Seats

Seats

A large number of mechanical tests are carried out on vehicle seats. Standardised DYNA-MESS test rigs and axes are preferably used for endurance tests and to determine play and stiffness.

We are DYNA-MESS. Test Systems.

Tests

Fatigue tests

Endurance tests on vehicle seats are carried out using classic vibration tests, multi-stage/block tests or cyclic ramp tests. Both the metallic seat structures and fully upholstered seats are analysed. The force is applied via back and buttock dummies in order to reproduce a load that is as close to reality as possible.

Multi-axes experiments

Multi-axis tests are easy to realise with the help of the DYNA-MESS test axes. The testing software is configured for several axes and then ensures that the overall test is carried out correctly. In multi-axis tests, the correct sequence of loads or – in the case of simultaneous loading by several axes – the temporal synchronisation of the axes is important.

Tensile and compressive loads with a test axis

Many test specifications stipulate alternating loads in two directions. Thanks to the servo technology used, these loads can be applied with just one test axis. The axis-integrated force and displacement measurement ensures that the desired loads and positions are approached precisely.

Seat adjustments

In addition to testing the seat structures, test axles are used for the continuous actuation of seat adjustments (seat length adjustment, seat height adjustment). These continuous function tests can be carried out in combination with electrical adjusters (backrest adjustment, etc.). The DYNA-MESS test software enables simple control of these motors.

Play and stiffness measurement

To determine the backrest play and seat rigidity, the seats are subjected to a quasi-static load up to a test force. Additional displacement sensors (displacement sensors, laser displacement measuring systems, etc.) are used to measure the deformation of the seat structure at defined positions.

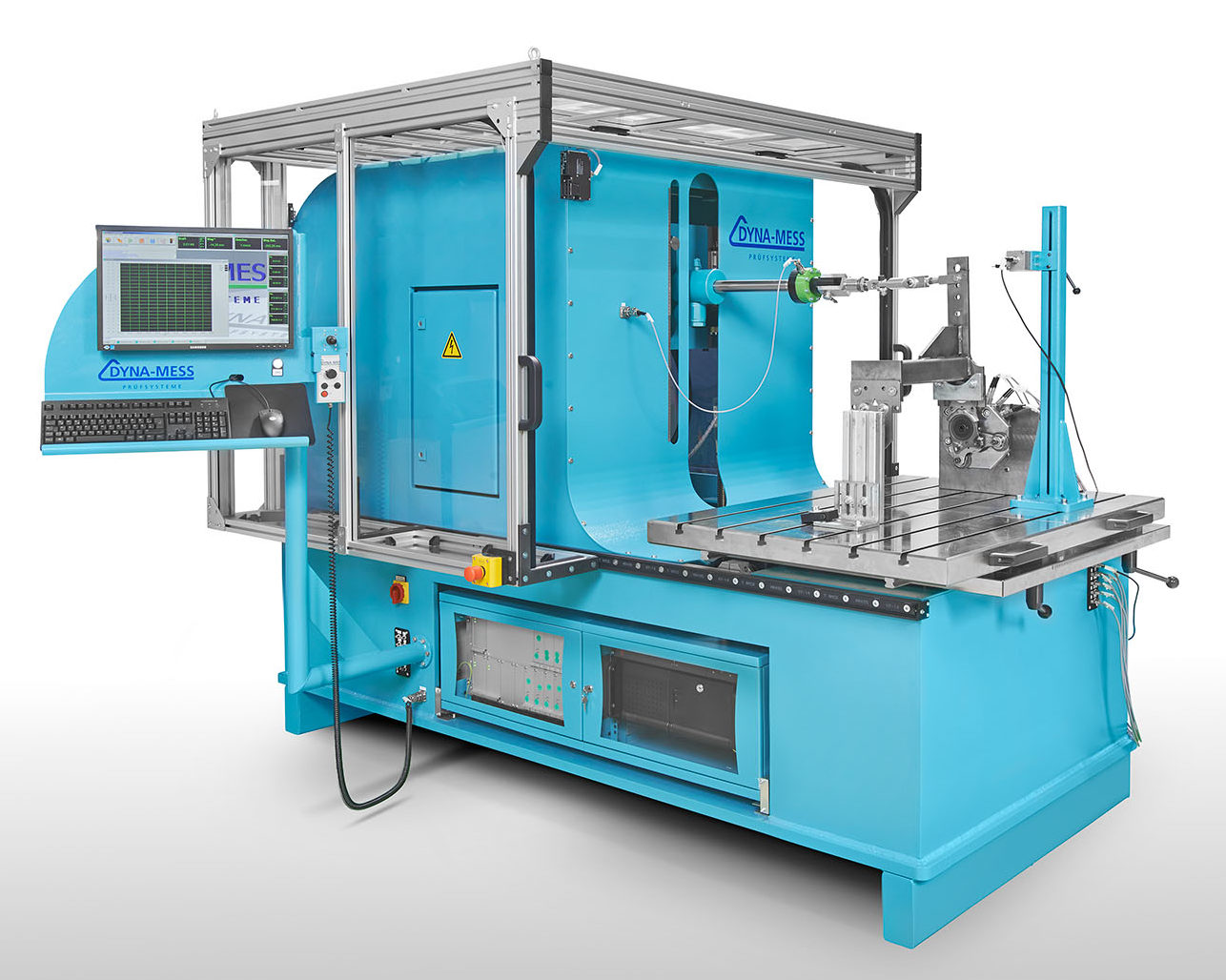

DYNA-EVP: Ehra tester

DYNA-MESS has developed the DYNA-EVP, an Ehra tester for car seats, for operational load impact tests.

- Portal frame with 3 load units (3 front seats or one rear seat)

- Vibratory plate for vertical movement, with additional horizontal movement

- Dynamic Ehra signal

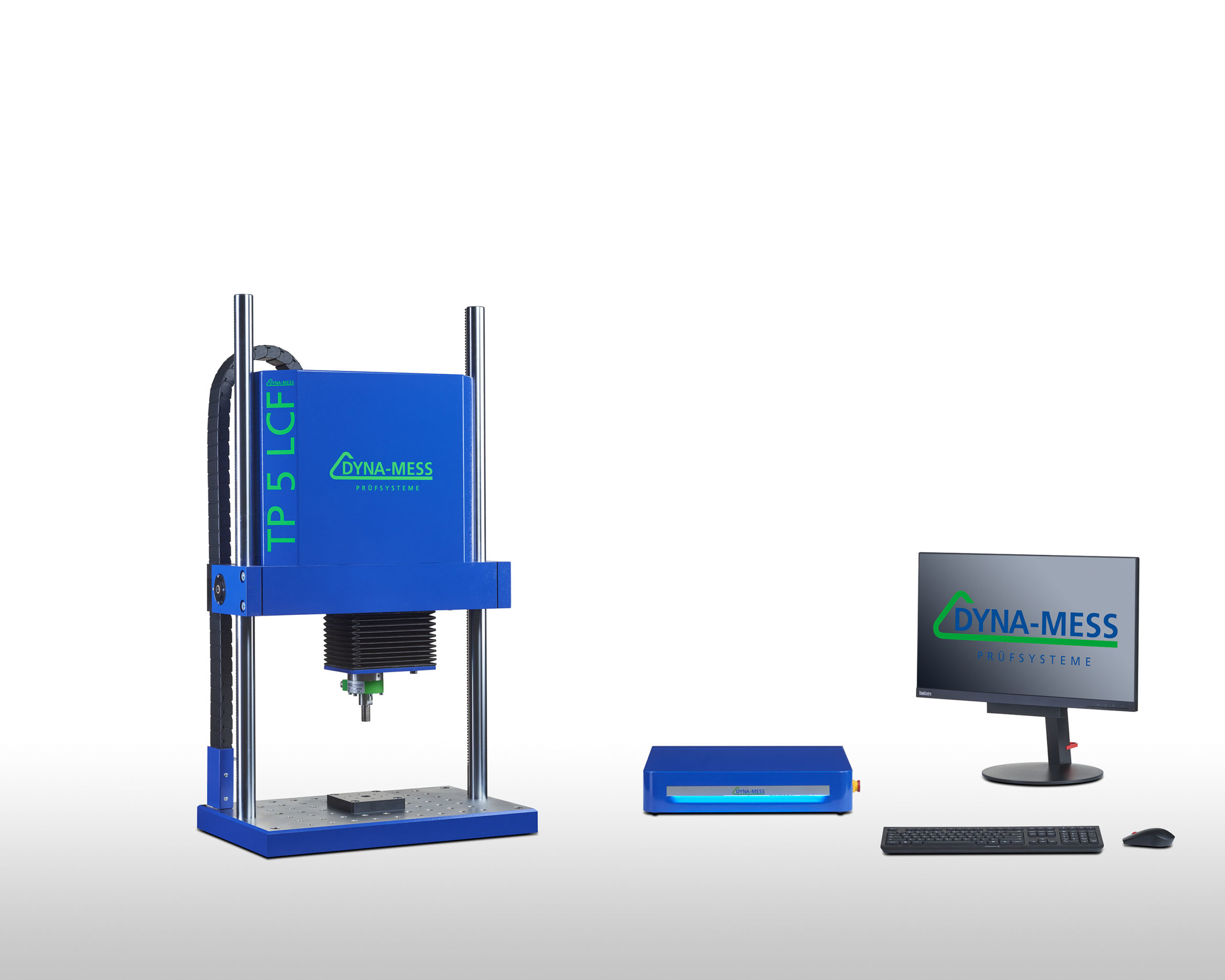

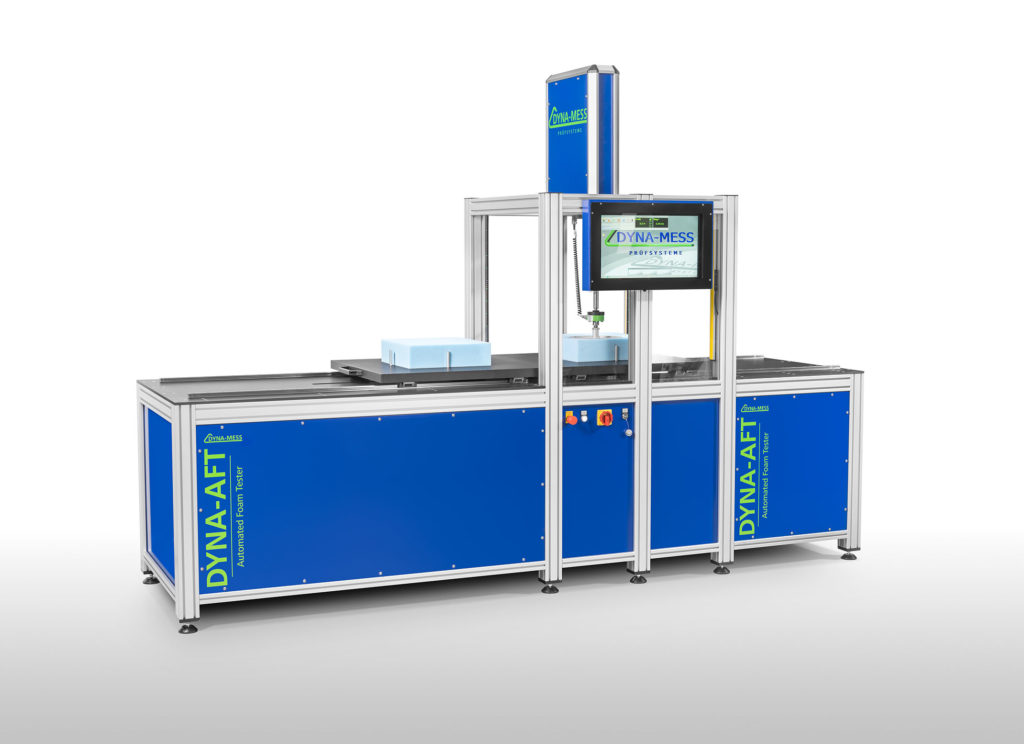

DYNA-AFT: Automated Foam Tester

Foam tests according to ISO 2439, ISO 3385, ISO 3386 – 3 variants possible

- Standard

- Standard +

- Automatic testing

Technical data

- Electric drive

- Light curtain

- PC and electronics integrated

- Customised software

SUITABLE PRODUCTS

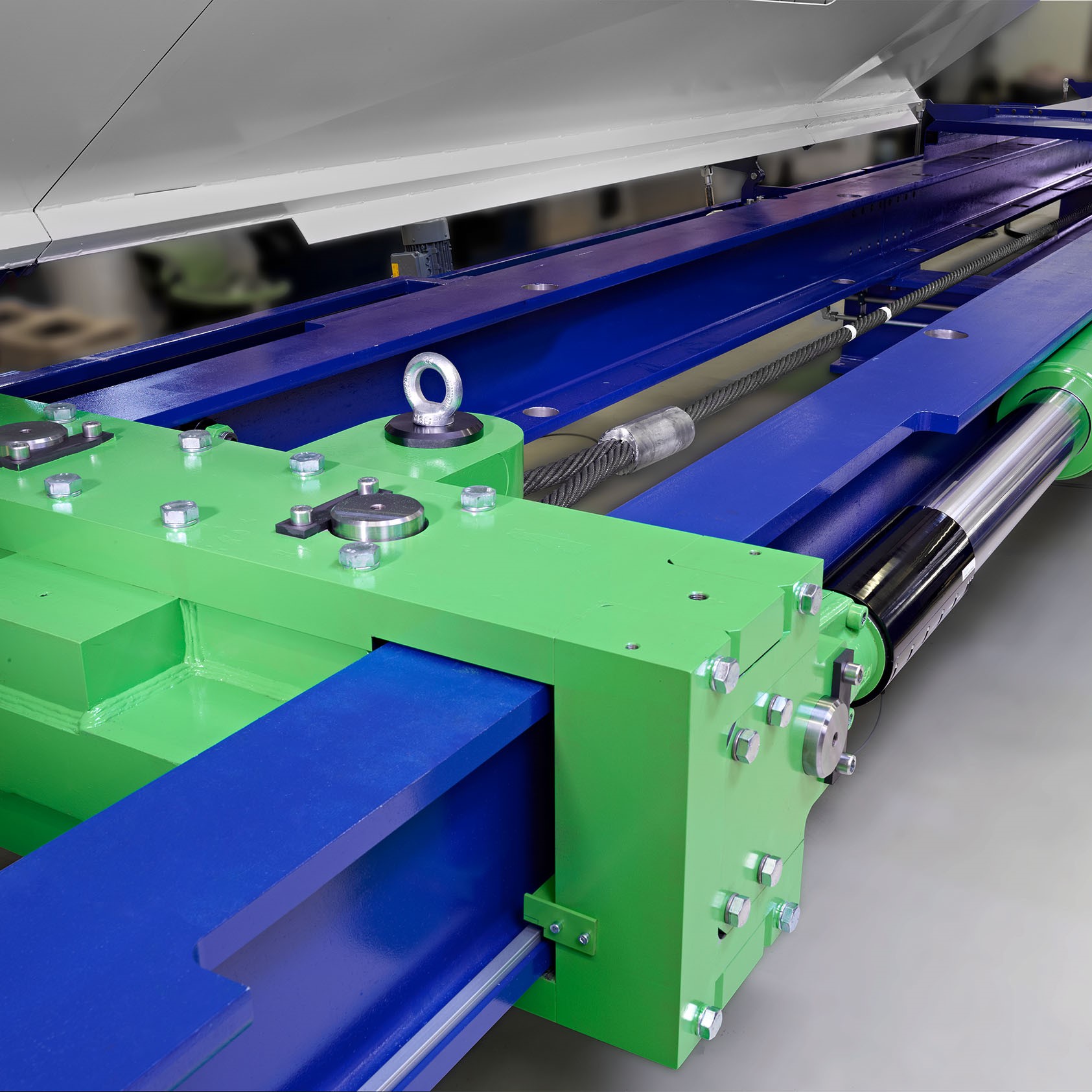

DYNA-FTT + DYNA-SST

The FastTension Tester DYNA-FTT and the StaticStrength Tester DYNA-SST are test devices for testing the recliners of car seats.

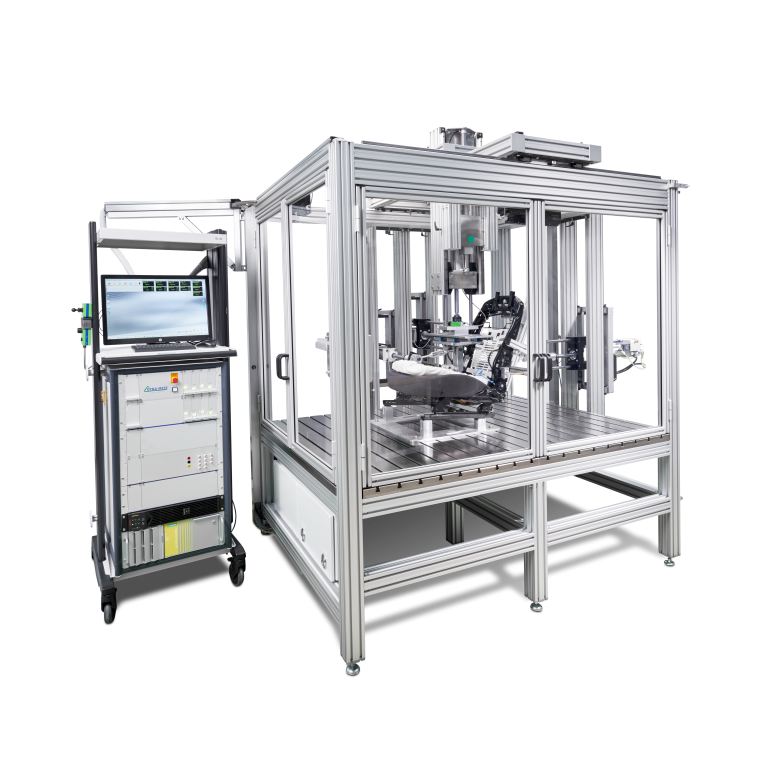

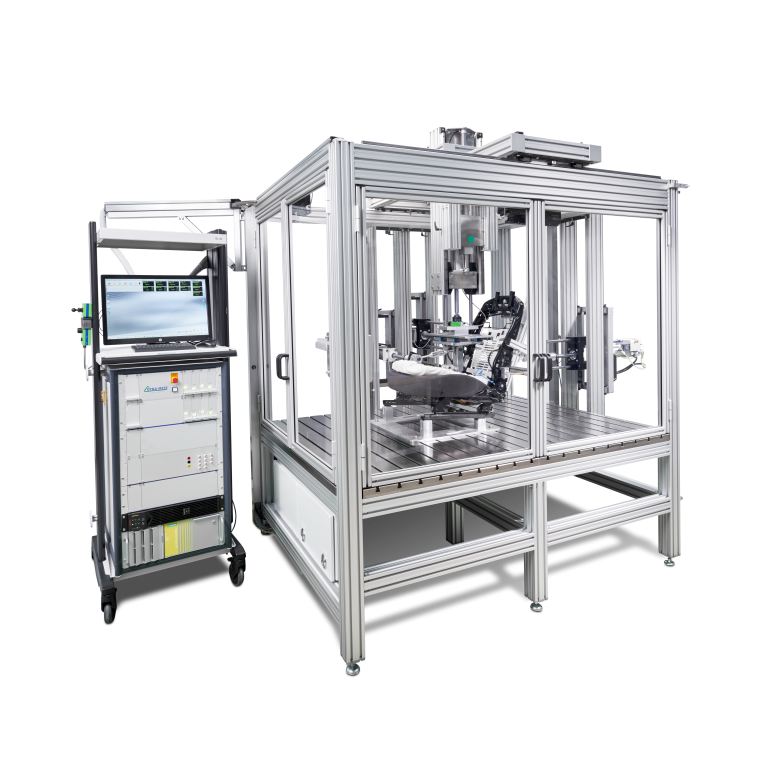

DYNA-FaSi: Driving simulation seats

Driving simulation test rig for testing vehicle seats in fatigue and endurance tests as well as static tests.

DYNA-EVP: Ehra Tester

DYNA-MESS Ehra tester for operating load tests on car seats.

DYNA-AFT

DYNA-MESS has developed the DYNA-AFT (Automated Foam Tester) testing machine for foam testing in accordance with ISO 2439, ISO 3386 and ISO 3385.

Play and stiffness test rig

DYNA-MESS test stand for measuring the play and stiffness of seats.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems