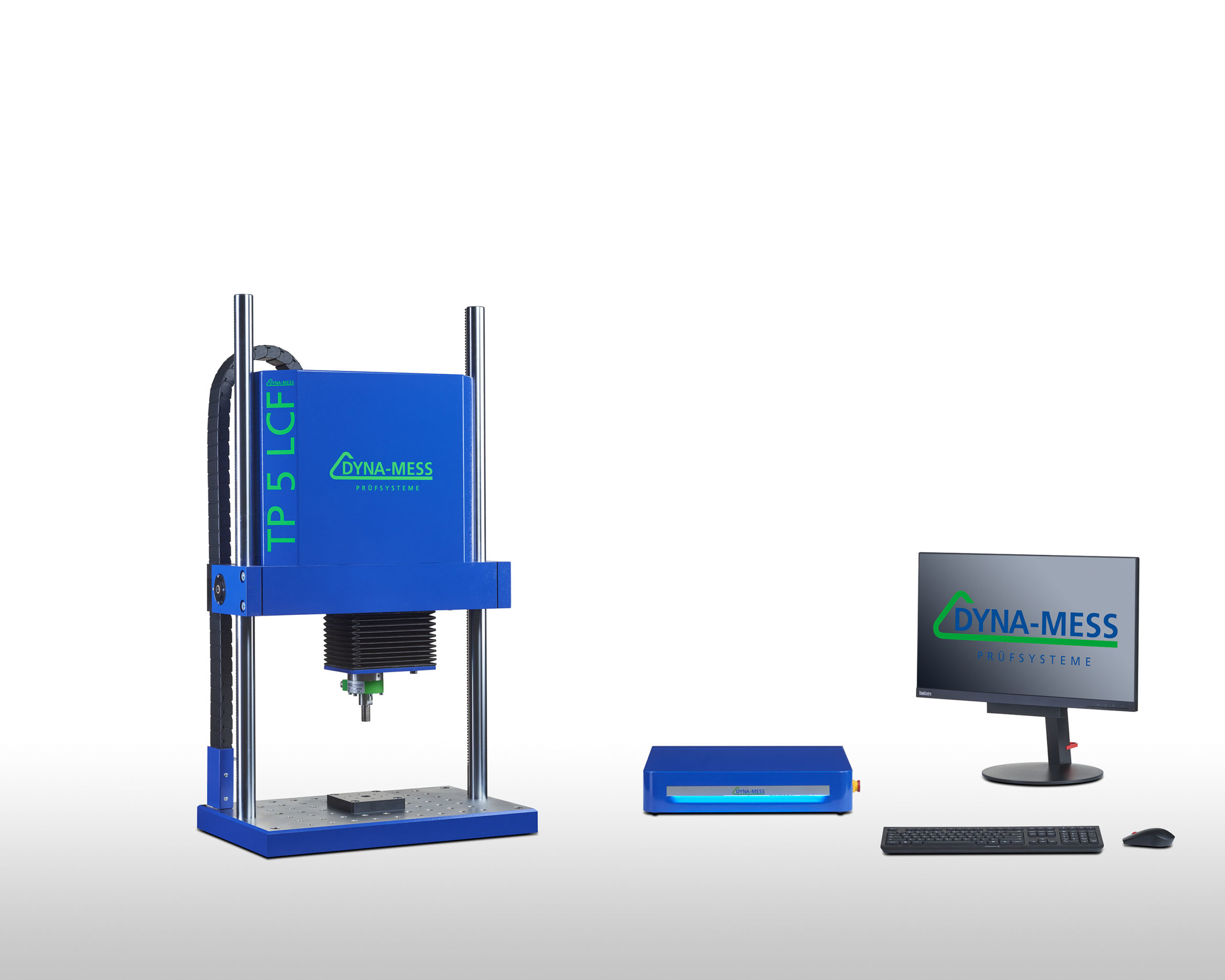

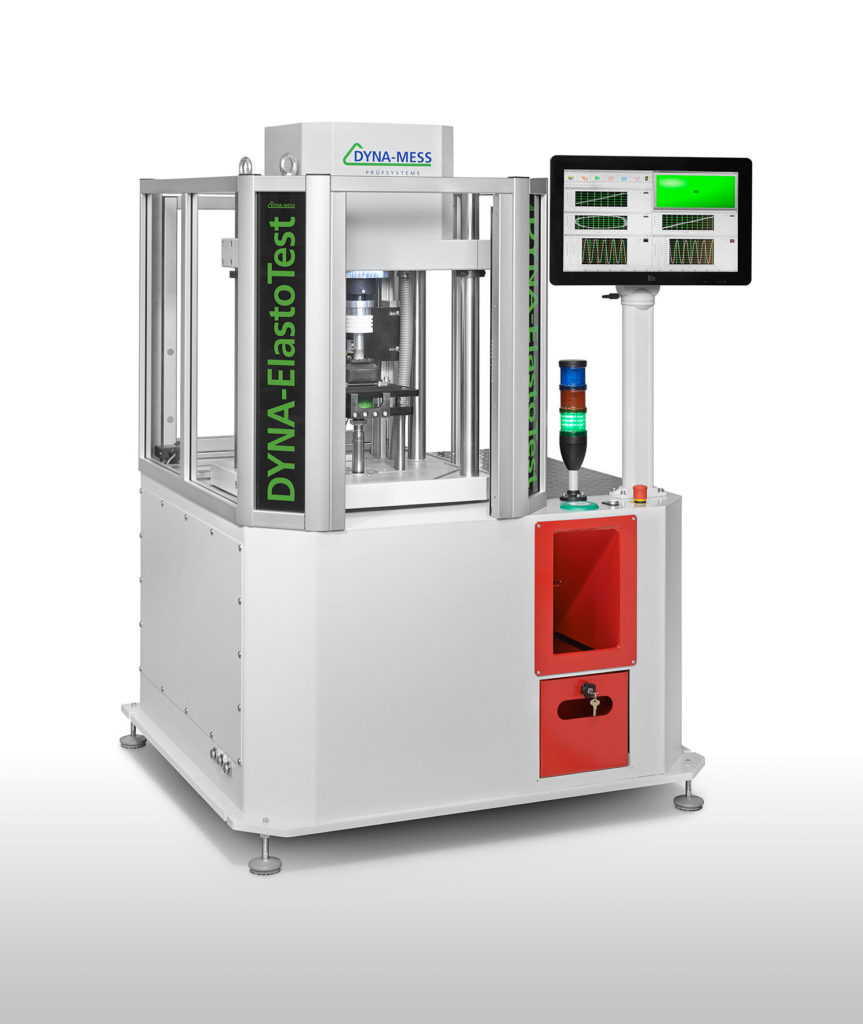

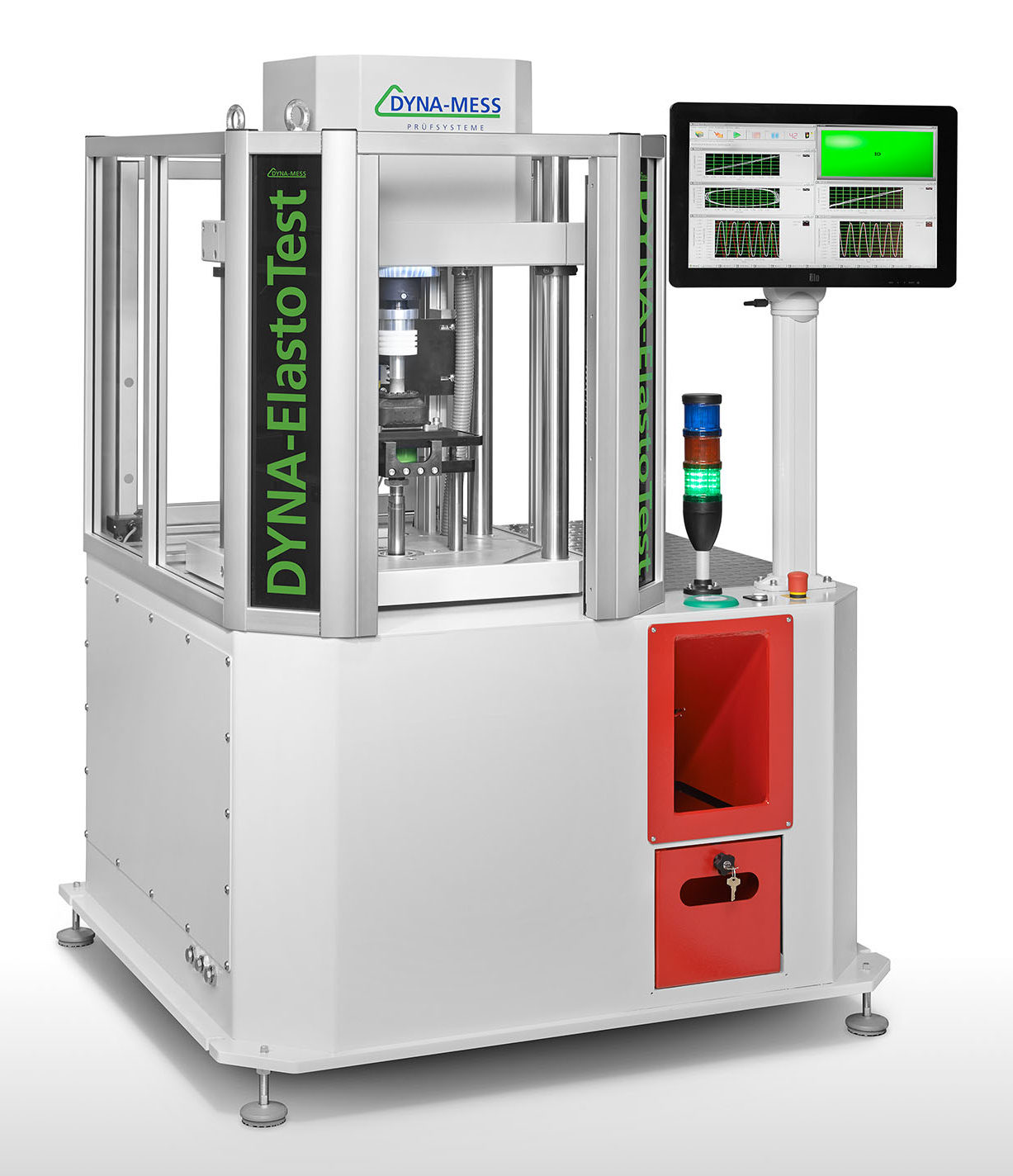

DYNA-ElastoTest

DYNA-ElastoTest

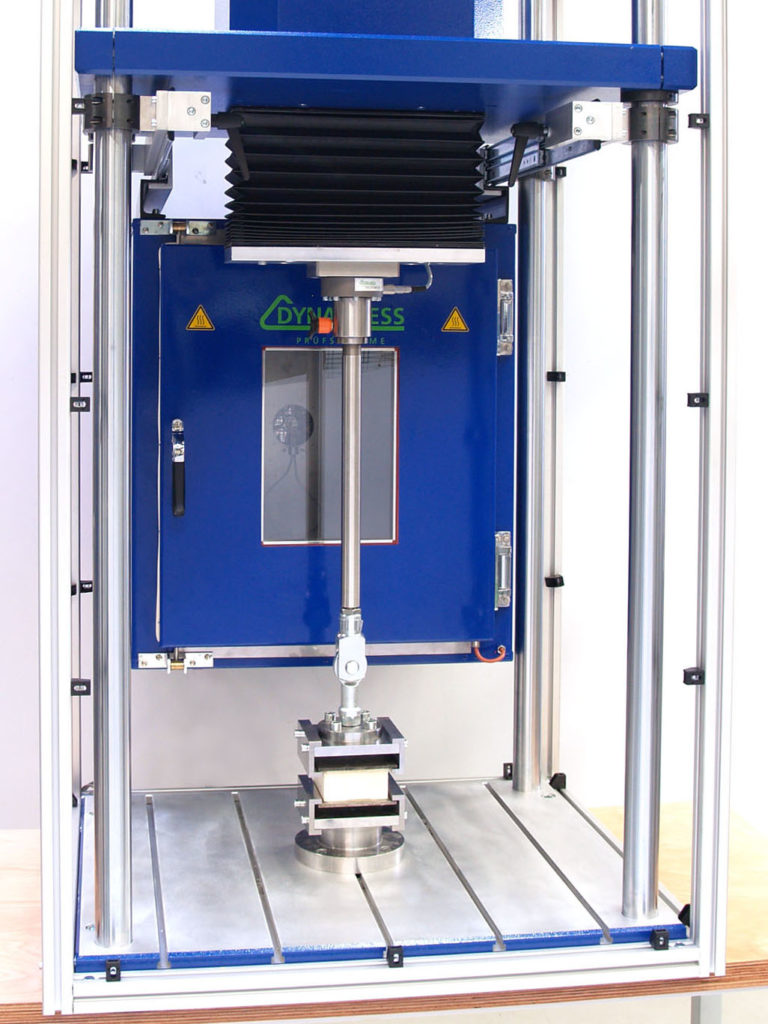

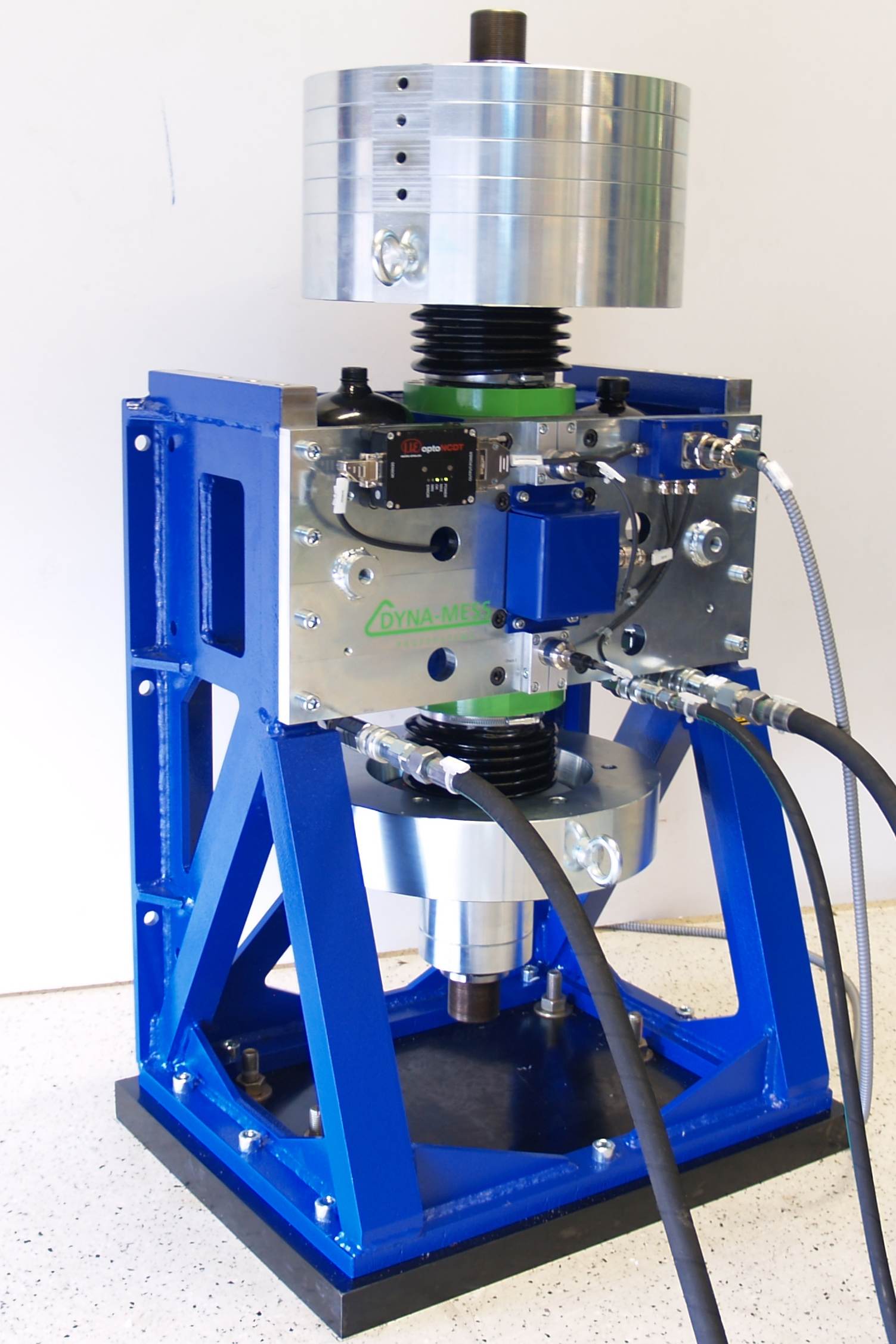

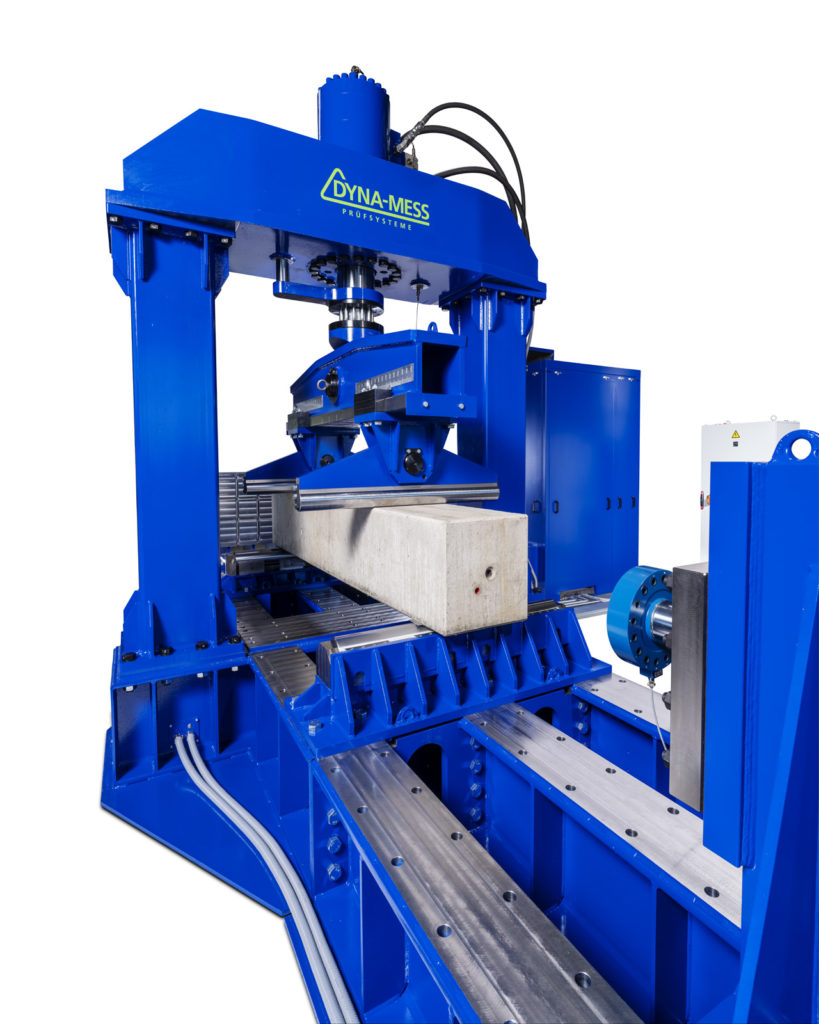

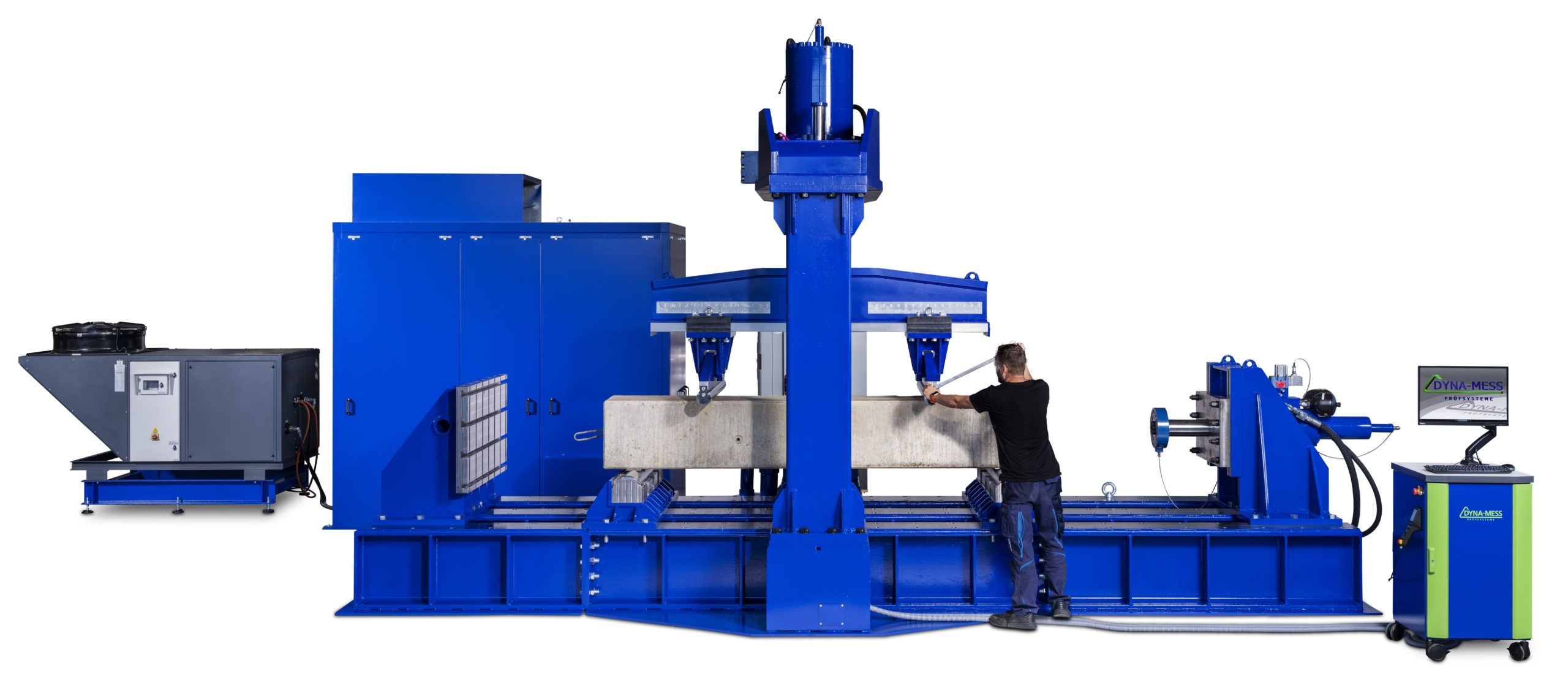

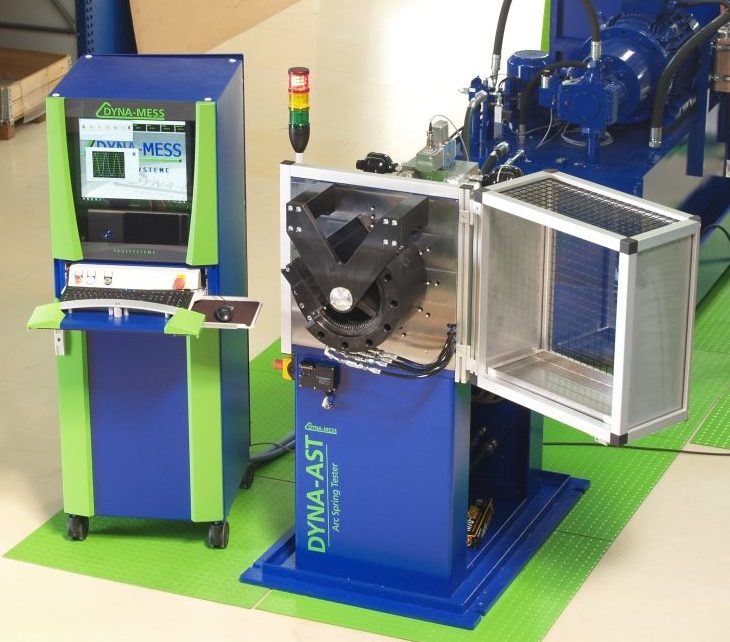

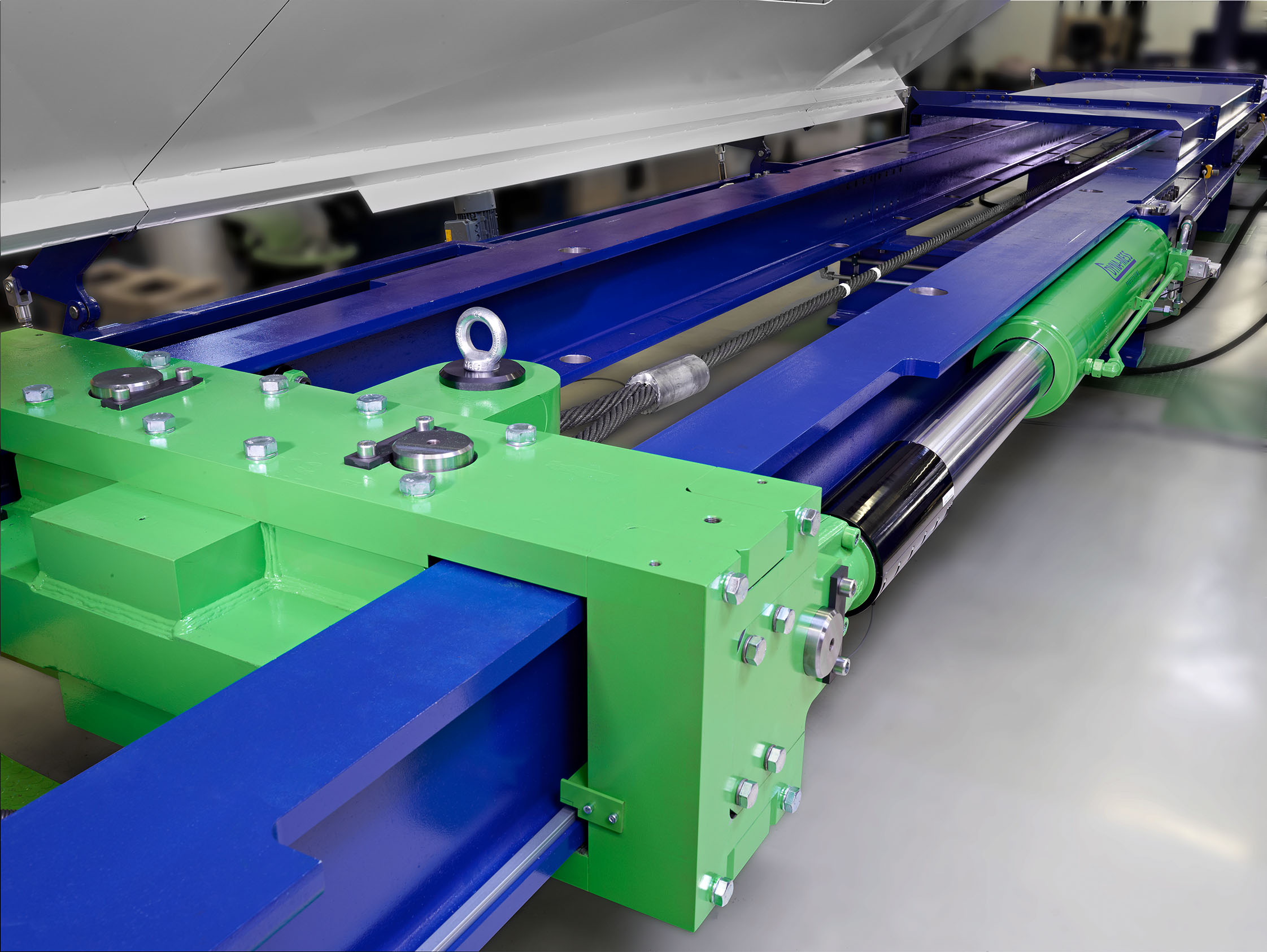

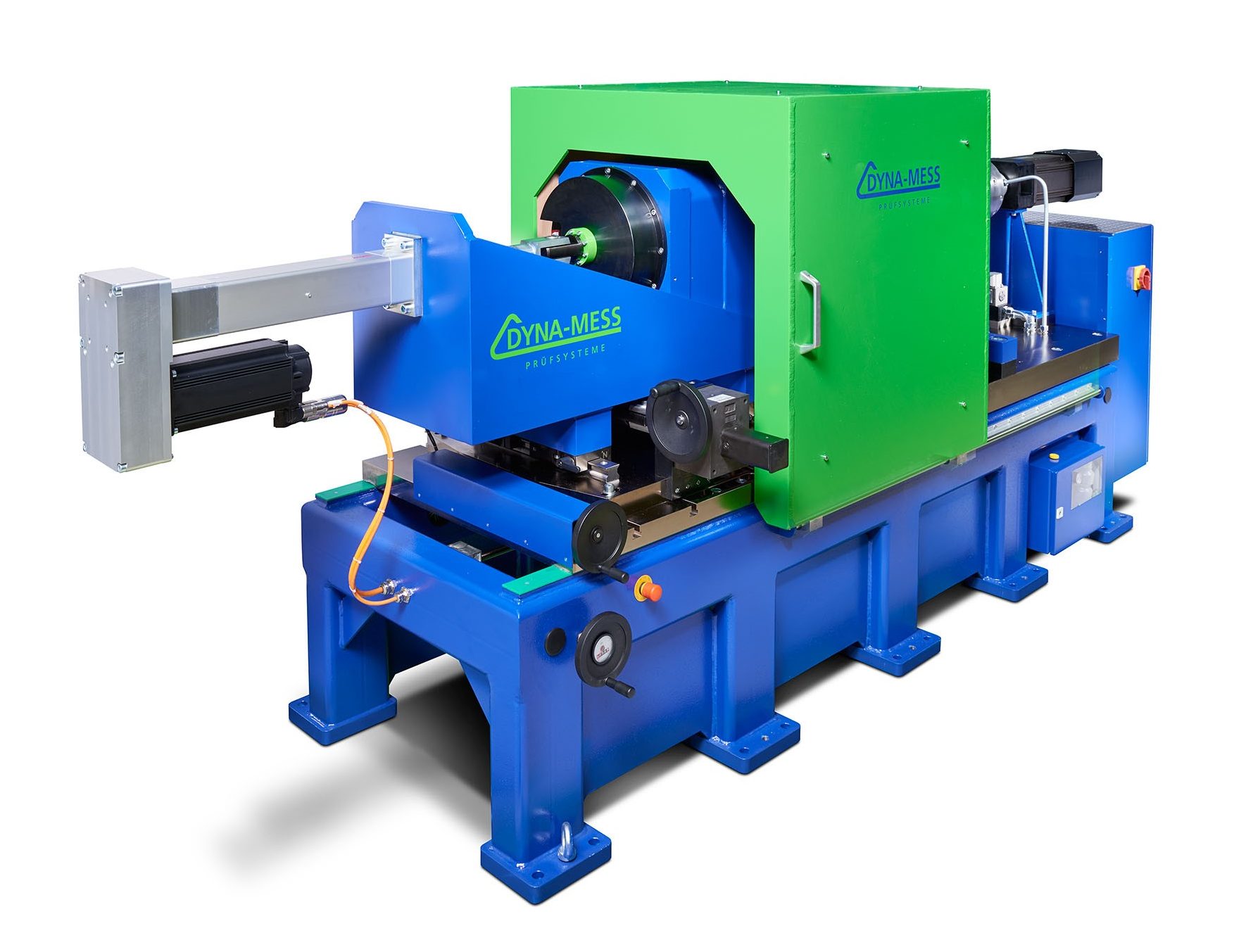

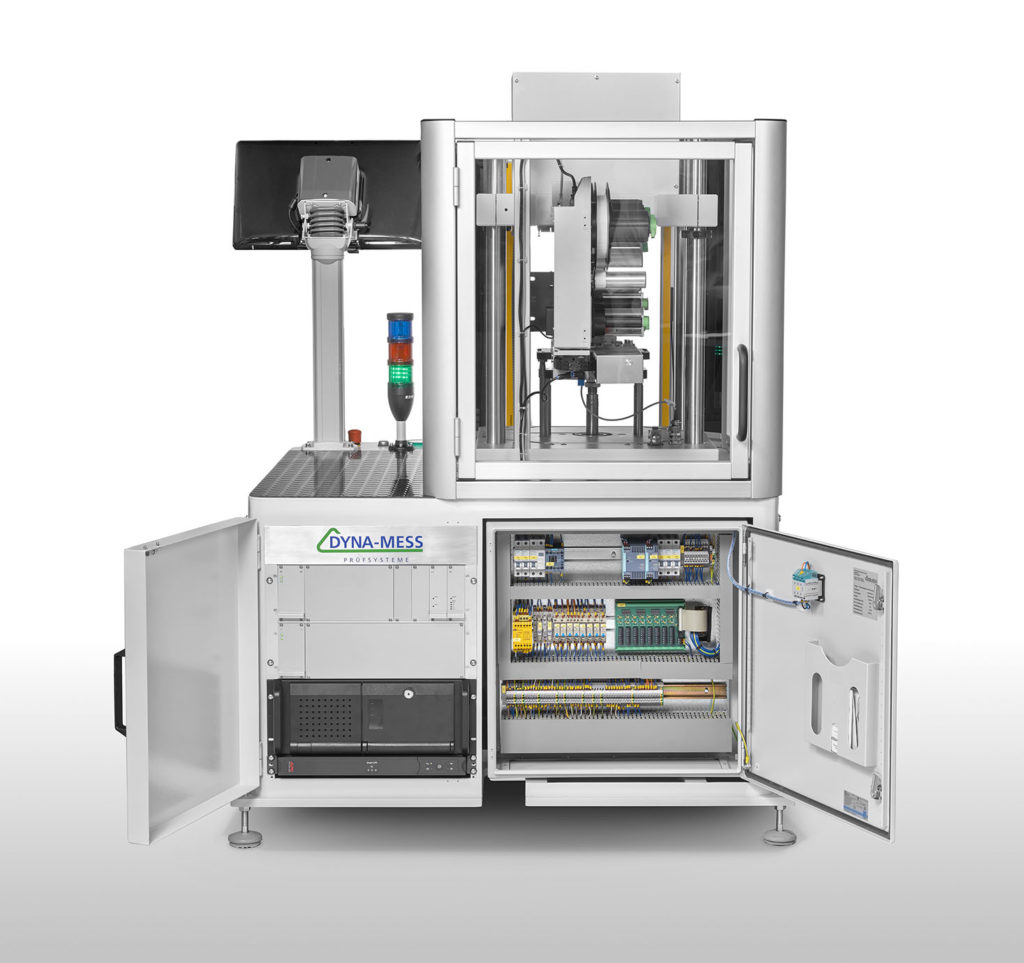

Compact end-of-line test station for the production-related assessment of static and dynamic characteristic values of rubber/metal elements. The DYNA-ElastoTest is a plug and play-capable test station with integrated controller.

We are DYNA-MESS. Test Systems.

Technical properties

Automatic mode

- Provision of standard interface signals to the higher-level control system

- Automatic test specimen detection

- Automatic sample selection

- Automatic test start

- Automatic data storage

- Shift and article file

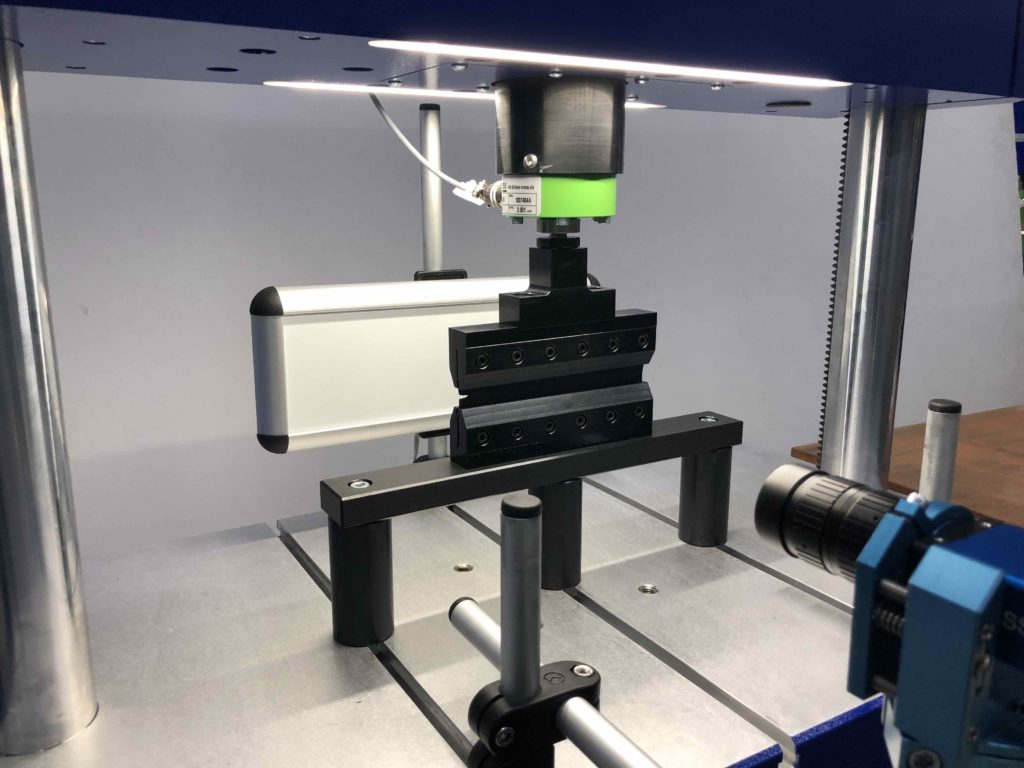

“Elastomer test” software module

- Test specimen conditioning

- Static tests

- dynamic tests

- Sweep tests/characterisation

- Graphical representation of signal curves and hysteresis curves

- Automatic determination of component parameters (static stiffness, dynamic stiffness, loss angle, work loss, damping and others according to different evaluation methods)

- Online display of the component characteristics and the iO/niO evaluation

Software module “Sweep test”

- Component characterisation using different evaluation methods

- Sweep tests in force/displacement control

- Display of dynamic characteristic values over frequency

Options

- Vacuum test

- Temperature-dependent OK/nOK evaluation

- DMC printer

- DMC scanner

- Laser labelling

- Needle embosser

- Further customised solutions can be implemented

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems