Dental

Dental

Für Kausimulation und Standardprüfungen nach ISO 14801 an Dentalimplantaten sowie für die Prüfung von Dentalwerkstoffen und kieferorthopädischen Elementen bietet DYNA-MESS Prüfmaschinen an.

Wir sind DYNA-MESS. Prüfsysteme.

Prüfungen

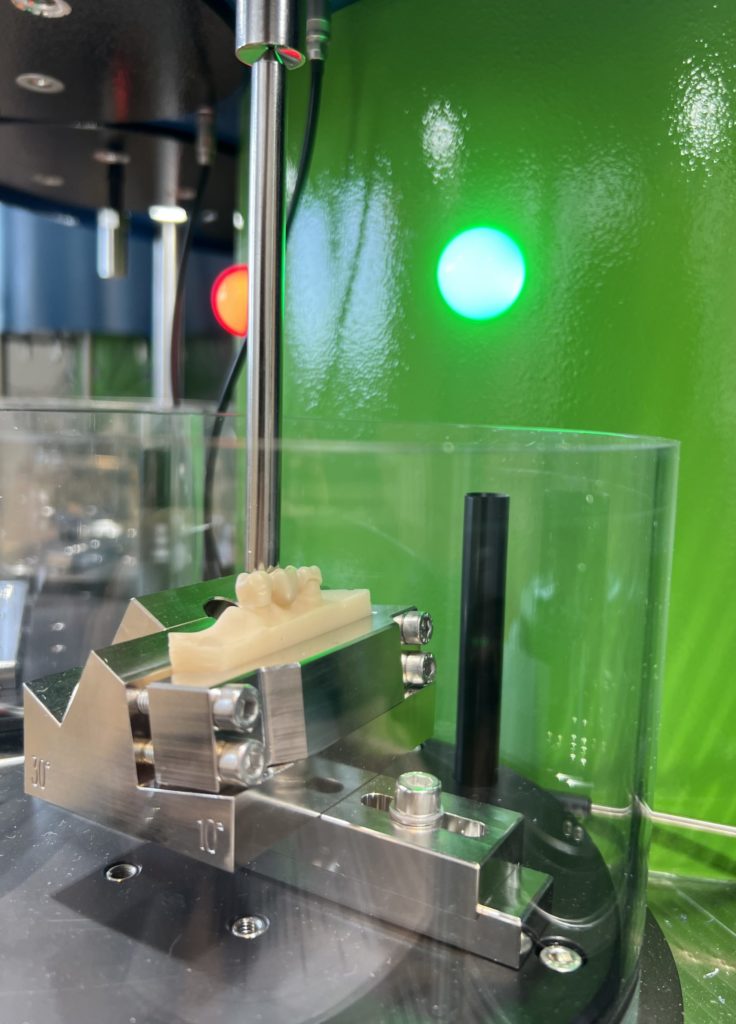

Dynamische Ermüdungsprüfung für enossale dentale Implantate (DIN EN ISO 14801)

Die ISO 14801 „Zahnheilkunde – Implantate – Dynamische Ermüdungsprüfung für enossale dentale Implantate“ beschreibt den Versuchsaufbau, die Versuchsdurchführung und -auswertung für einpfostige enossal getragene Implantate. Dabei kann es sich sowohl um Titan-Implantate als auch um Vollkeramik-Implantate handeln.

Prüfung von Dentalwerkstoffen

Die Prüfung von Dentalwerkstoffen erfolgt sowohl an standardisierten Materialproben als auch an ausgeführten Prothesen. Servopneumatische und servoelektrische Prüfmaschinen von DYNA-MESS werden dafür seit 1992 erfolgreich eingesetzt. Ausgehend vom universitären Forschungsbereich nutzen heute auch die führenden Hersteller von Dentalwerkstoffen und -implantaten DYNA-MESS Prüfmaschinen zur Ermittlung der Dauerfestigkeit ihrer Produkte.

Zahnärztliche Restaurationen

Eine Vielzahl von Bauteilen zur zahnärztlichen Restauration, wie zum Beispiel Brücken, werden auf DYNA-MESS Prüfsystemen geprüft.

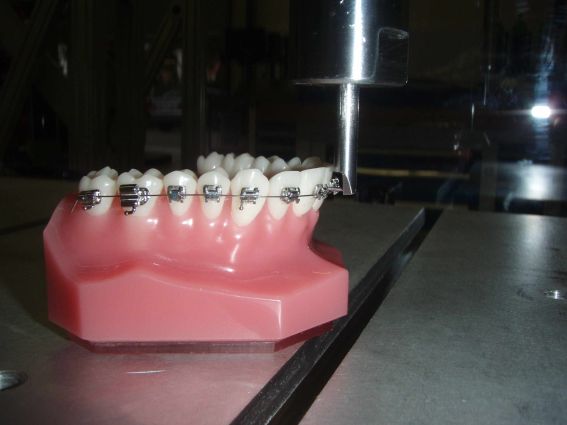

Kieferorthopädische Elemente

Neben quasi-statischen Versuchen zur Ermittlung der Scherfestigkeit von Befestigungselementen für kieferorthopädische Bögen und Zugversuchen an kieferorthopädischen Drähten lassen sich mit servopneumatsichen oder servoelektrischen Tischprüfmaschinen Dauerschwingversuche an „klassischen“ Zahnklammern, Brackets und lingualen Zahnspangen durchführen.

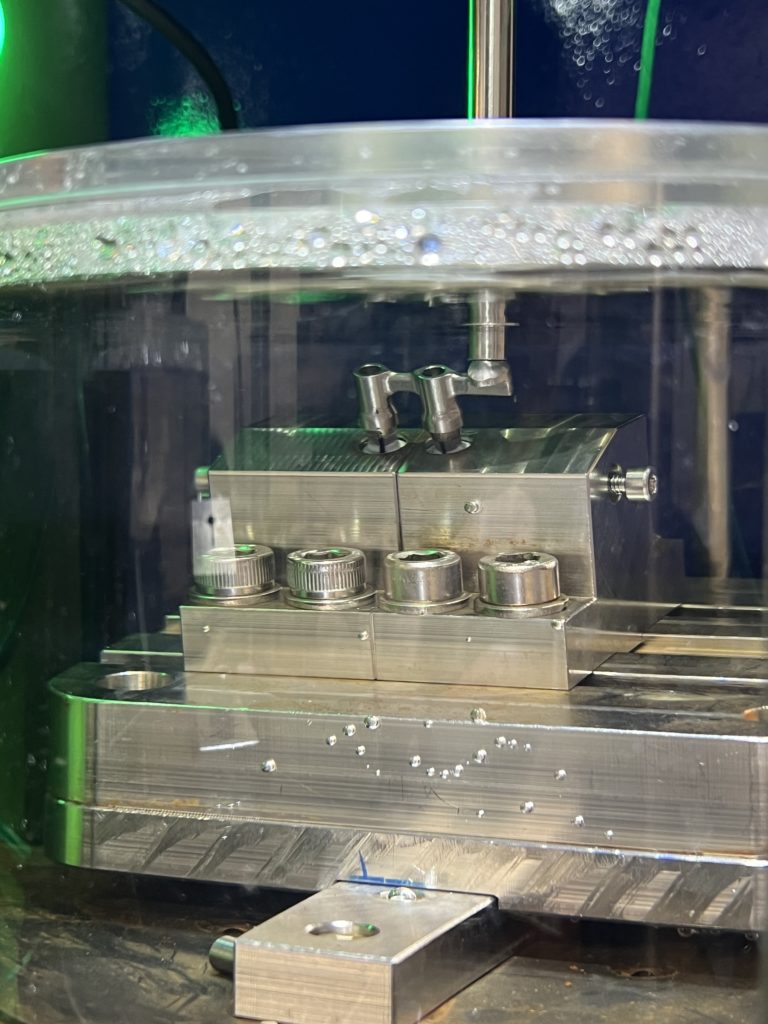

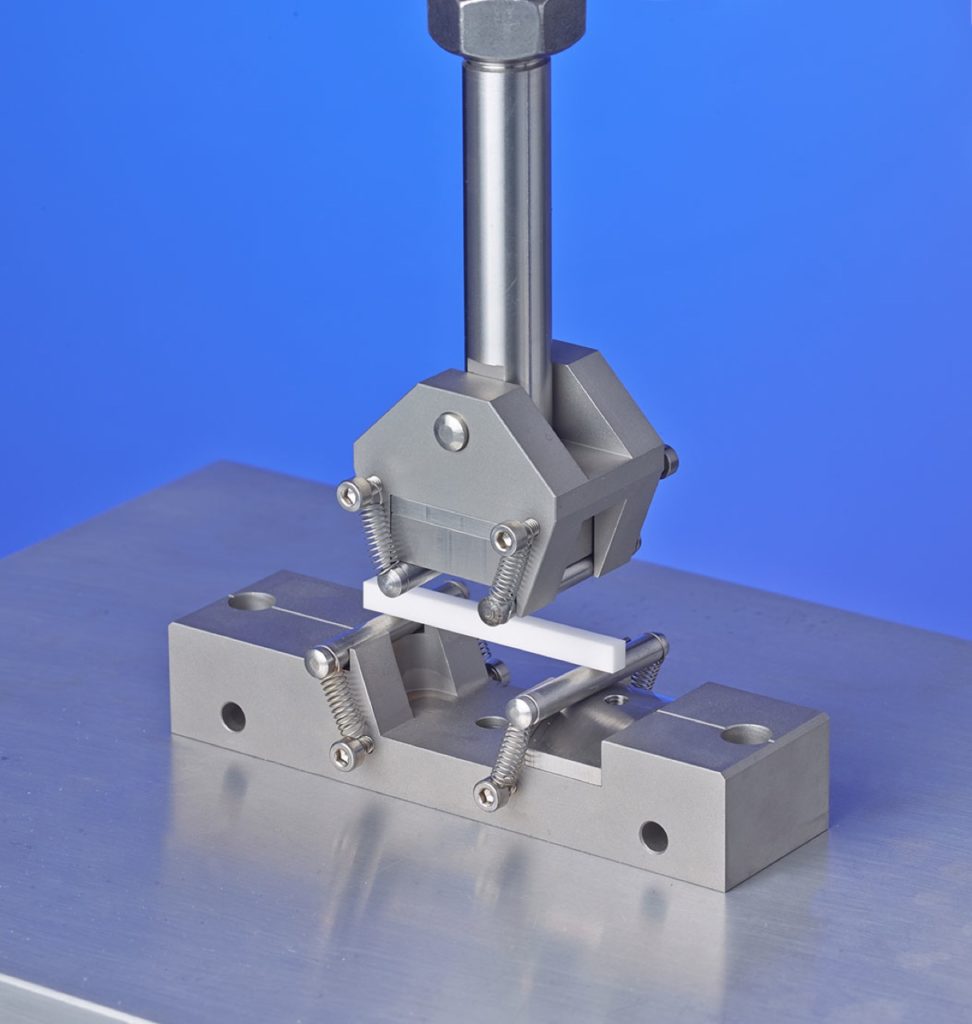

Zubehör für normgerechte Prüfungen

Für normgerechte Prüfungen sind sowohl entsprechende Einspannmittel als auch Adapter zur Lasteinleitung verfügbar, die eine querkraftfreie Belastung des diagonal eingespannten Implantats ermöglichen. Zusätzlich sind entsprechende Becken mit Medienaufbereitung und diverse Zubehöraufnahmen erhältlich, die weitere Prüfungen (Zugversuche, Biegeprüfungen,…) ermöglichen.

Prüfstempel

Für die Prüfung von Zahn- und Brückenimplantaten bieten wir zum Beispiel einen doppelseitigen Probenhalter mit einem Spannwinkel von 10° an.

PASSENDE PRODUKTE

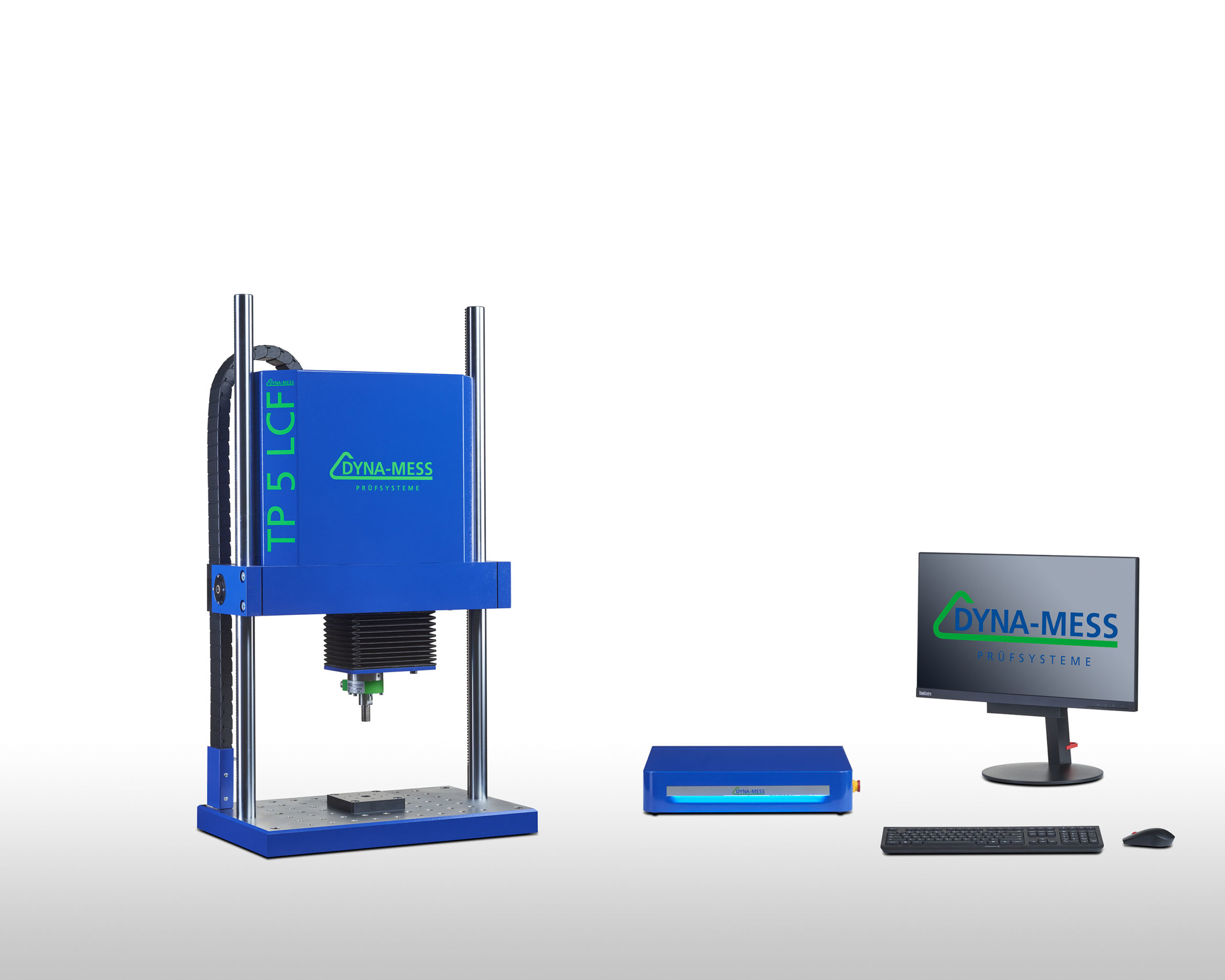

DYNAdent

Für Prüfungen nach ISO 14801 an Dentalimplantaten bietet DYNA-MESS perfekt abgestimmte Maschinen an.

UNSERE SERVICES FÜR SIE

Kalibrierung

Prüfsysteme justieren

Präzise kalibriert für zuverlässige Messergebnisse und Qualitätssicherung

Wartung

Prüfsysteme pflegen

Professionelle Wartung für optimale Leistung und lange Lebensdauer

Reparatur

Prüfsysteme instandsetzen

Reparaturen für reibungslosen Betrieb und optimale Leistung

Modernisierung

Prüfsysteme immer aktuell

Moderne Technologie für verbesserte Leistung und Genauigkeit

Zubehör

Prüfsysteme aufrüsten

Erweiterte Funktionen und Technologien komplettieren Prüfmaschinen

Schulungen

Prüfsysteme verstehen

Anwender- und Themenschulungen rund um DYNA-MESS Prüfsysteme