Material testing

Material testing

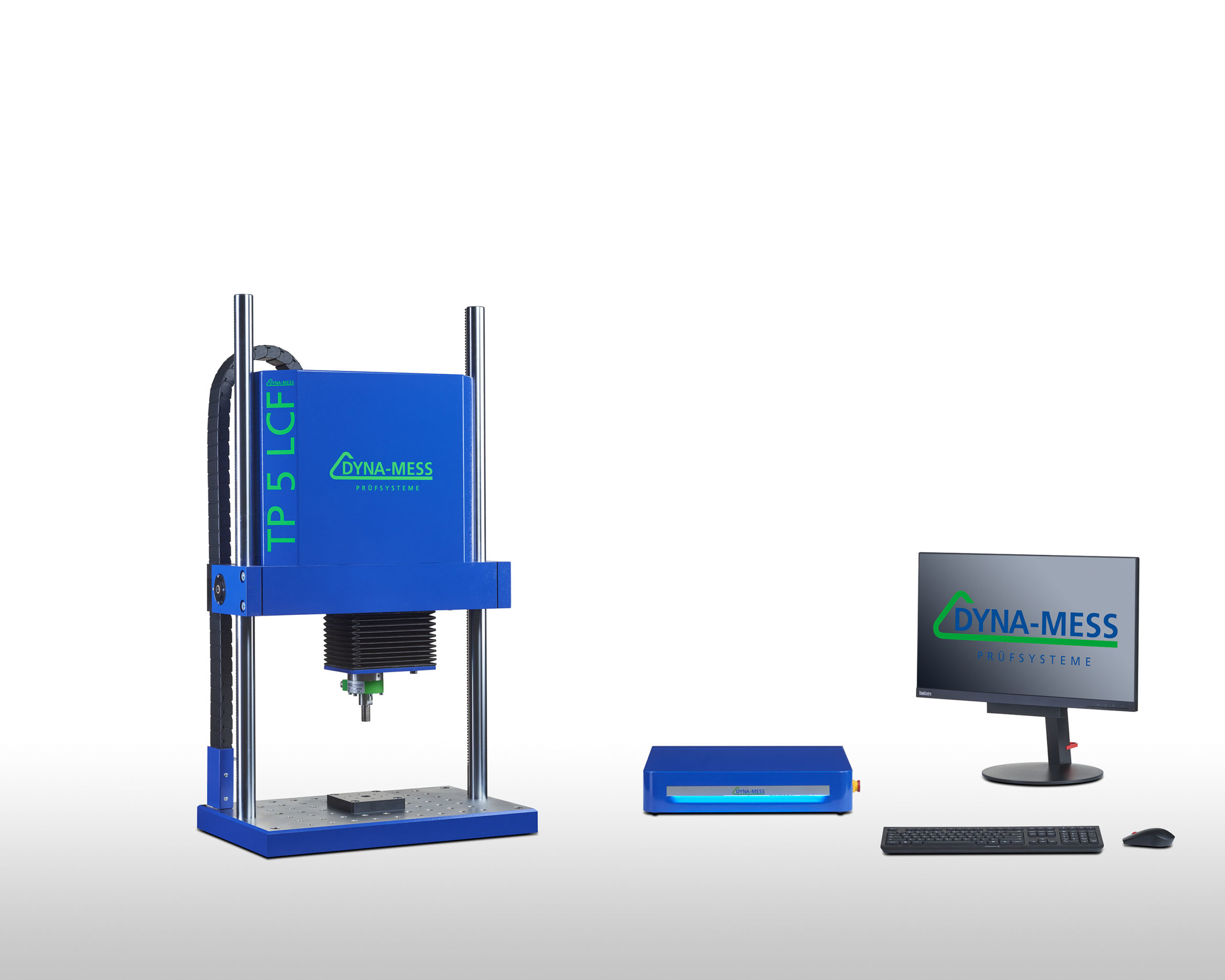

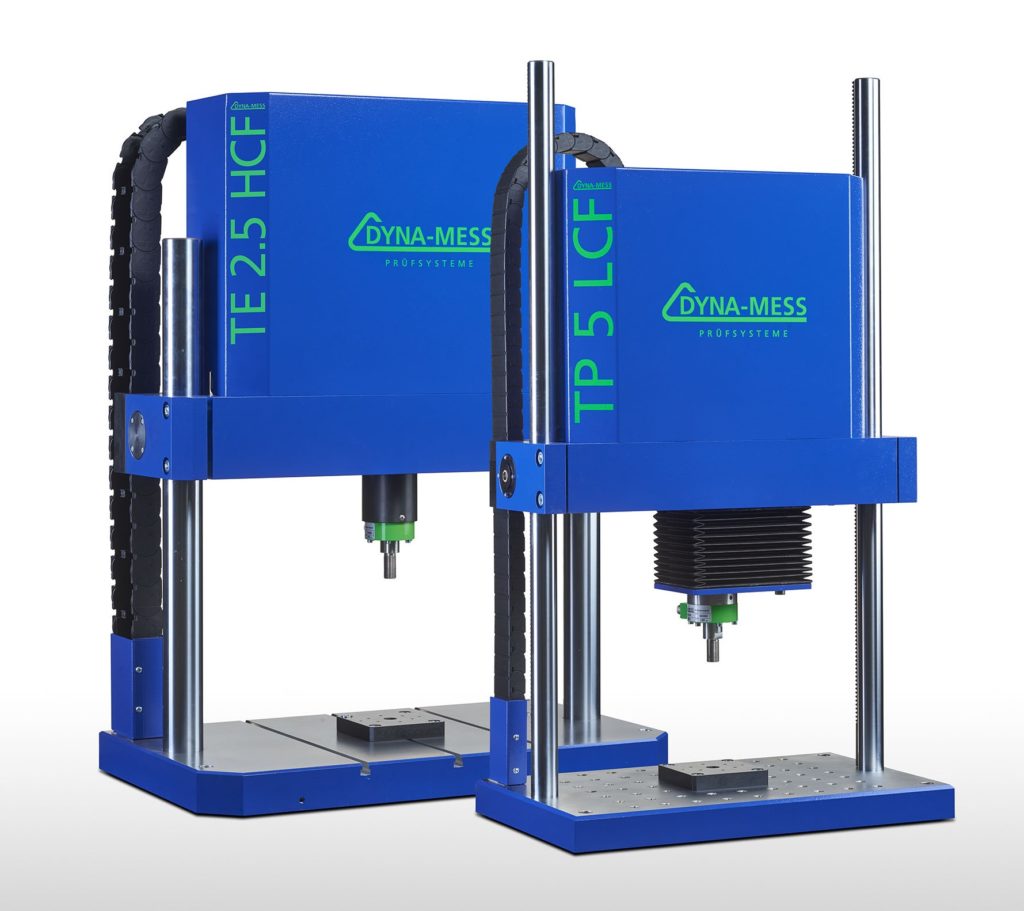

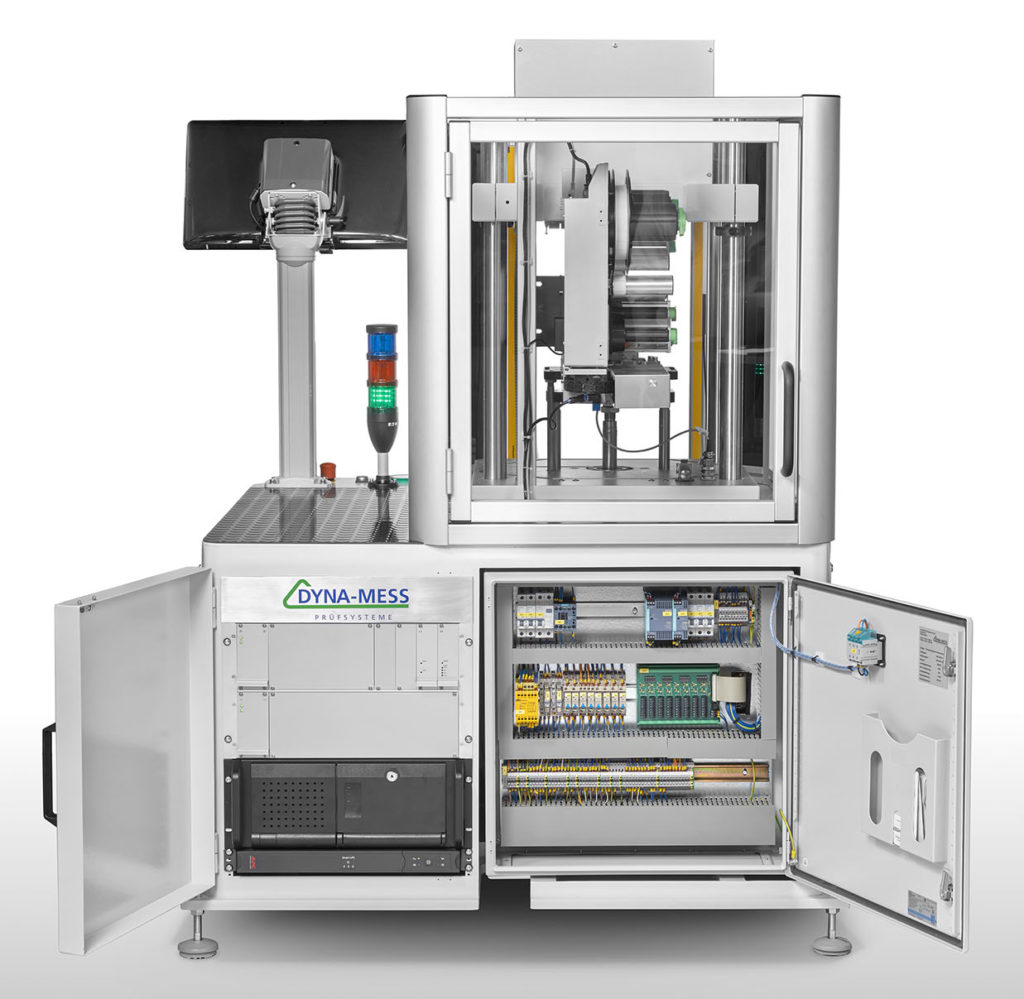

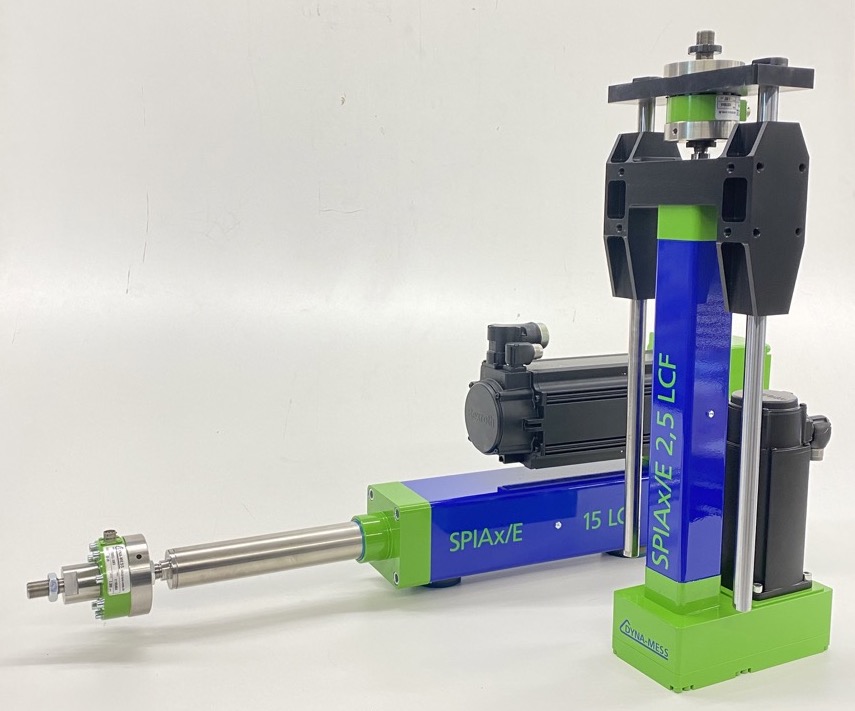

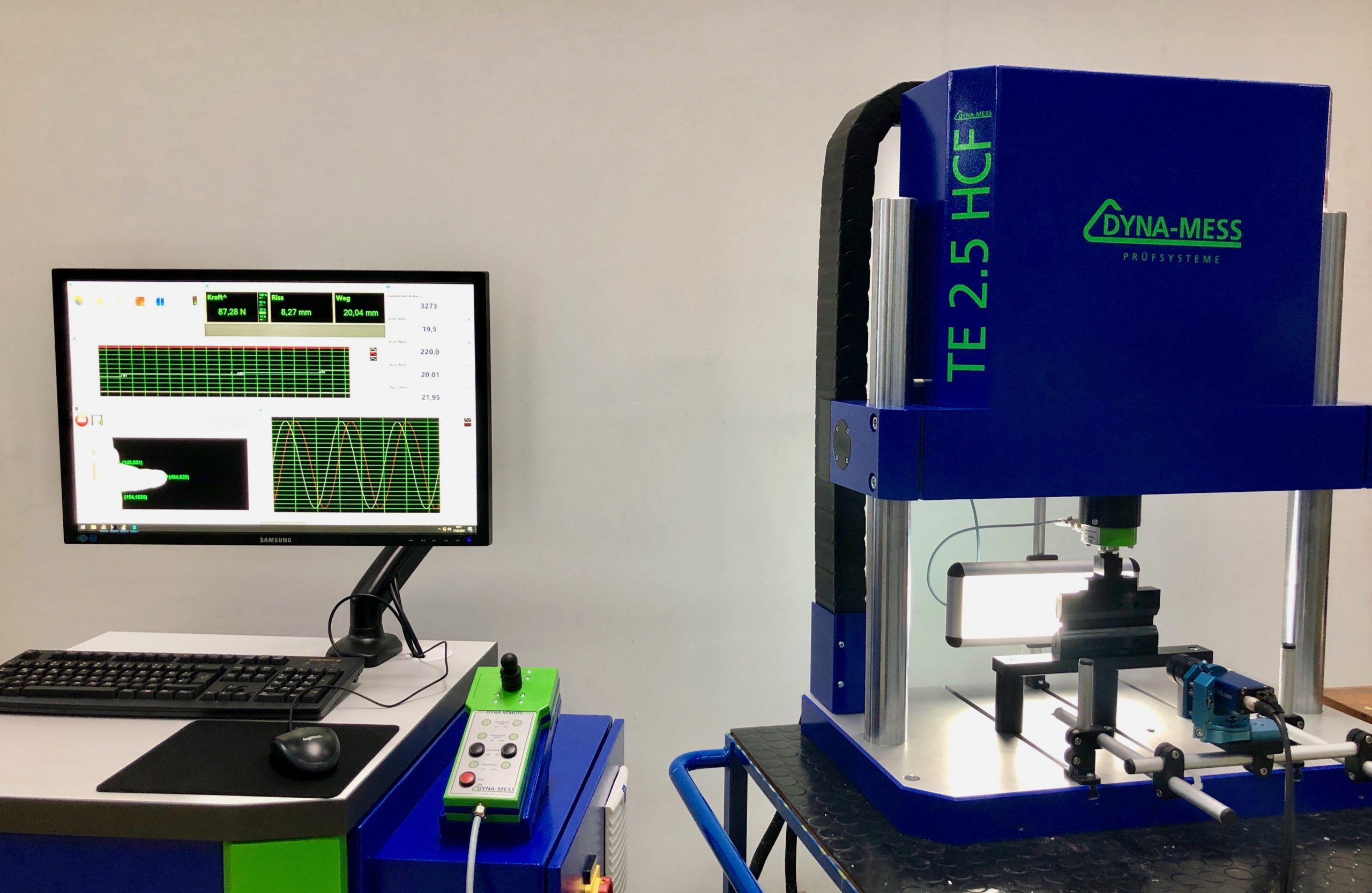

The characteristic values of materials are determined both statically and dynamically. DYNA-MESS testing machines can be used for both types of testing from a few Newtons up to the meganewton range. We are guided by global guidelines and standards as well as individual customer specifications.

We are DYNA-MESS. Test Systems.

Tests

Standardised sample forms

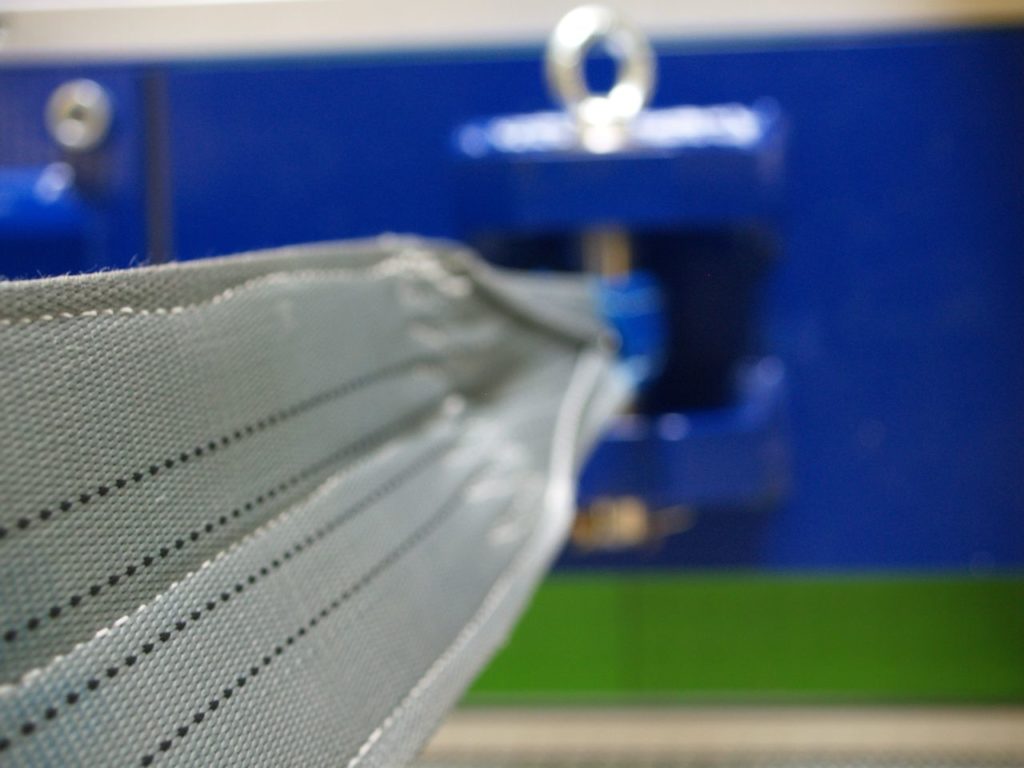

In contrast to component and part testing, materials are generally tested on standardised specimens. A classic example of this are tensile tests on metallic specimens in accordance with EN 6892.

In quasi-static tests – often referred to as “static tests” – the load is applied so slowly that dynamic effects do not play a role. Typical results of quasi-static tests are, for example

Quasi-static tests

- Tensile strength Rm

- Yield strength ReH/ReL

- E-modulus E

- Elongation at break A

- Spring stiffness C

- …

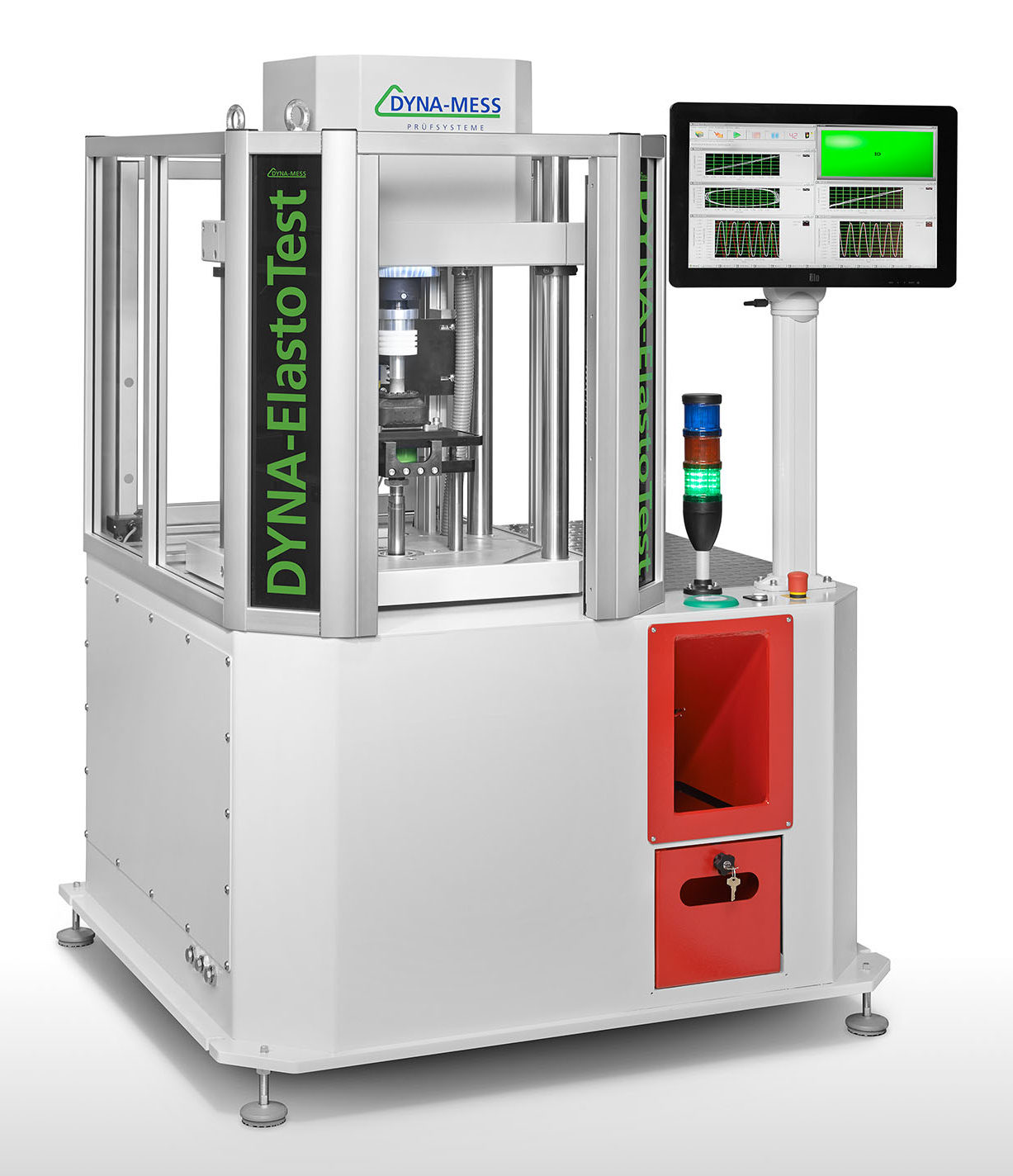

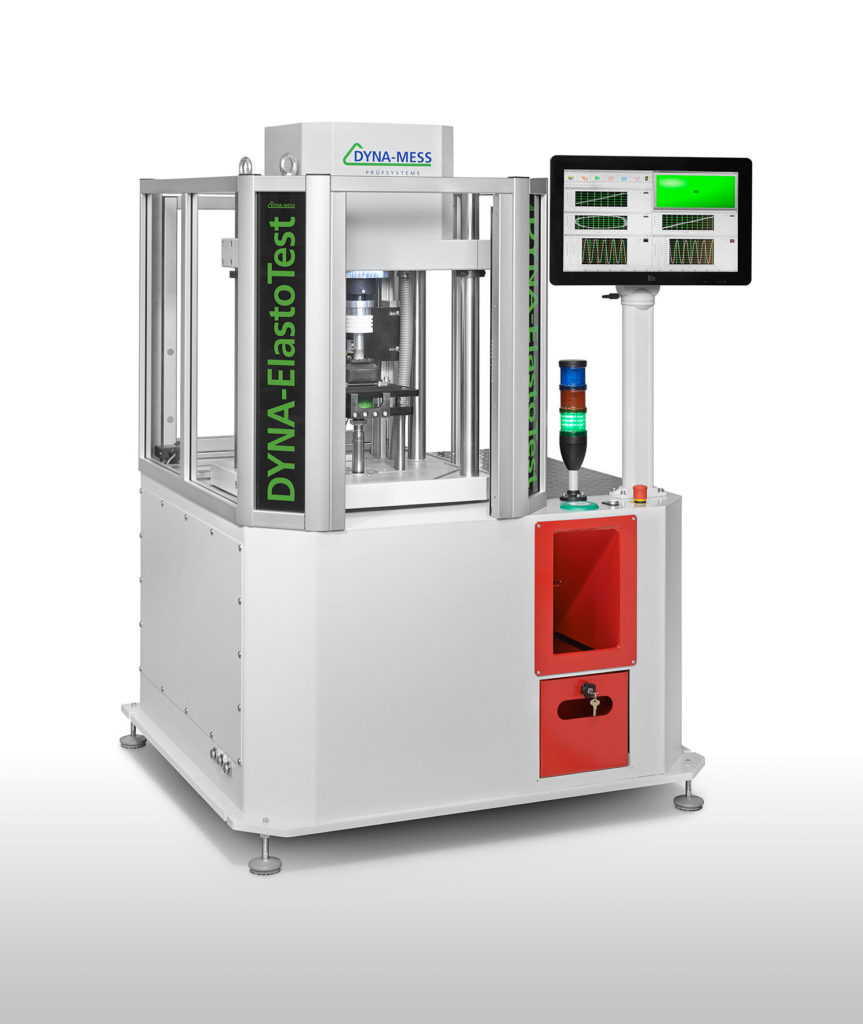

Dynamic tests

In dynamic tests, a – usually cyclical – load is applied with a corresponding test frequency. These can be threshold load tests in the tensile or compression range as well as alternating load tests with tensile and compression components.

Dynamic tests are used to determine characteristic values on the one hand and to test service life on the other. Typical dynamic characteristic values are e.g.

- Wöhler curve

- Service life

- Hysteresis curve

- Dynamic stiffness Cdyn

- Loss angle φ

- Loss work Wverl

- …

Individual testing and endurance testing

While the static and dynamic characteristic values of the materials are determined in individual tests, the long-term behaviour under dynamic load is examined as part of endurance tests. The continuous data recording of the DYNA-MESS testing software documents both the running-in effects at the start of the test and the change in the test specimen during the test period.

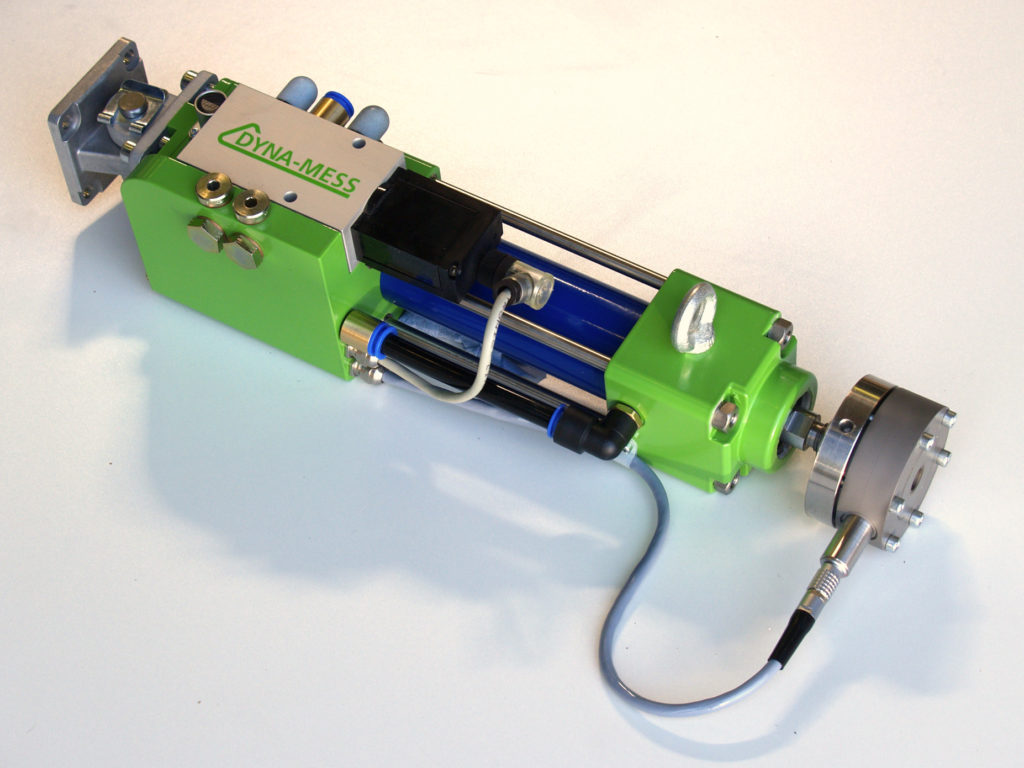

Matching accessories

In order to fulfil the requirements of the various standards, we offer additional accessories such as clamping fixtures, special and standard-compliant devices, tactile or non-contact extensometers in longitudinal and transverse direction, temperature control devices …

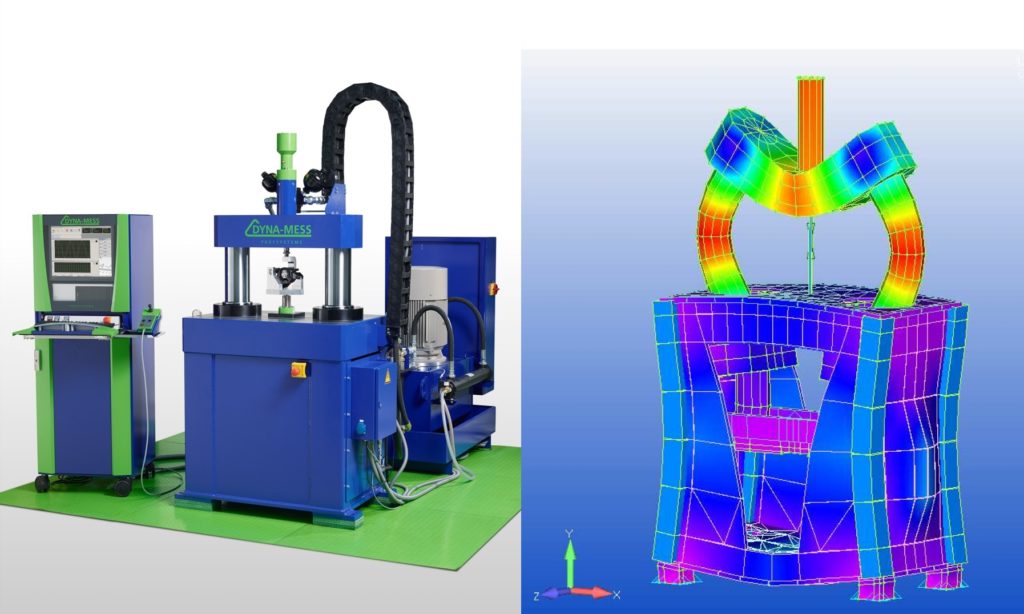

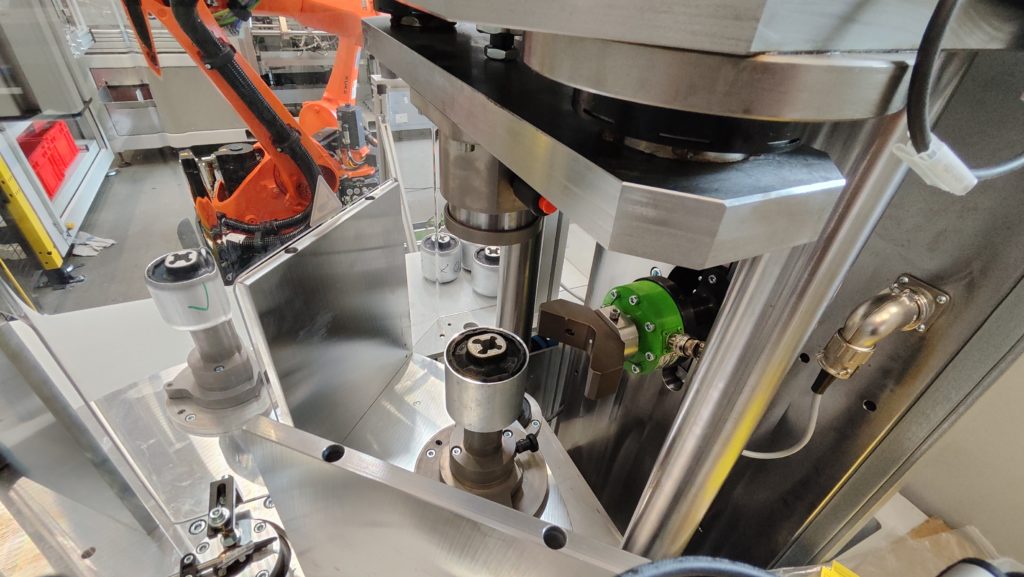

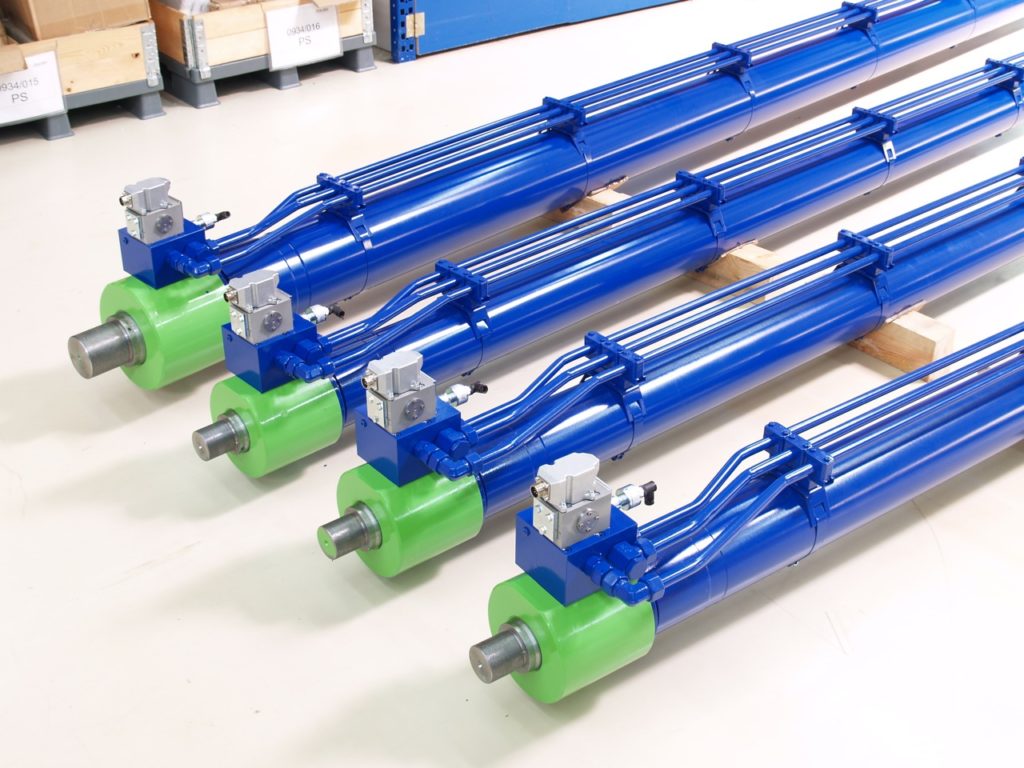

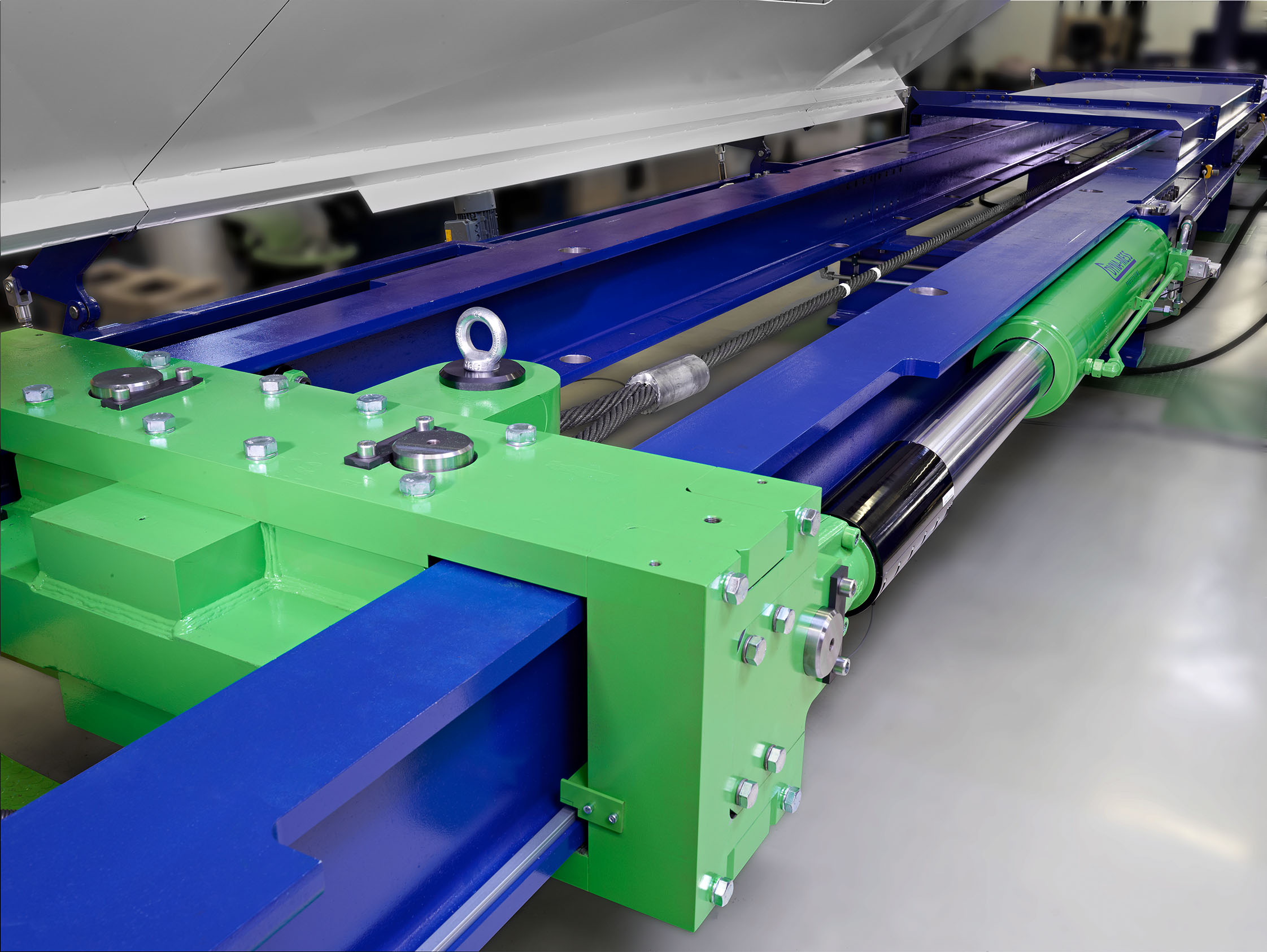

Application example: Screws up to M 72

Fasteners used in wind power technology, for example, place high demands on testing technology. Bolts with a size of up to M 72 can be loaded with forces in the meganewton range and pulled until they break. The testing software ensures that a tensile test is carried out in accordance with EN 6892, in which all parameters such as modulus of elasticity, tensile strength, yield strength, etc. are determined.

SUITABLE PRODUCTS

DYNA-RubberCrack

Electrodynamic testing machine for crack propagation tests according to ISO 27727, with which the fatigue crack growth of vulcanised rubber is measured.

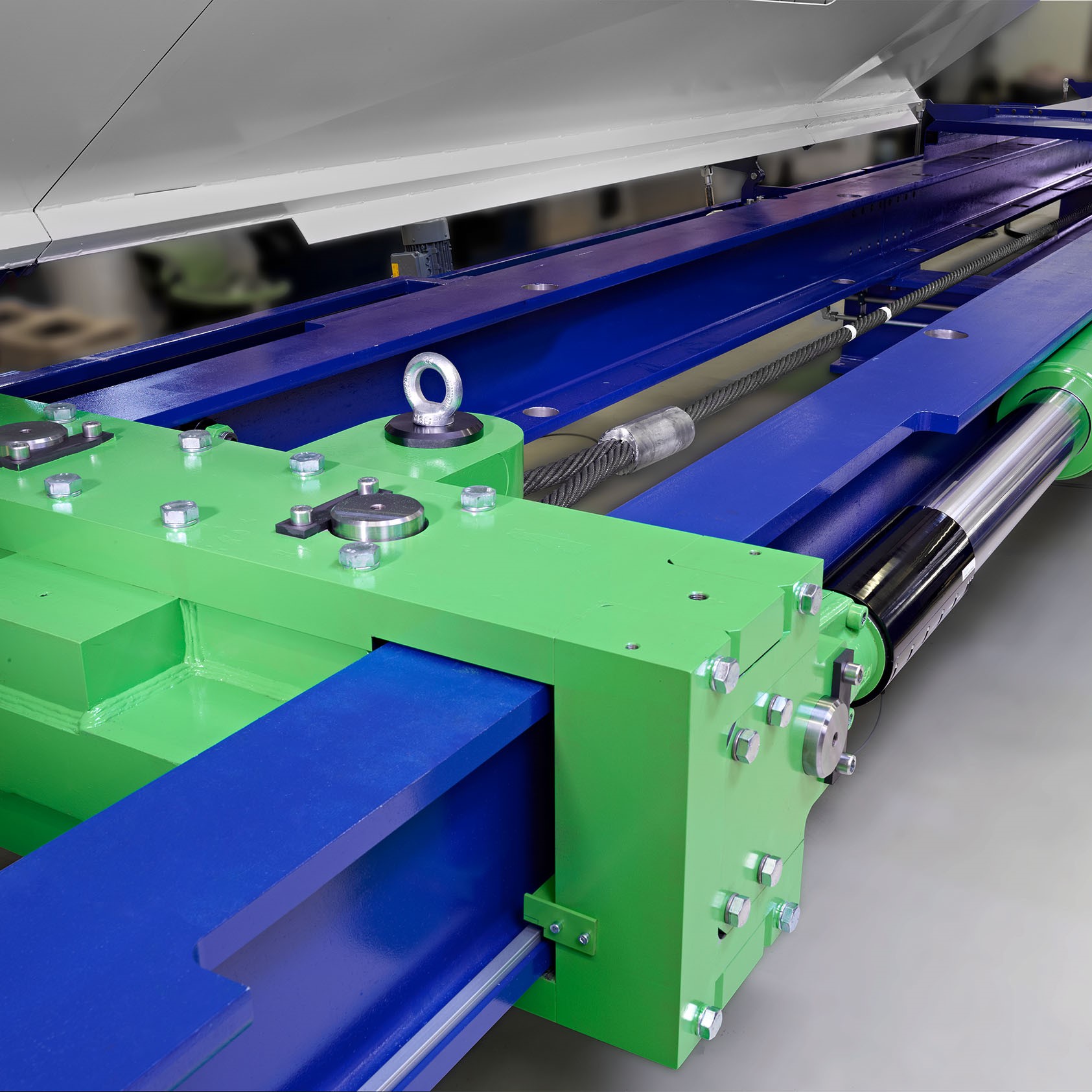

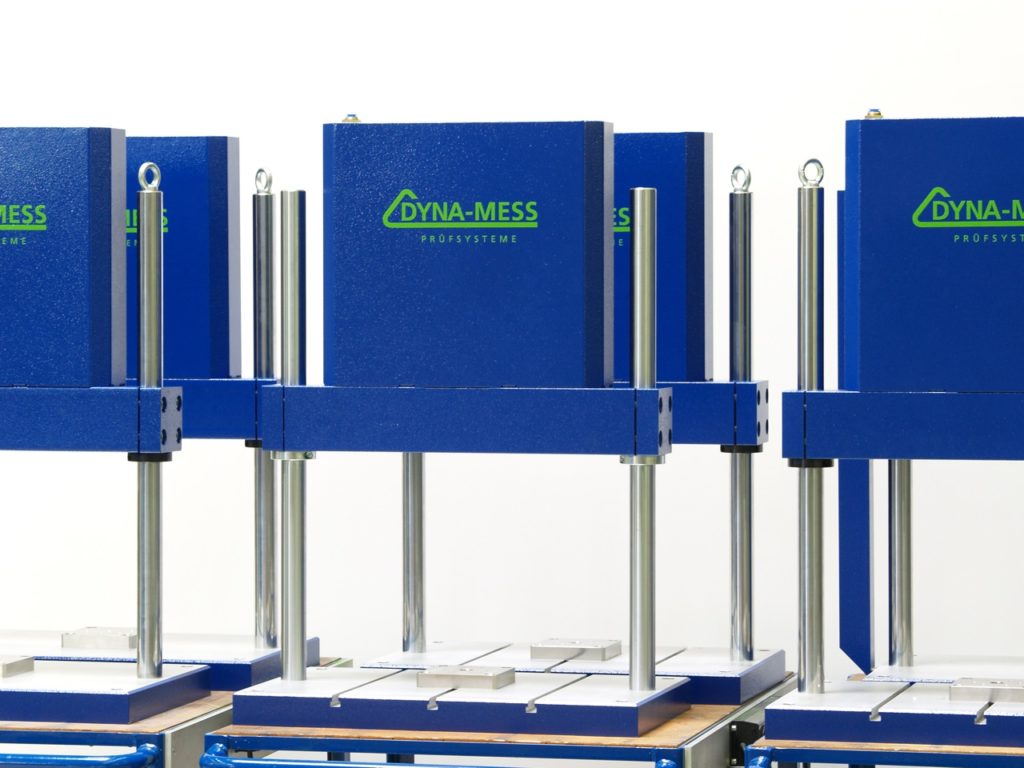

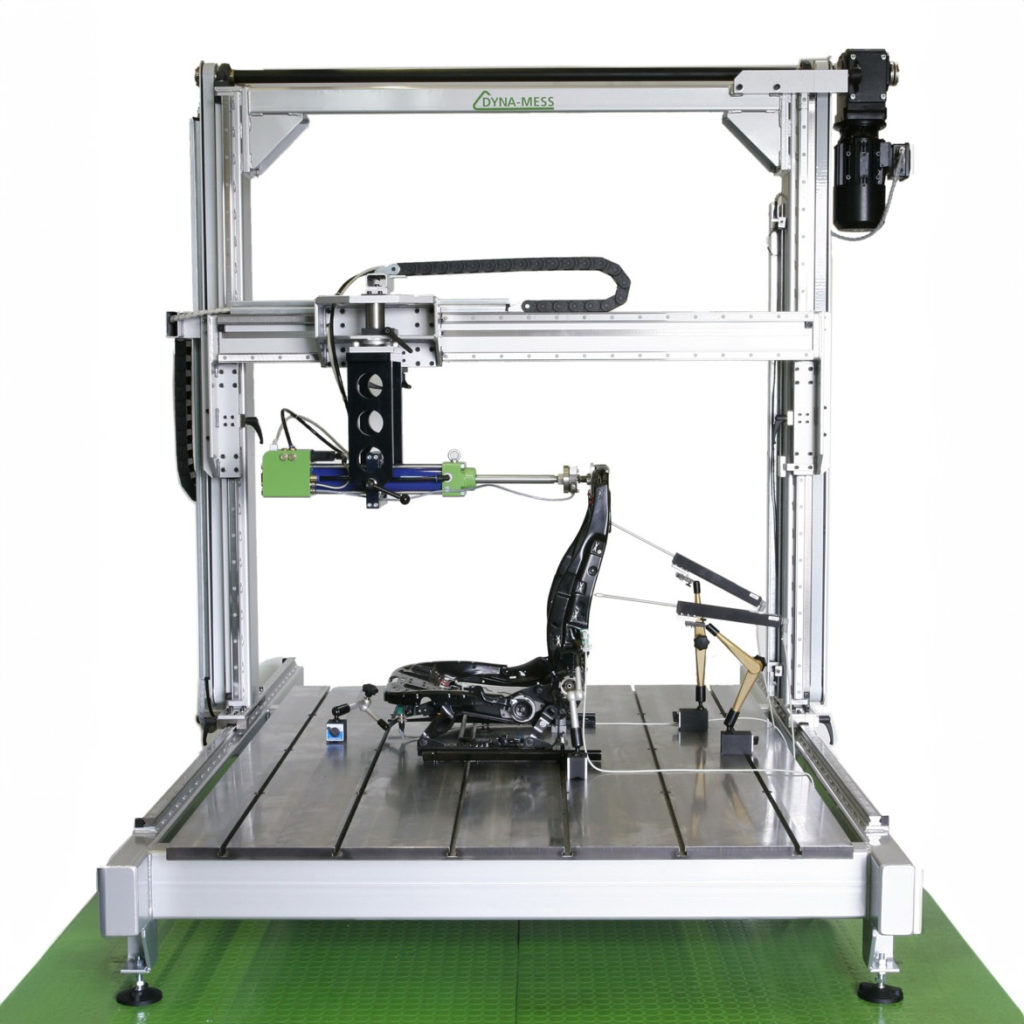

Horizontal testing machines

Horizontal testing machines from DYNA-MESS offer flexible testing options for various applications.

Standardised test solutions

DYNA-MESS serves many industries with various testing machines and also covers individual applications.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems