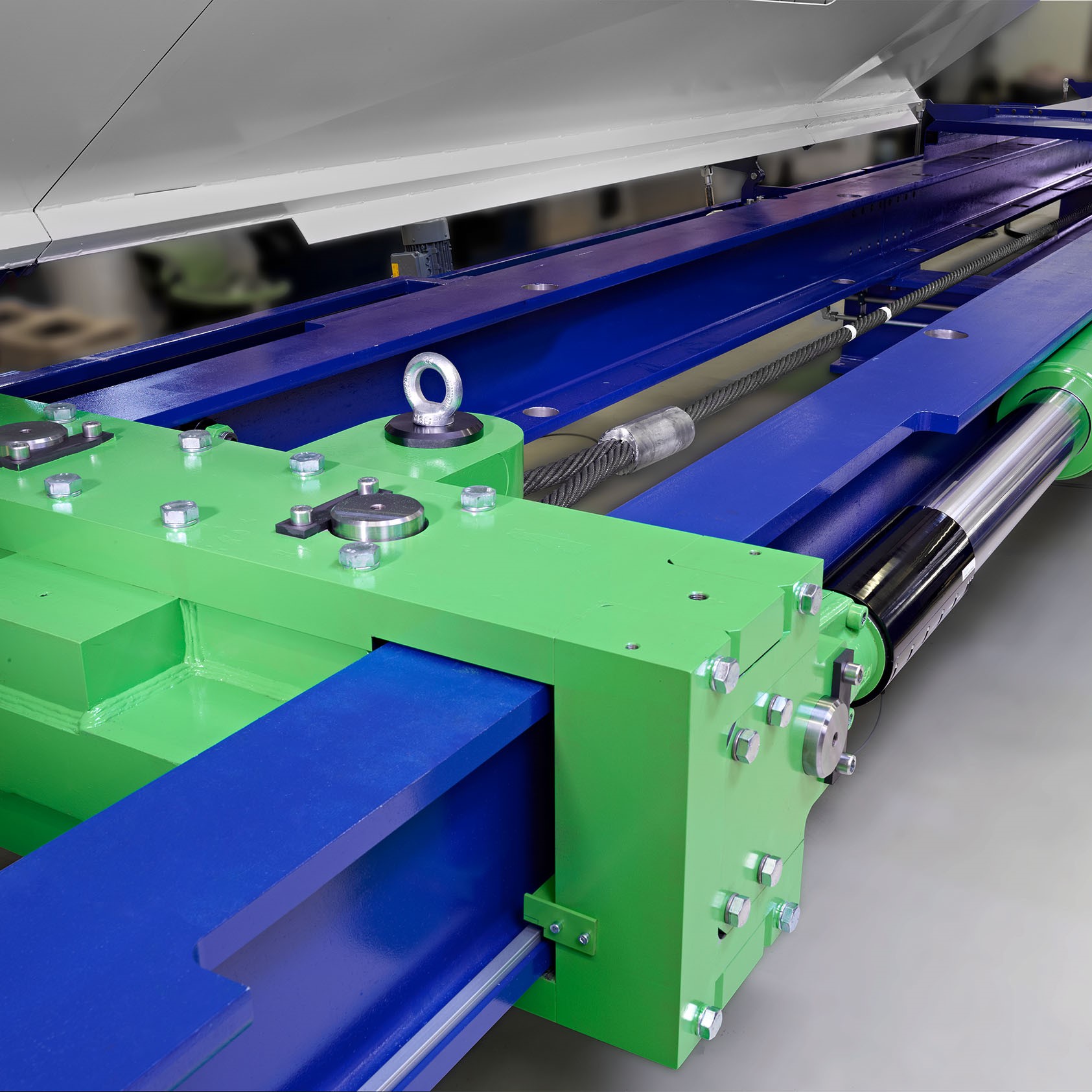

The servo-electric axes are installed in a compact machine that requires only a small footprint. Neither compressed air nor hydraulic oil is required for operation.

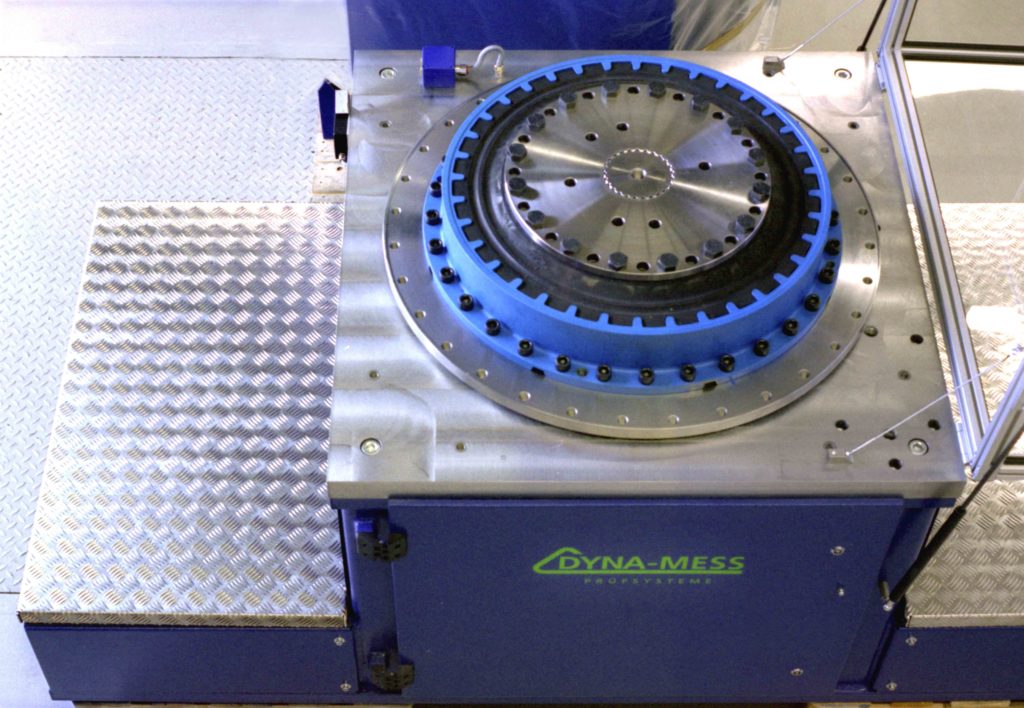

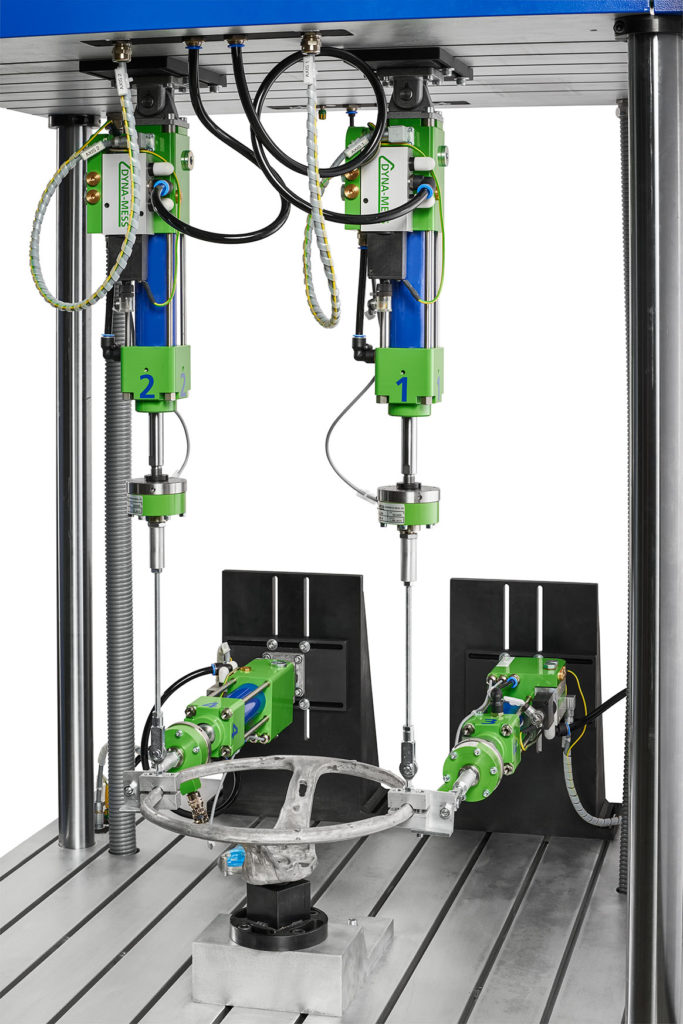

In addition to the three test stations, DYNA-EndoWear has a reference station for load-equivalent conditioning without the influence of wear.

Another special feature is the synchronised, independent control of the individual test stations using the DYNA-CLC high-performance controller. The proven DYNA-TCC software can be used to quickly and easily parameterise the tests in accordance with the above-mentioned standards.

One multi-component transducer measures forces and torques in all six degrees of freedom at each test station. Dynamic loads of Fx=300 N, FZ=3000 N and MZ=10 Nm are possible.

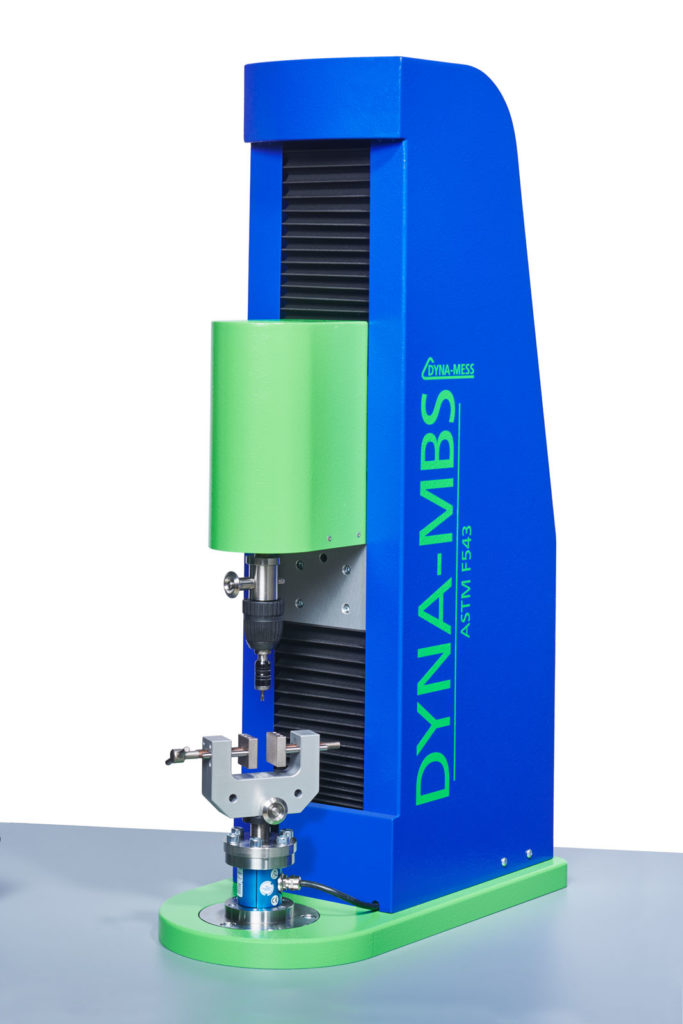

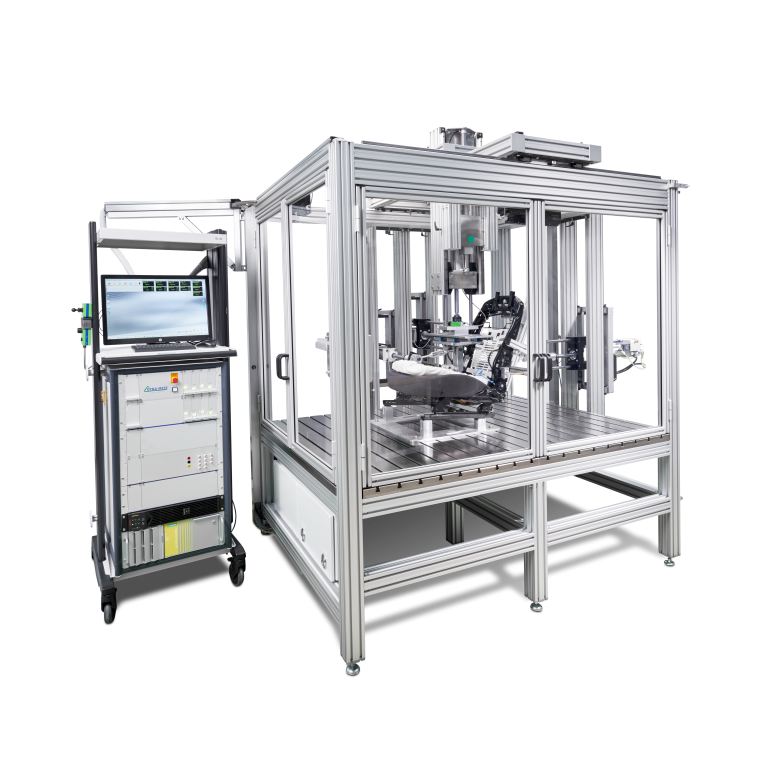

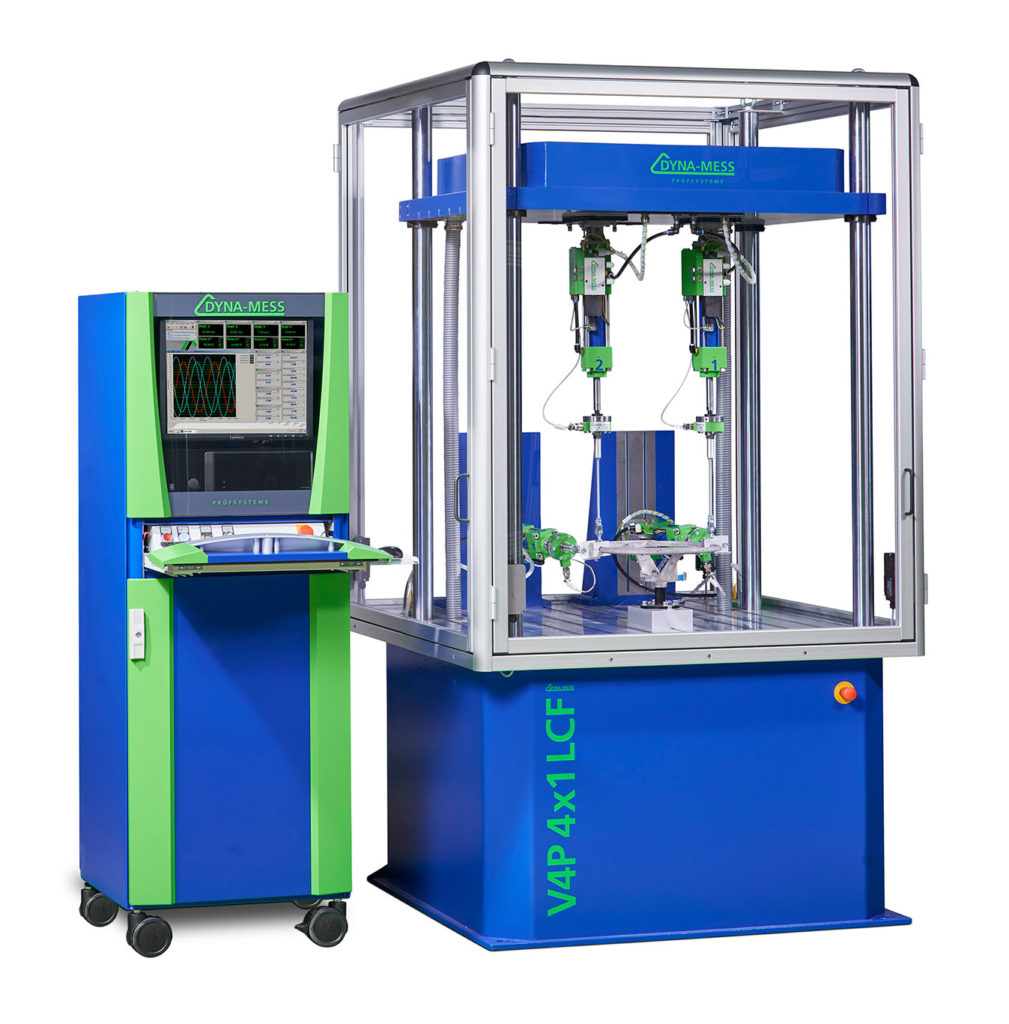

DYNA-EndoWear is available in three different versions:

- DYNA EndoWear 3H for tests on hip implants

- DYNA EndoWear 3K for tests on knee implants

- DYNA EndoWear 3HK for tests on hip and knee implants

The implants can also be tested in media (e.g. saline solution) at the individual test stations. Each station is equipped with a leakage sensor and the temperature is set and monitored.

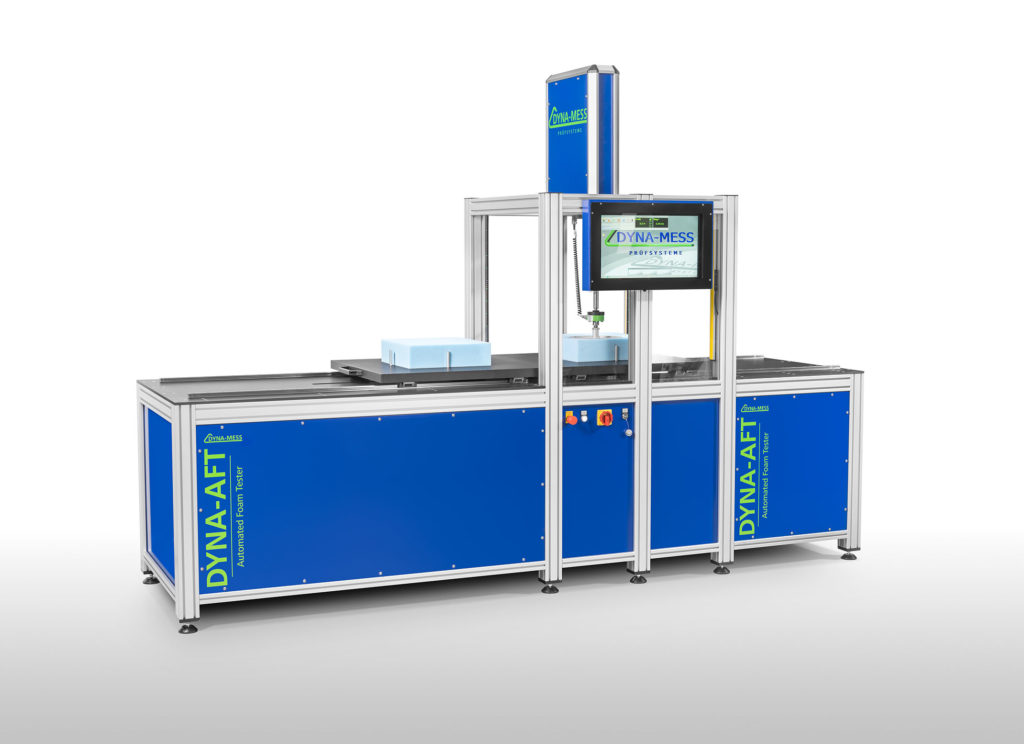

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems