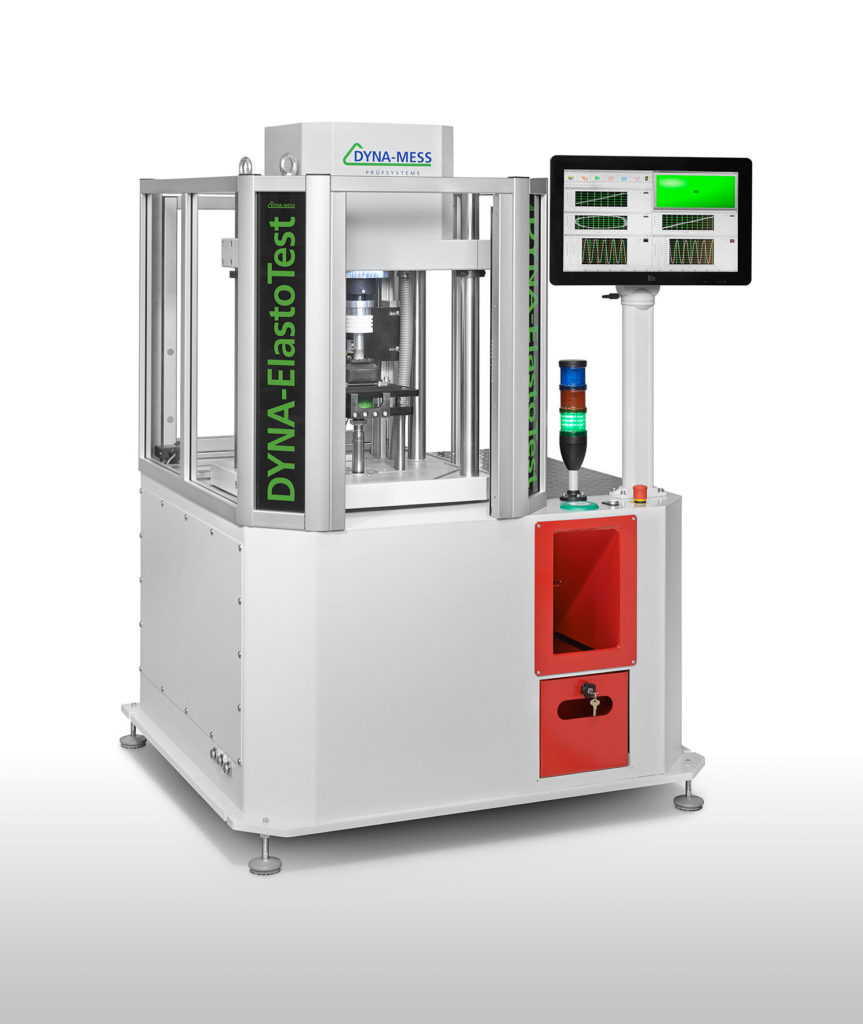

DYNA-AST

DYNA-AST: Arc Spring Tester

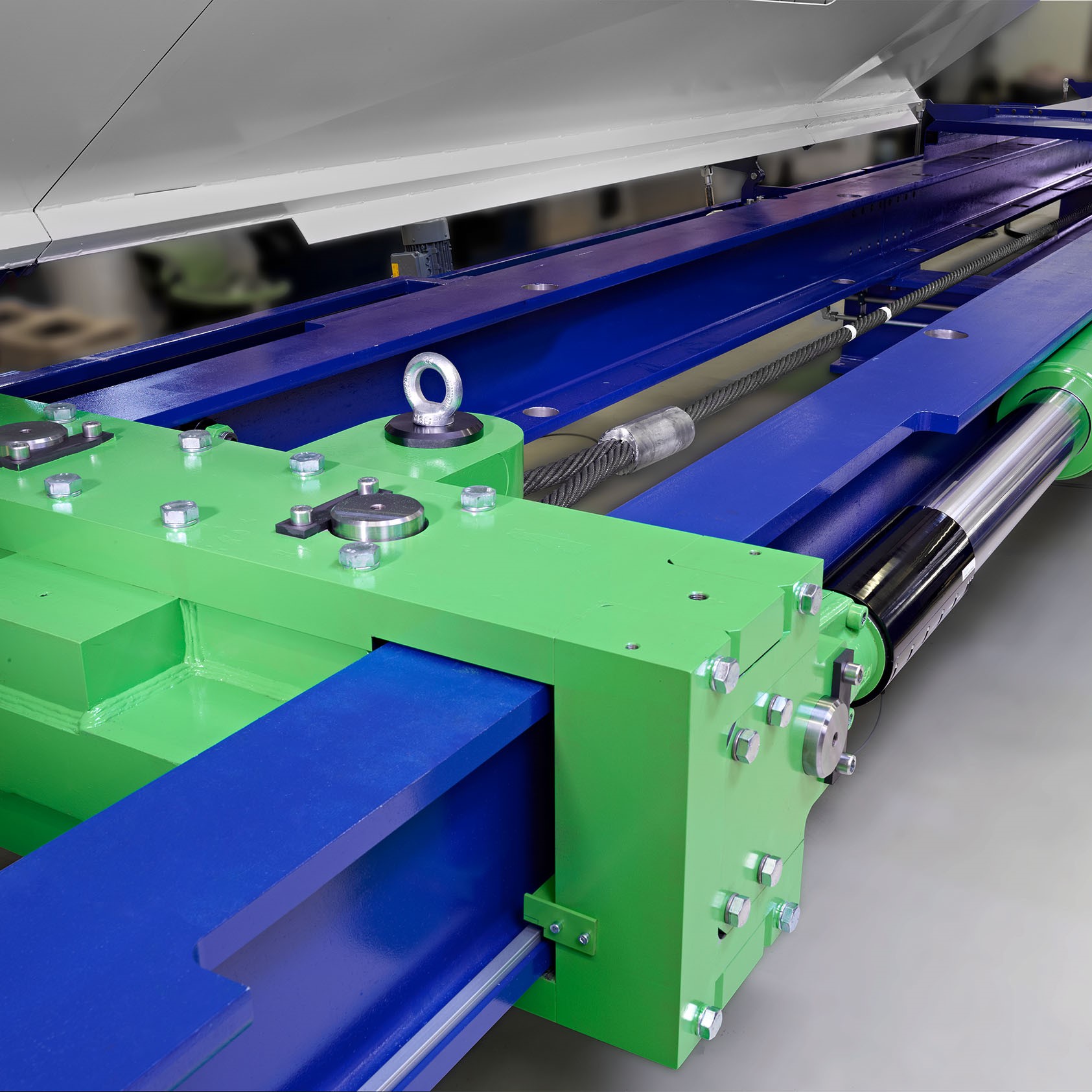

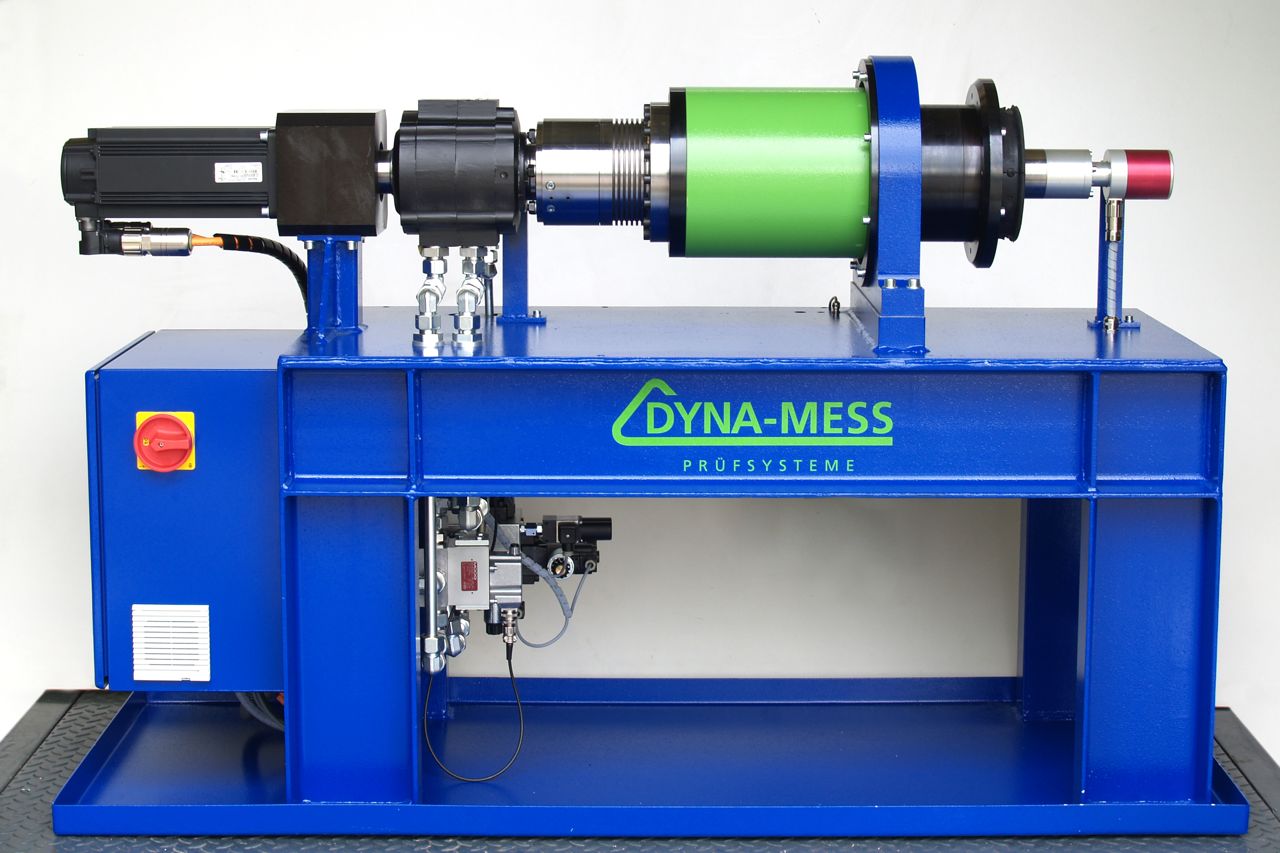

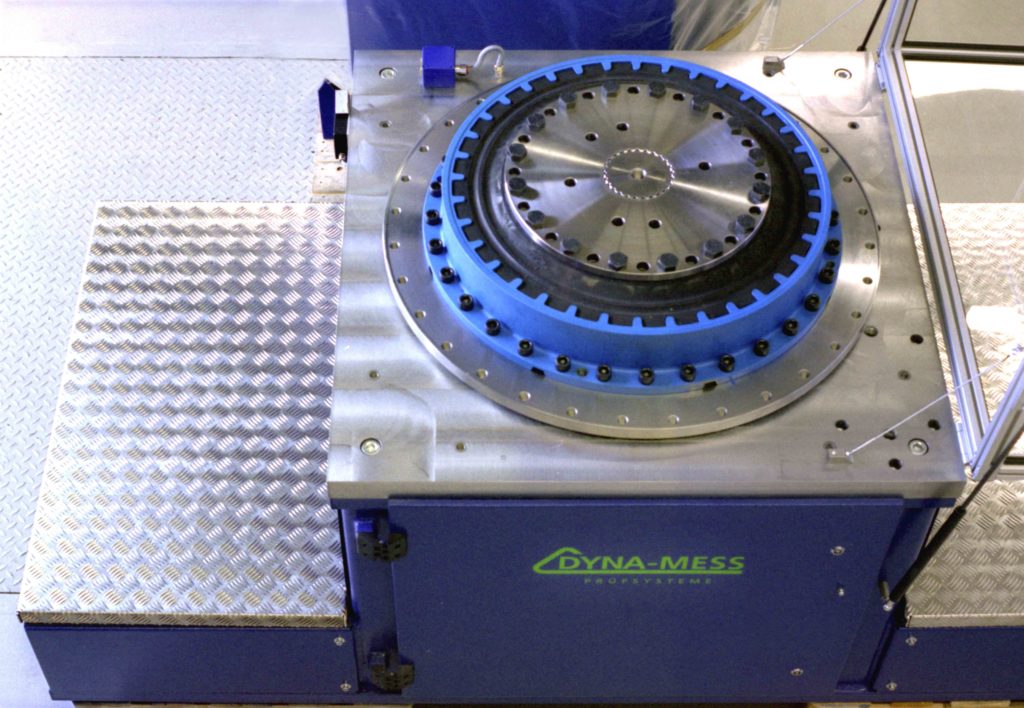

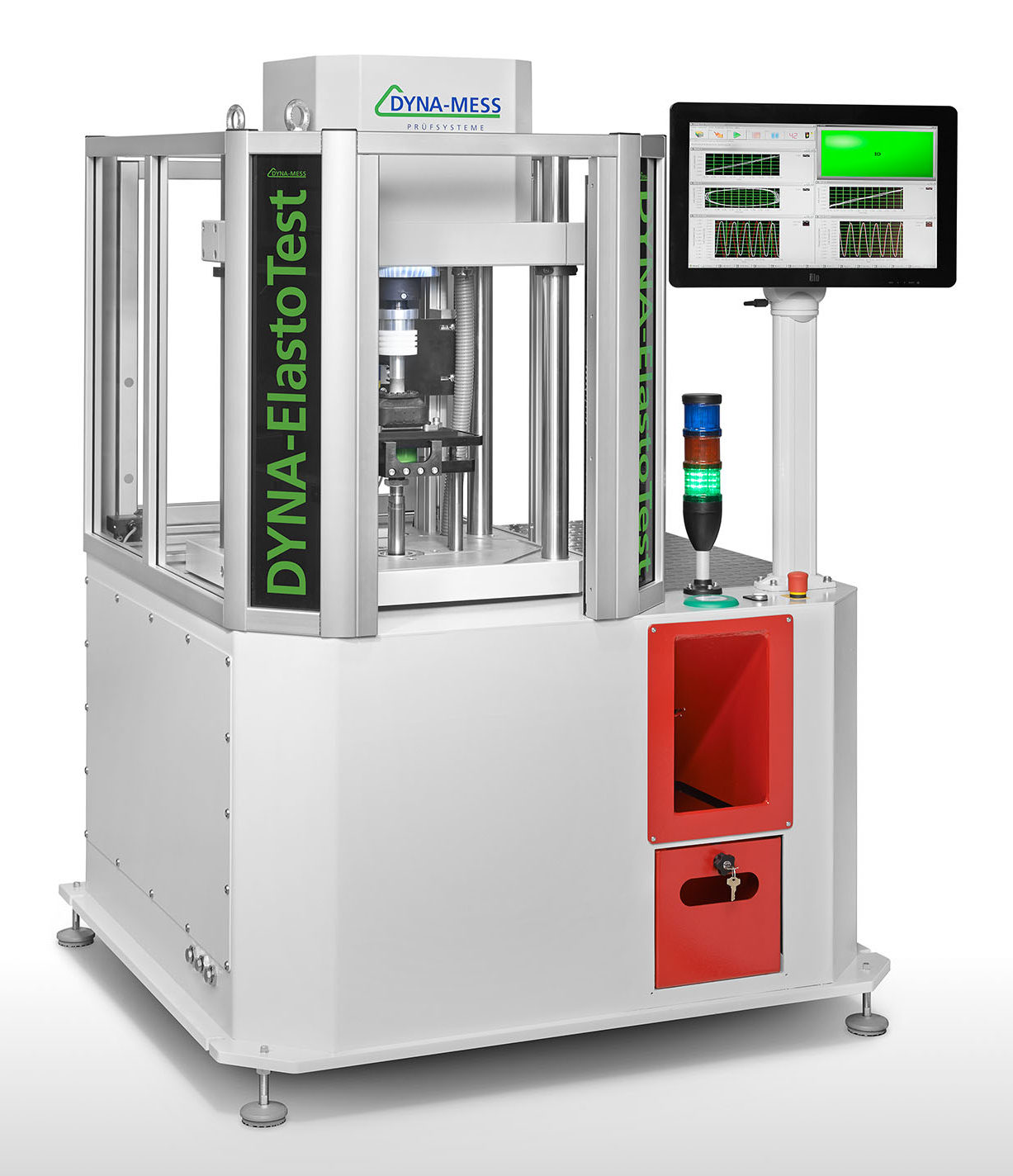

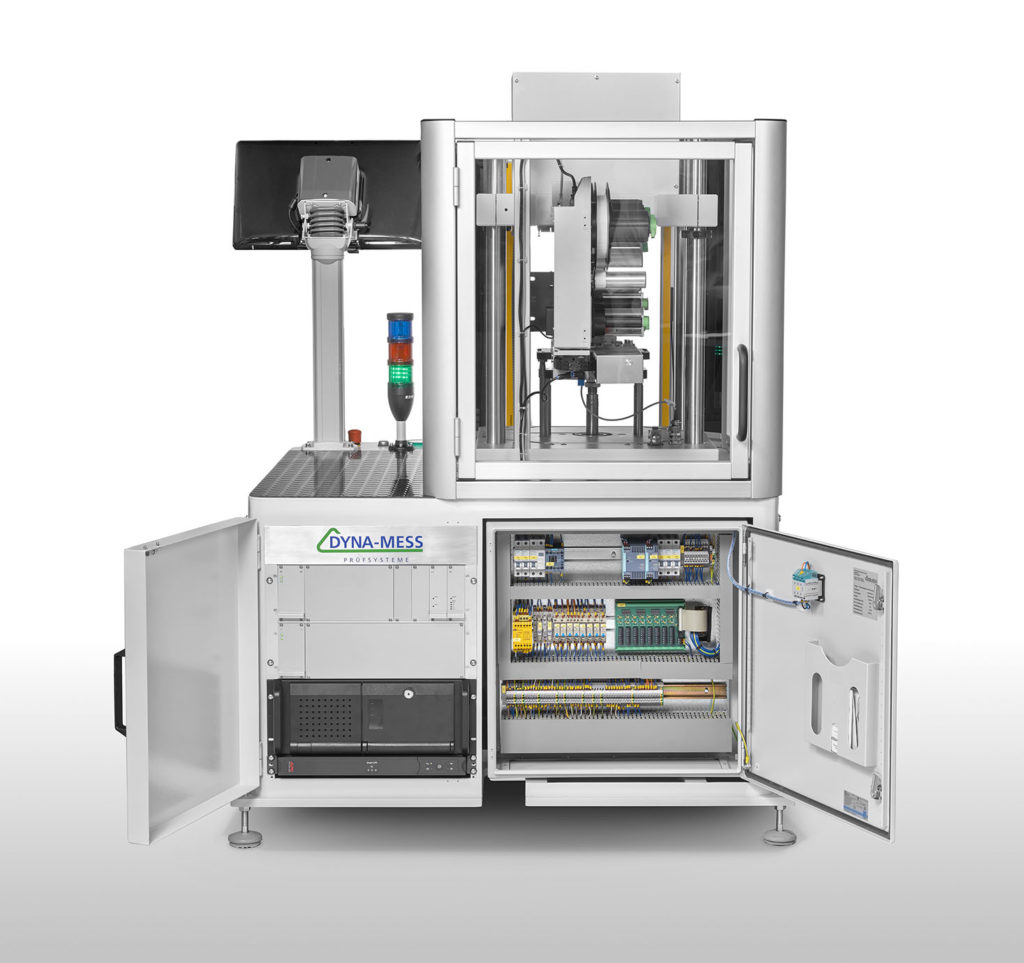

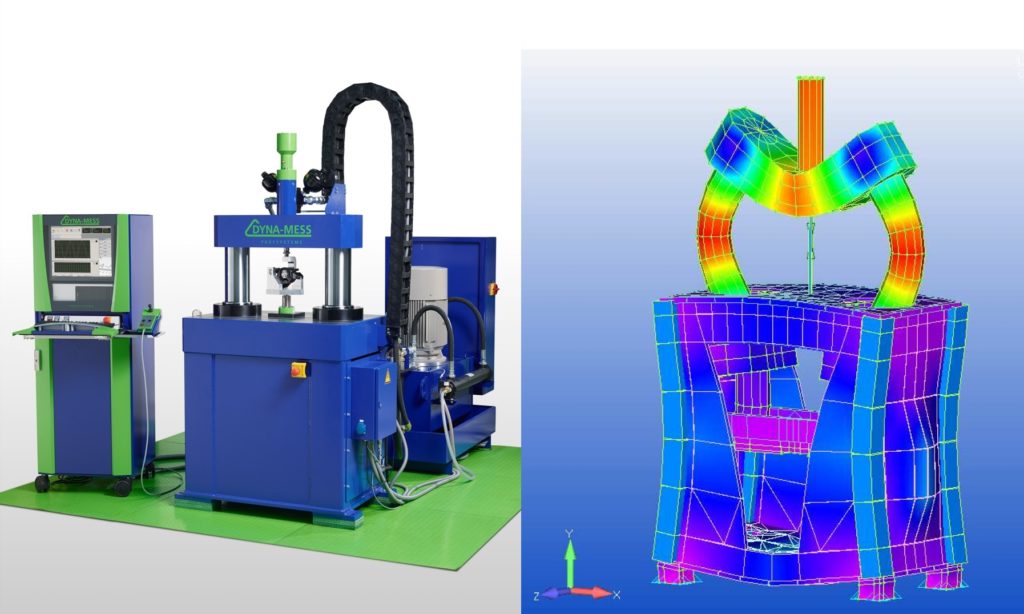

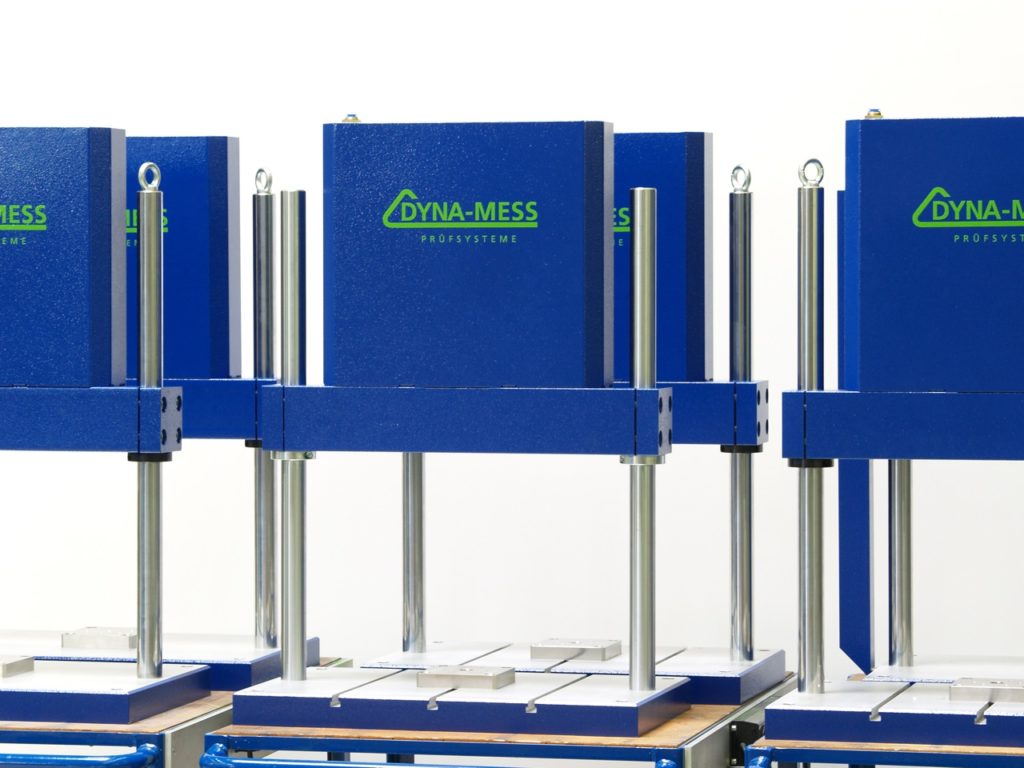

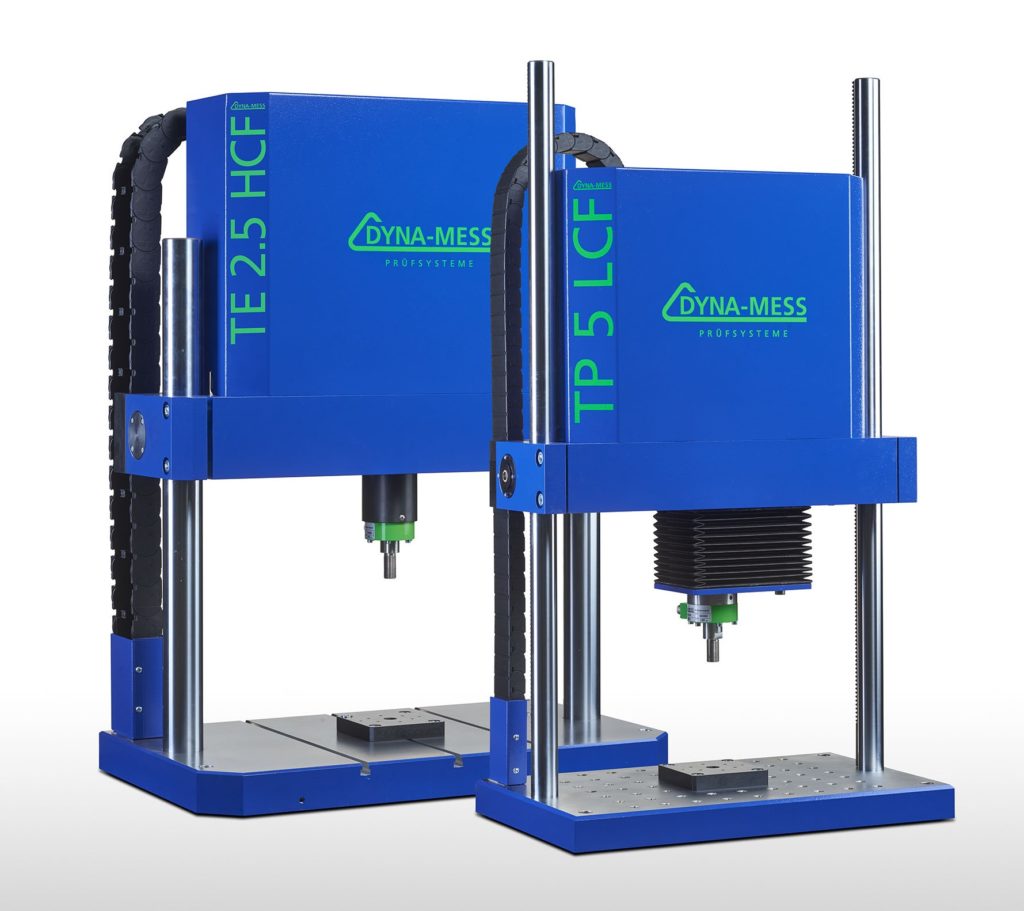

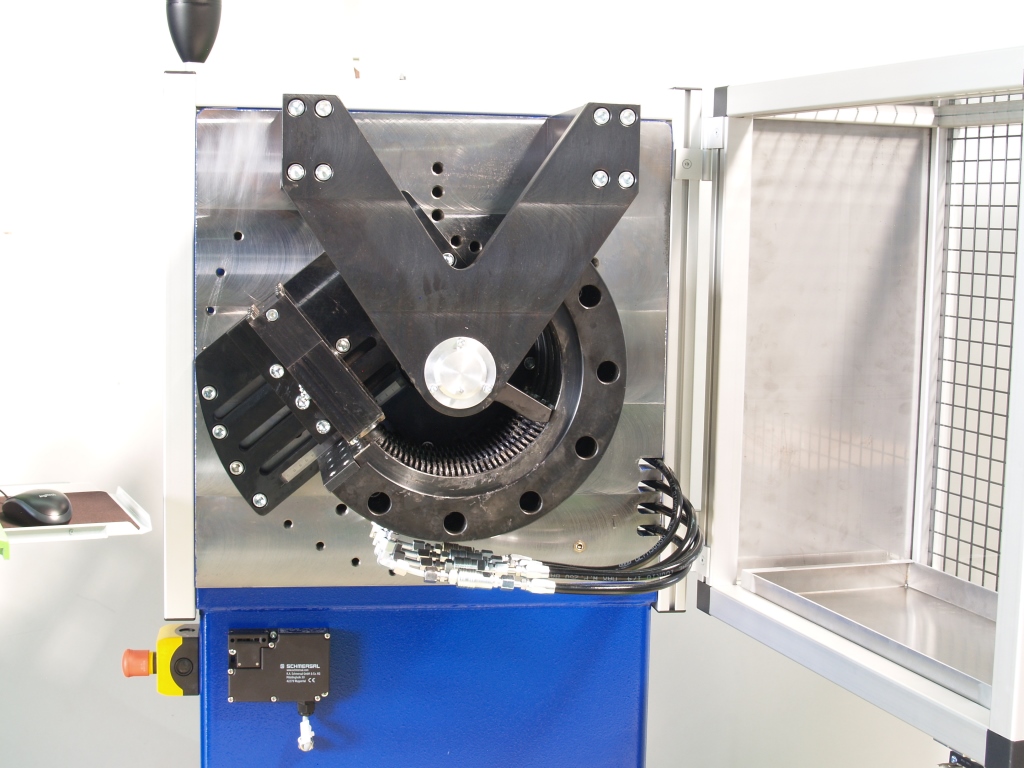

DYNA-MESS has developed the DYNA-AST (Arc Spring Tester) testing machine for the simultaneous testing of several arc springs.

We are DYNA-MESS. Test Systems.

Description

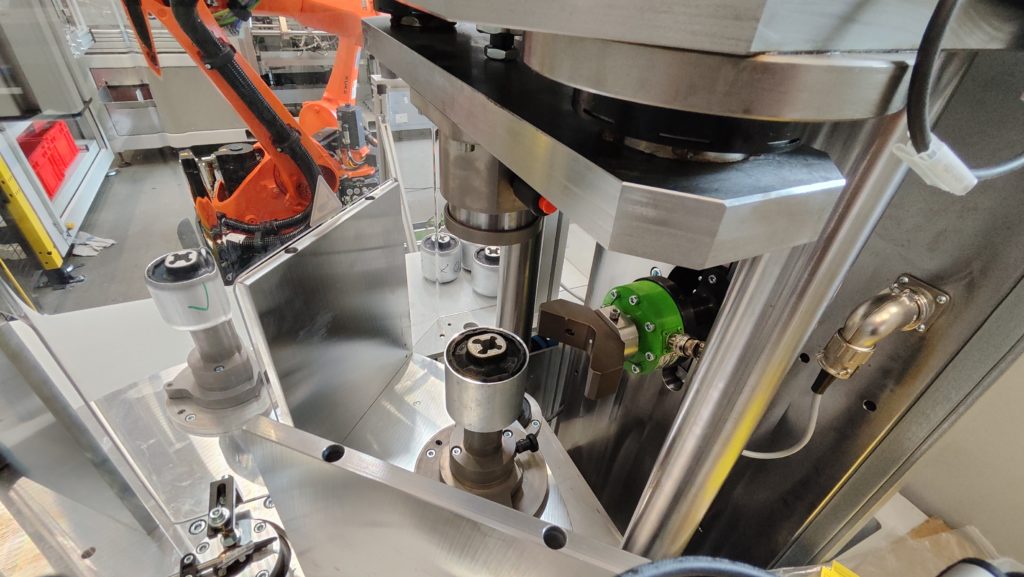

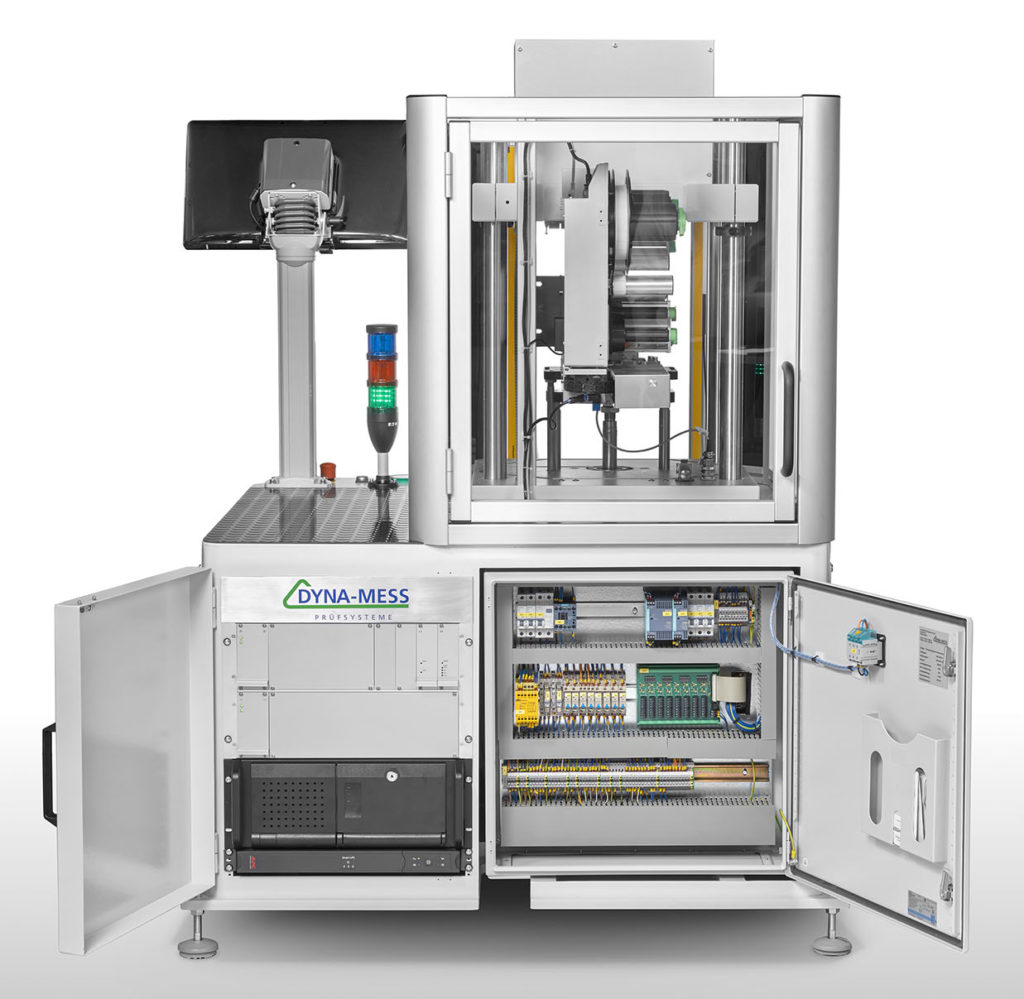

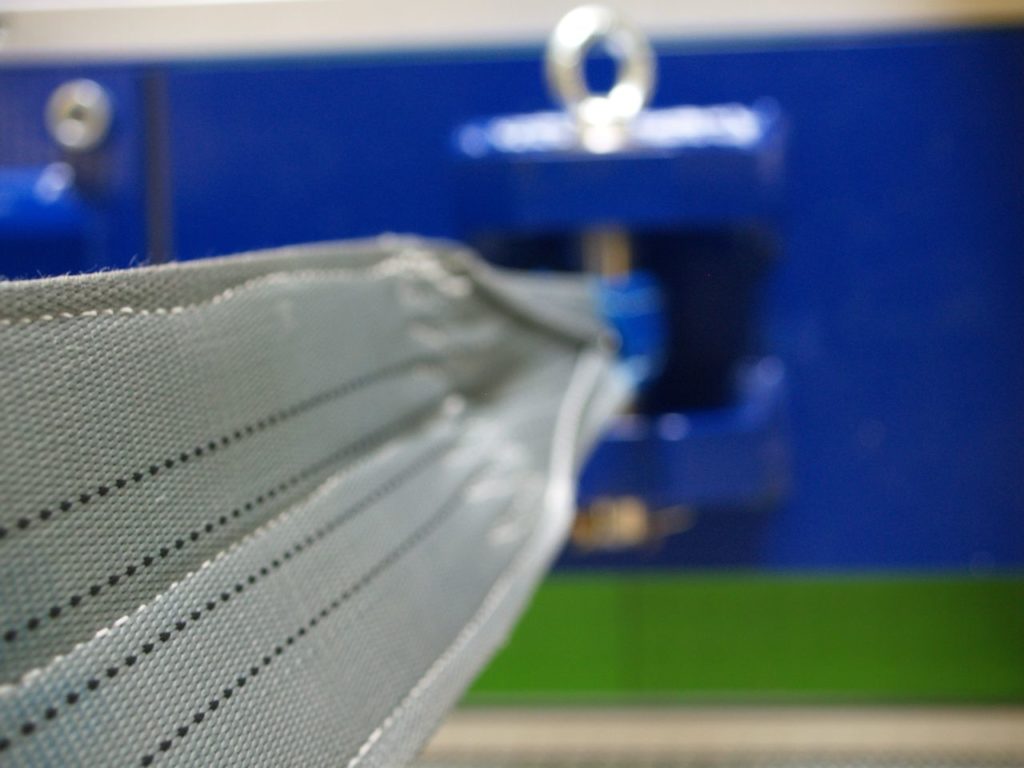

- Simultaneous testing of up to 4 springs

- Torque measurement: Precision measurement for dynamic testing

- Contactless angle measurement

- Temperature measurement

Software module “Fatigue testing on arc springs”

- Dynamic loading of the springs on block

- Dynamic tests in angle or torque control

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems