Steering wheel

Steering wheel

Vibration resistance tests are carried out on steering wheel skeletons as well as on complete steering wheels. In most cases, the steering wheels are fixed to the central hub and loaded on the steering wheel rim. Continuous actuation tests on horns and switches are usually carried out on the complete steering wheel.

We are DYNA-MESS. Test Systems.

Tests

Fatigue strength

During these tests, a dynamic load is applied to the steering wheel rim. The load direction can be

- axial or

- at an angle to the steering wheel plane or

- tangential

The test frequencies are 1 to 10 Hz and the loads are in the range < 1 kN. The steering wheels are loaded either until failure due to breakage or up to a target number of load cycles and then examined for visible damage, cracks or permanent deformation.

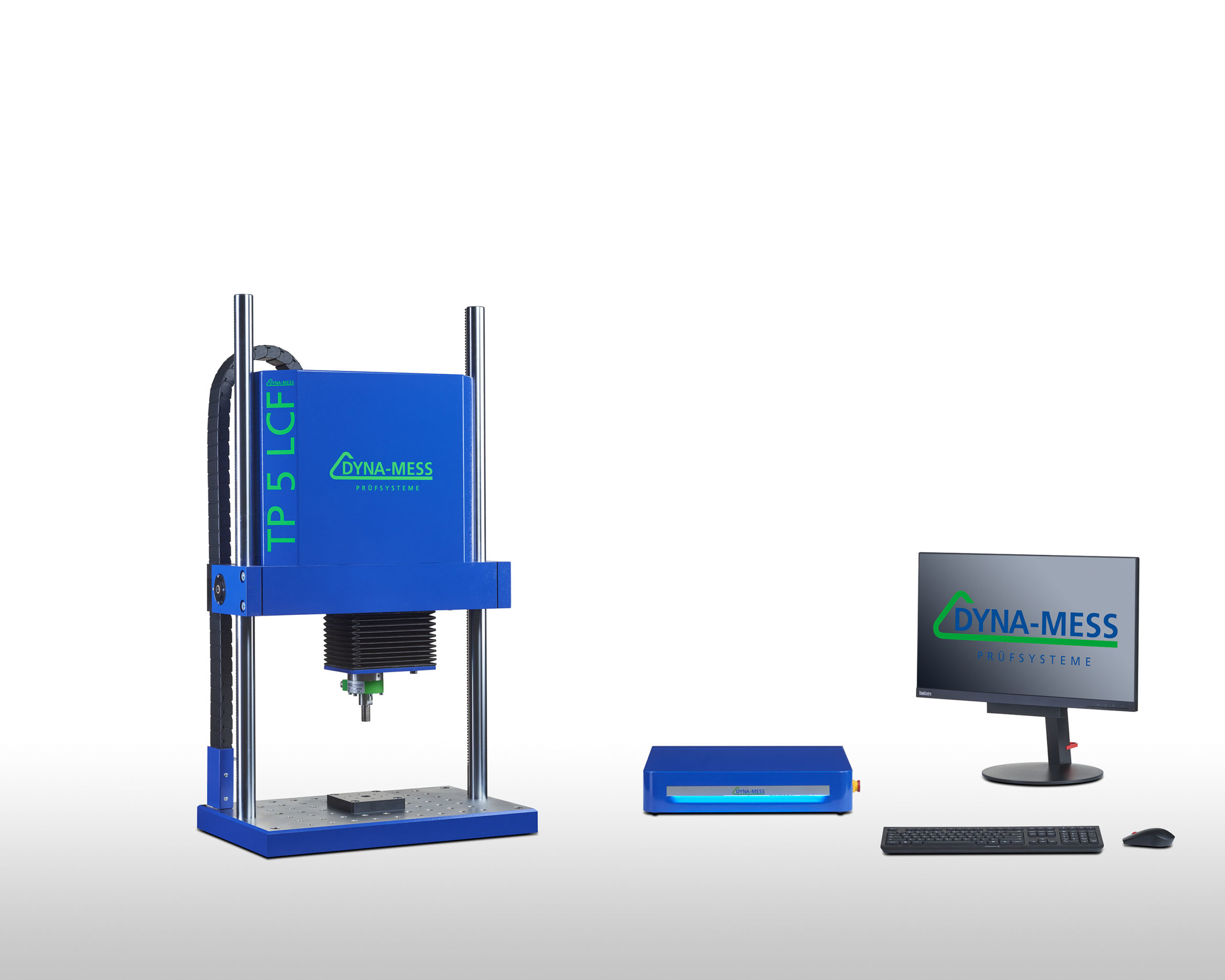

DYNA-MESS standard table-top testing machines or the DYNA-BAT can be used for these endurance tests.

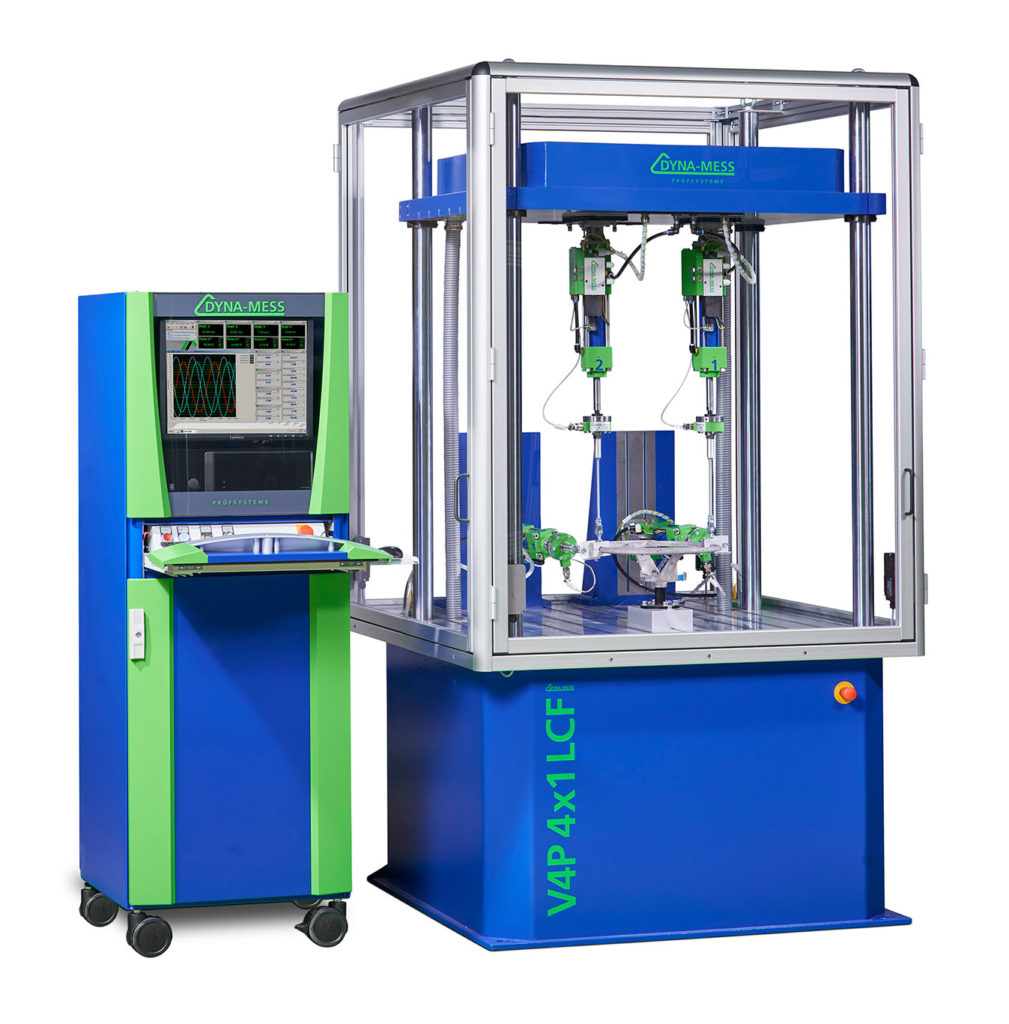

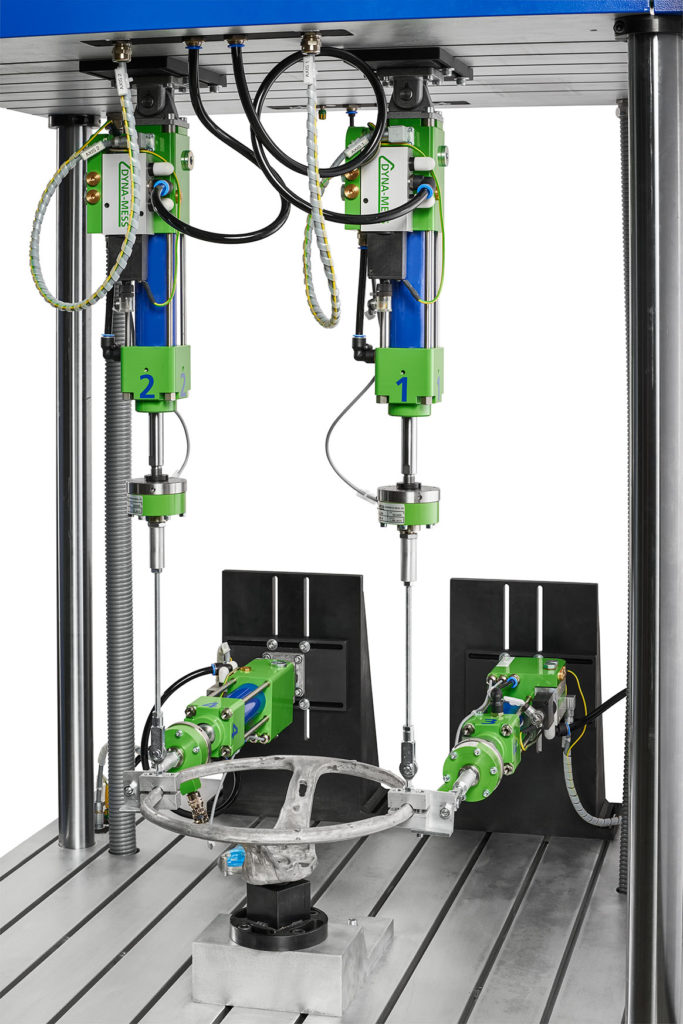

Multi-axis loads

Complex loads are realised with multi-axial test equipment. Torsion drives can be combined with linear drives or several linear cylinders can be used. For example, combined loads such as “torsion and simultaneous bending load” can be visualised.

The DYNA-MESS testing software not only ensures exact compliance with the peak load, but also guarantees an exact phase relationship between the individual loads.

Permanent deformation

One criterion in the assessment of steering wheels is the permanent deformation resulting from an applied load. This is determined by measuring the change in position of a measuring point on the steering wheel before and after the load.

These tests can also be carried out on DYNA-MESS machines. The testing software offers the option of measuring the change in position without dismantling the steering wheel. This means that the load and measurement of the permanent deformation take place in one machine and automated test sequences with determination of the permanent deformation as a function of the load can be carried out.

Torsion tests

In addition to tests in which linear drives are used, tests with torsion drives are also carried out on steering wheels.

The steering wheels are fixed to the rim and loaded by a central torsion drive on the hub. The loads can be applied both quasi-statically and dynamically in continuous oscillation mode.

The evaluation criteria are breakage, cracks, visible damage or permanent deformation.

Depending on the task, servo-electric, servo-pneumatic or servo-hydraulic DYNA-MESS torsion testing machines are used.

SUITABLE PRODUCTS

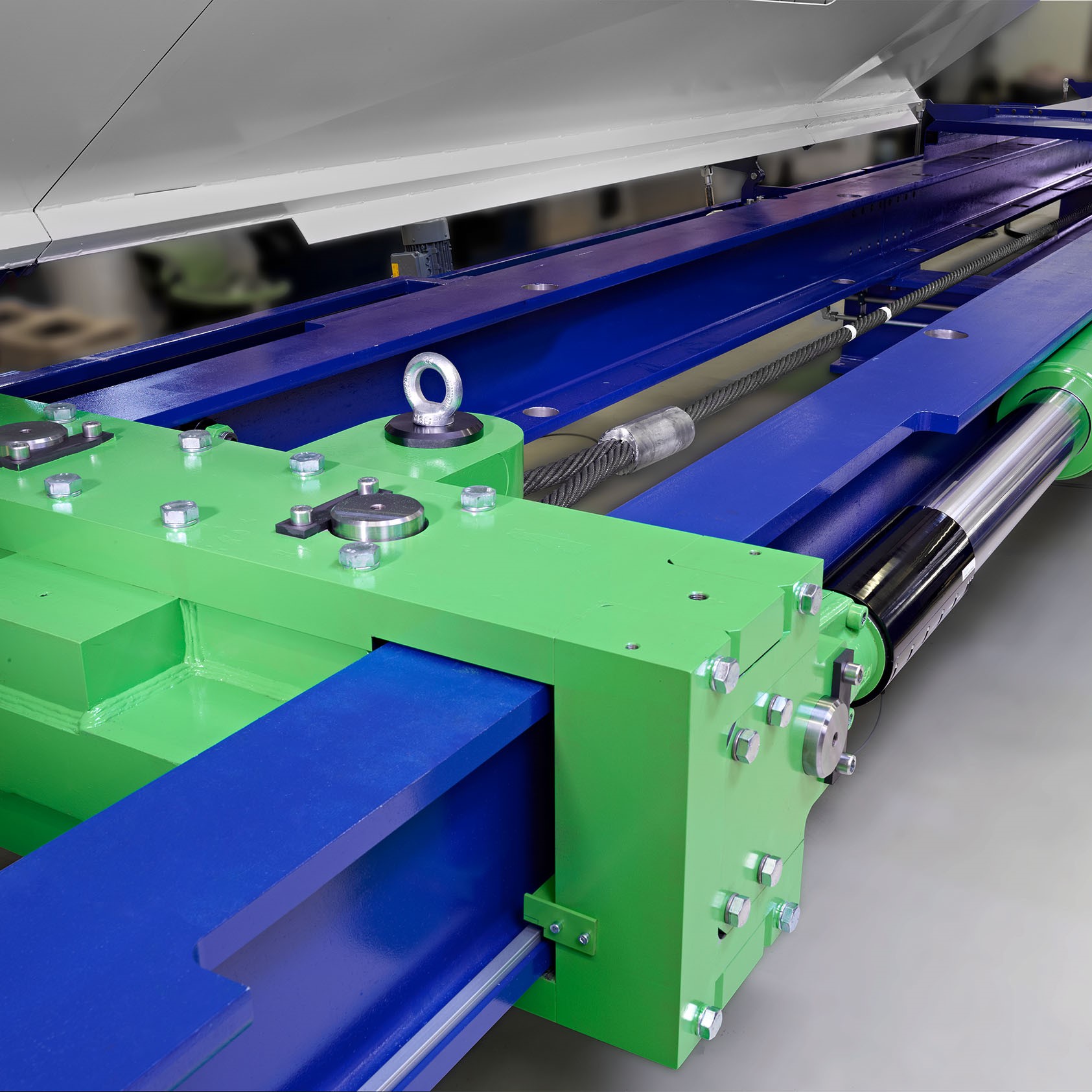

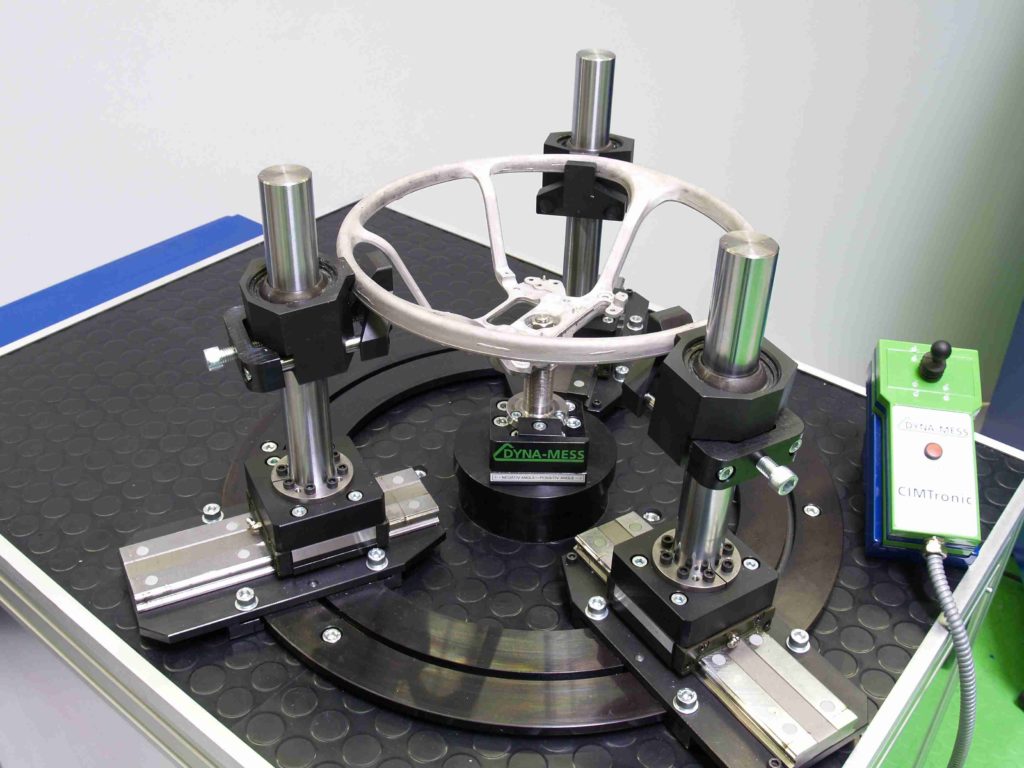

DYNA-BAT: Bi-axial tester

The DYNA-BAT steering wheel bi-axial tester is a test bench for car steering wheels.

DYNA-HAT + DYNA BDT

DYNA-HAT and DYNA-BDT are the ideal products for testing the horn push force and service life of switches on steering wheels.

OUR SERVICES FOR YOU

Calibration

Adjusting test systems

Precisely calibrated for reliable measurement results and quality assurance

Maintenance

Maintain test systems

Professional maintenance for optimum performance and a long service life

Repair

Repairing test systems

Repairs for smooth operation and optimum performance

Modernisation

Test systems always up to date

Modern technology for improved performance and accuracy

Accessories

Upgrade test systems

Advanced functions and technologies complete testing machines

Training

Understanding test systems

User and topic training on all aspects of DYNA-MESS test systems