Endoprosthetics

Endoprosthetics

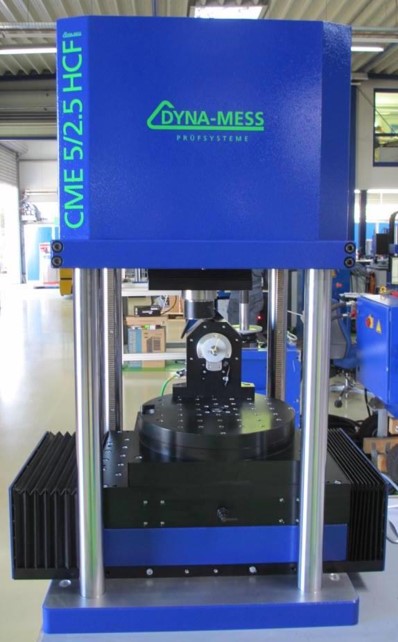

A wide range of mechanical tests on endoprostheses can be performed with servo-pneumatically and servo-electrically operated universal testing machines from DYNA-MESS. DYNA-MESS has developed user-friendly special test rigs to fulfill special norms and standards for fatigue and wear tests.

We are DYNA-MESS. Test Systems.

Hip

ISO 7206-4

“Surgical implants – Tension torsion testing of artificial hip joints ISO 7206 Partial and total hip replacements – Part 4: Fatigue testing of prosthetic stems”

ISO 7206-6

“Surgical implants – Partial and total hip replacement – Part 6: Determination of the toughness properties of the caput and collum of the femoral stem”

ISO 7206-8

“Surgical implants – Partial and total hip replacement – Part 8: Loading capacity of prosthetic stems with torsional stress”

ISO 7206-10

“Surgical implants – Partial and total hip replacements – Part 10: Determination of resistance to static loading of modular prosthetic heads”

ISO 7206-12

“Surgical implants – Partial and total hip joint replacement – Part 12: Deformation testing of acetabular cups”

ISO 14242-1

“Surgical implants – Wear behaviour of total hip replacements – Part 1: Load and motion parameters for wear testing machines and associated test conditions”

Tests on hip endoprostheses are performed both as fatigue tests on the stems and as combined compression/torsion tests with ball cups. DYNA-MESS offers the DYNA-EndoWear machine especially for testing hip implants.

The DYNA-MESS testing software ensures compliance with the load values and – in the case of multi-axial loads – the correct temporal relationship between the individual loads.

Knee

ISO 14879-1

“Surgical implants – Total knee endoprostheses – Part 1: Determination of the loading behaviour of tibial pads for knee joint replacement”

ISO 14243-1

“Surgical implants – Wear behaviour of total knee endoprostheses – Part 1: Load and motion parameters for load-controlled wear testing machines and associated test conditions”

ISO 14243-3

“Surgical implants – Wear behaviour of total knee endoprostheses – Part 3: Load and displacement parameters for displacement-controlled wear testing machines and corresponding environmental conditions for testing”

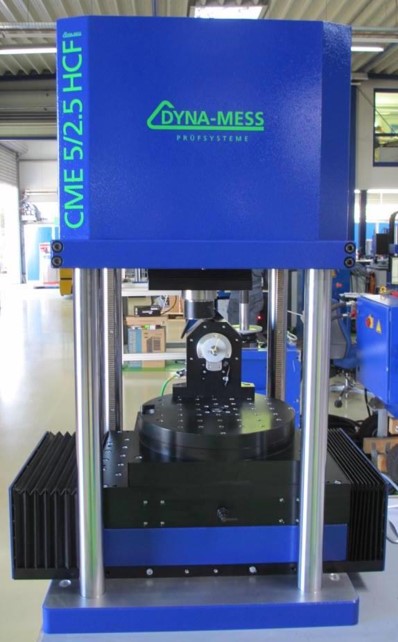

DYNA-MESS has developed the DYNA-EndoK testing machine especially for testing knee implants in accordance with the ASTM 1223 / ASTM F2722 / ASTM 2723 / ASTM F2724 / ASTM F2777 standards.

Spine

ASTM F 1717-96

Endurance test on spinal fixators. Testing of a fully assembled spinal implant via two UHMWPE vertebral replacement bodies

ASTM F 1798-97

Testing of subcomponents of a spinal implant (fixation screws,…)

ASTM F 2077-01

Testing of intervertebral bodies

Dental

Testing of dental implants

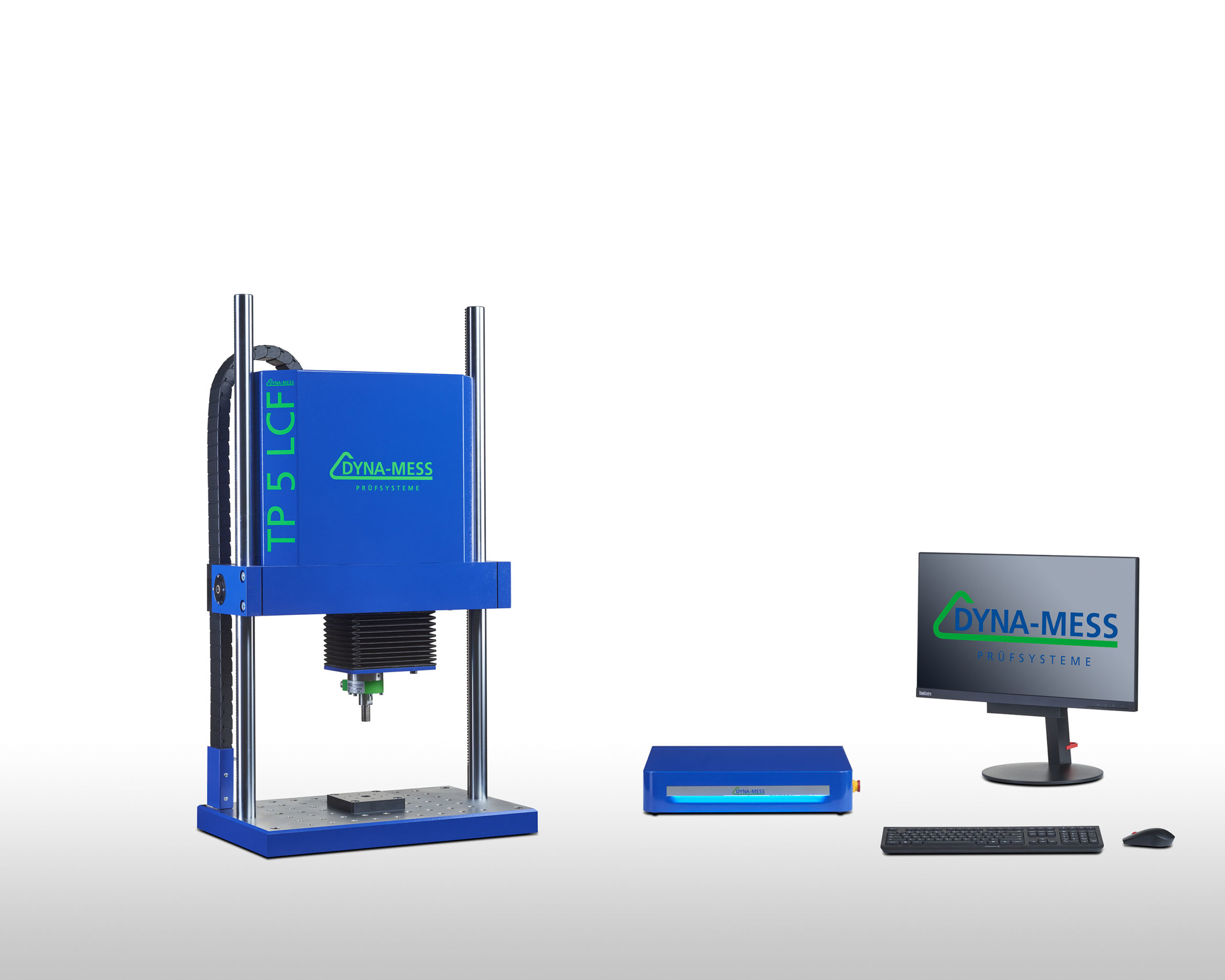

DYNA-MESS offers a perfectly customised machine for testing dental implants in accordance with ISO 14801.

Accessories

Accessories for standardised testing

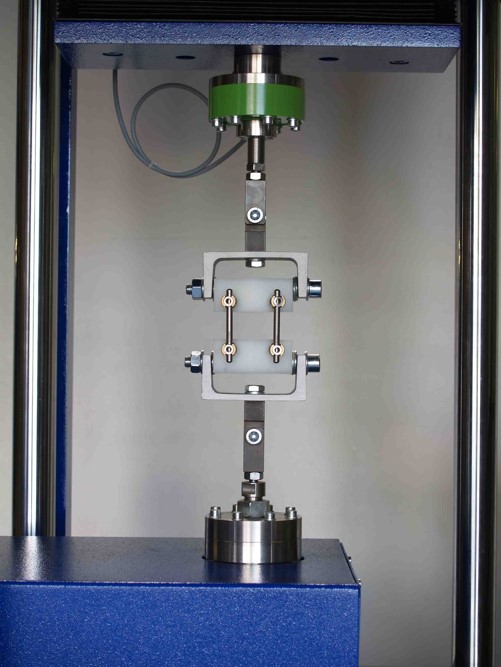

For standardised tests, both appropriate clamping devices and adapters for load application are available, which allow the prosthesis mounted at an angle to be loaded without transverse forces. In addition, corresponding basins with media preparation and various accessory holders are available to enable further tests (tensile tests, bending tests, etc.).

Bone cement

For the dynamic testing of bone cement, standardised test specimens are tested in bending tests.

Additionally, cemented implants (e.g. the stem of a hip joint in the os femoris) are dynamically loaded in order to investigate the bond between the implant and the bone.

SUITABLE PRODUCTS

DYNAdent

DYNA-MESS offers perfectly customised machines for testing dental implants in accordance with ISO 14801.

DYNA-EndoWear

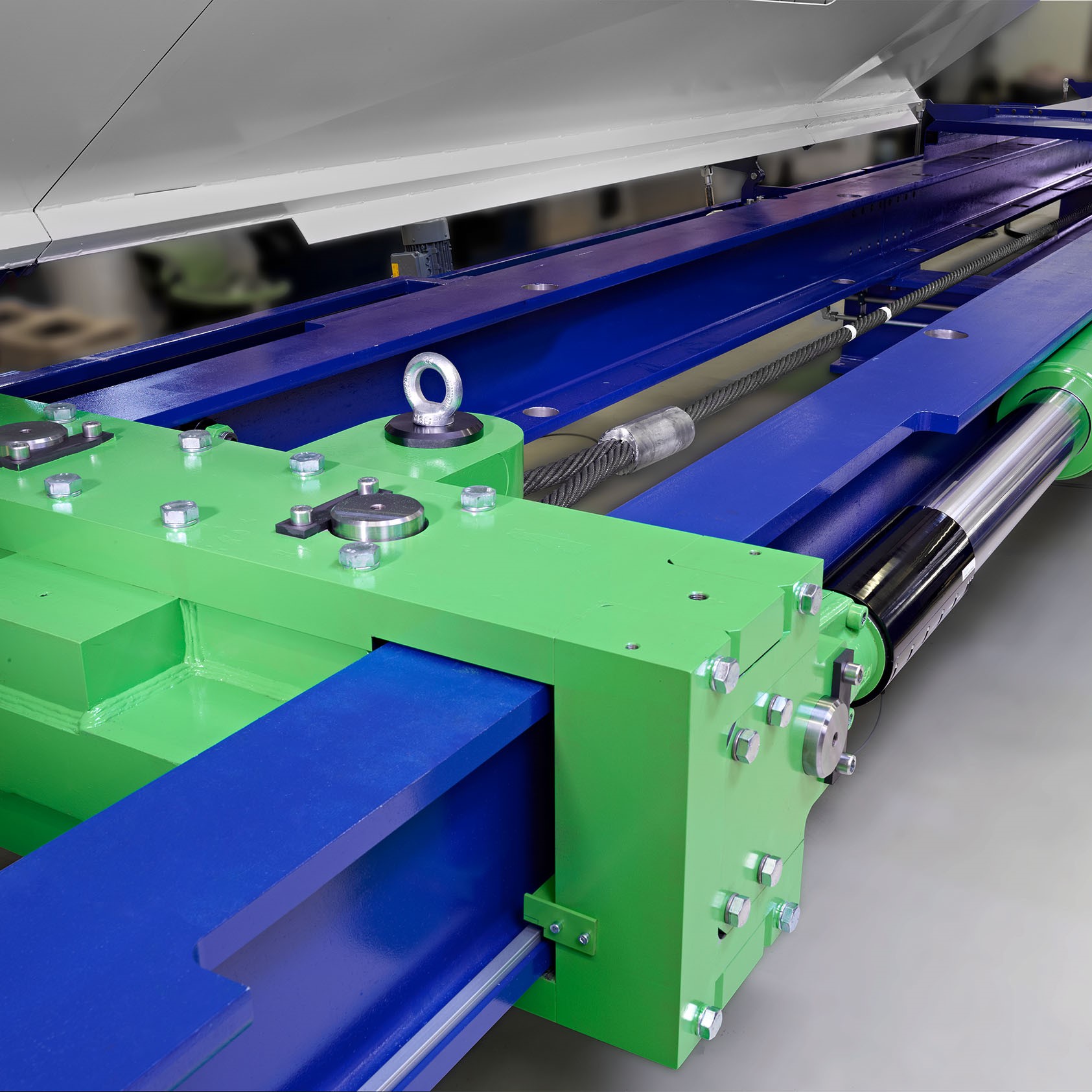

In close co-operation with universities, users and clinics, DYNA-MESS has developed the purely electrically powered wear simulator DYNA-EndoWear.

DYNA-EndoK

DYNA-MESS testing machine for fatigue tests, tensile and compression tests as well as tests according to various standards and requirements for knee joint prostheses.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems