Rubber/metal elements

Rubber/metal elements

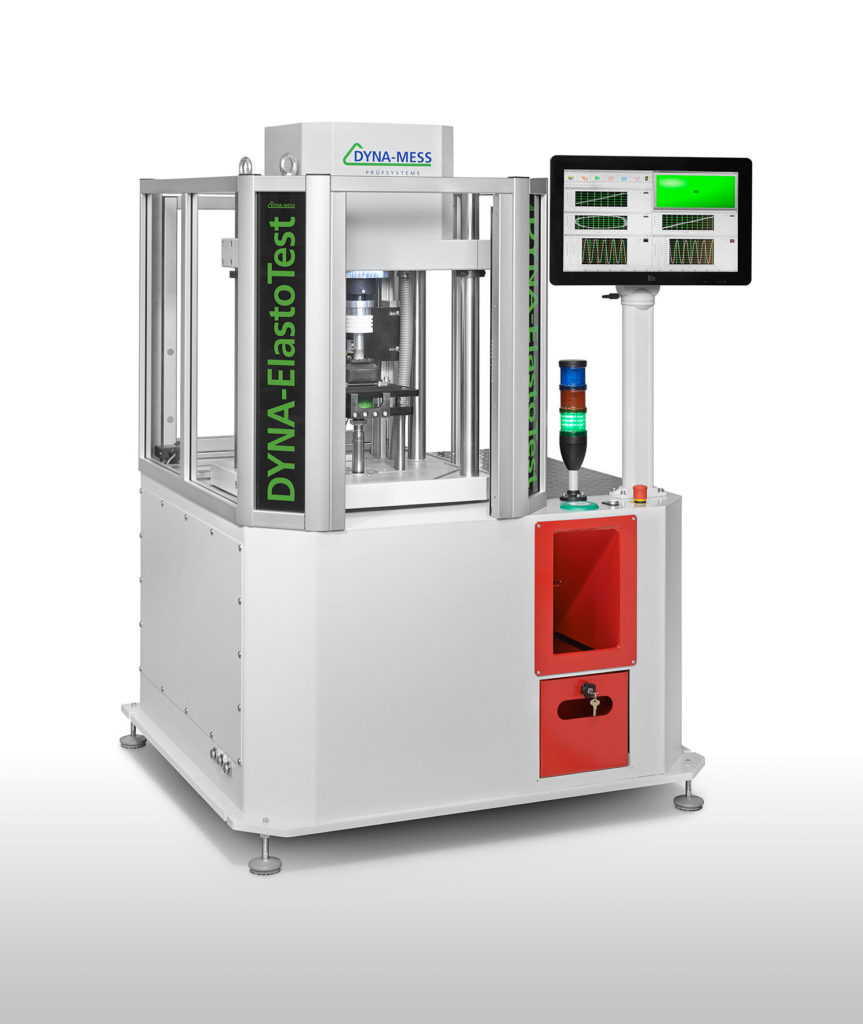

Elastomer components are tested both statically and dynamically. DYNA-MESS testing machines are used worldwide for both types of testing, both in development laboratories and in production for 100% testing at the end of production lines.

We are DYNA-MESS. Test Systems.

Tests

Static characteristic values

Measurement of characteristic curves and stiffnesses at different operating points

- Hysteresis

- Static rigidity

Dynamic testing

- Swing around defined preloads/displacements

- Hysteresis

- Dynamic stiffness

- Loss angle

- Damping work

- Durability

Static limit load test

- Load increase until the damper fails (breakage …)

Sweep test

- Dependence of the dynamic spring rate on the excitation frequency

- Dependence of the dynamic spring rate on the exciter amplitude

- Dependence of attenuation on frequency and amplitude

Service life tests

- Dynamic endurance test with known excitation frequency

- Investigation of the dynamic long-term behaviour (e.g. dynamic creep)

- Assessment of damage patterns (fatigue, vulcanisation detachment…)

Torsion tests

Cardanic tests

Laboratory testing and series testing

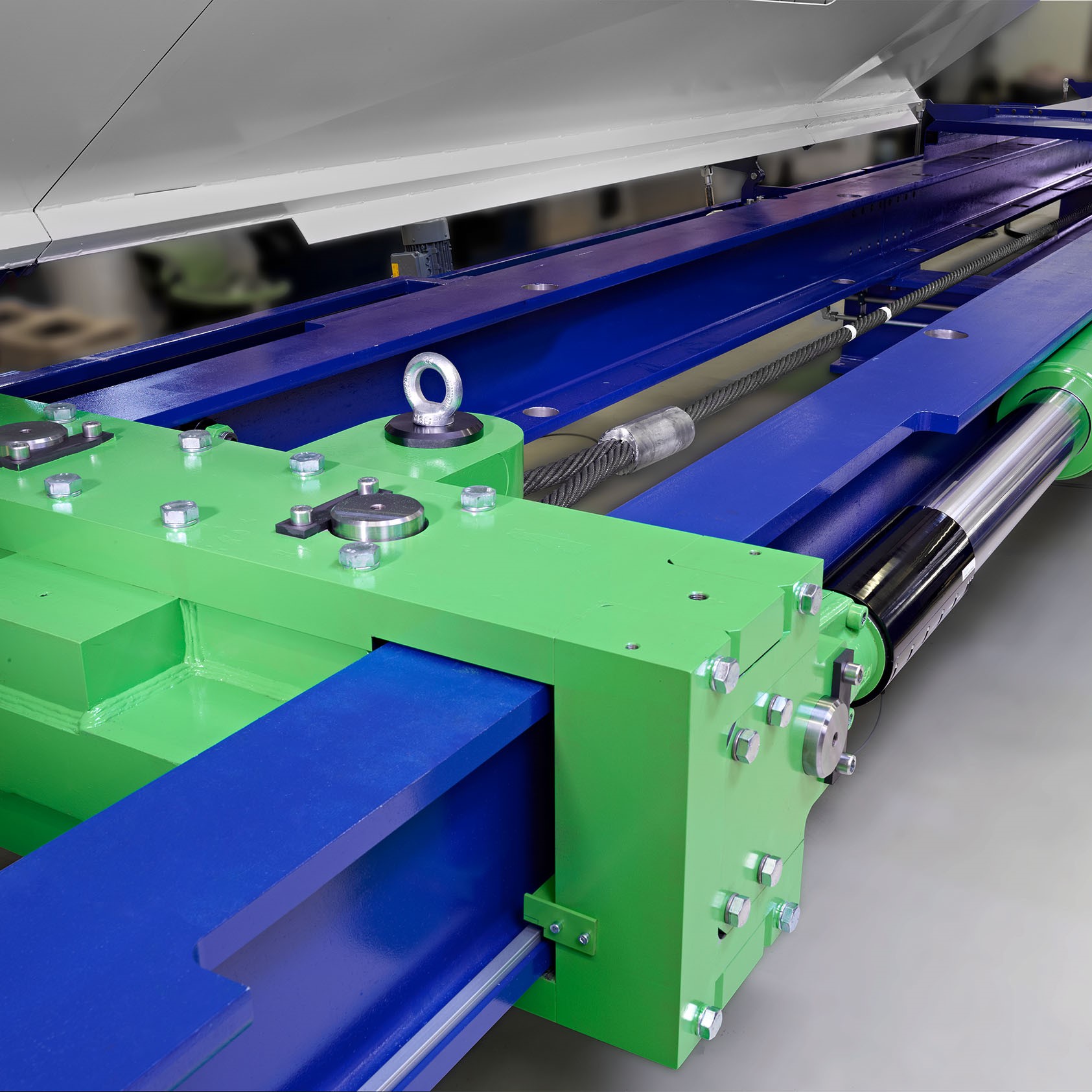

On the one hand, the test benches can be designed as testing machines for individual tests in research and development or for quality testing during production. On the other hand, production-integrated test stations (DYNA-ElastoTest) are also possible, which are equipped with appropriate feed systems for the test specimens (engine mounts, chassis mounts, etc.) and standardised interfaces for communication with the production line.

Cost-effective servopneumatics, powerful servohydraulics and flexible servoelectrics

Depending on the test requirements (test force, frequency, stroke), the systems are designed as servo-pneumatic, servo-hydraulic or servo-electrically controlled testing machines. The more cost-effective servo-pneumatic systems can be used at frequencies of up to approx. 35 Hz. Servo-hydraulic systems are used for test specifications up to several hundred hertz test frequency. Energy-efficient, low-maintenance and low-noise servo-electric systems are used for tests up to 150 Hz.

SUITABLE PRODUCTS

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems