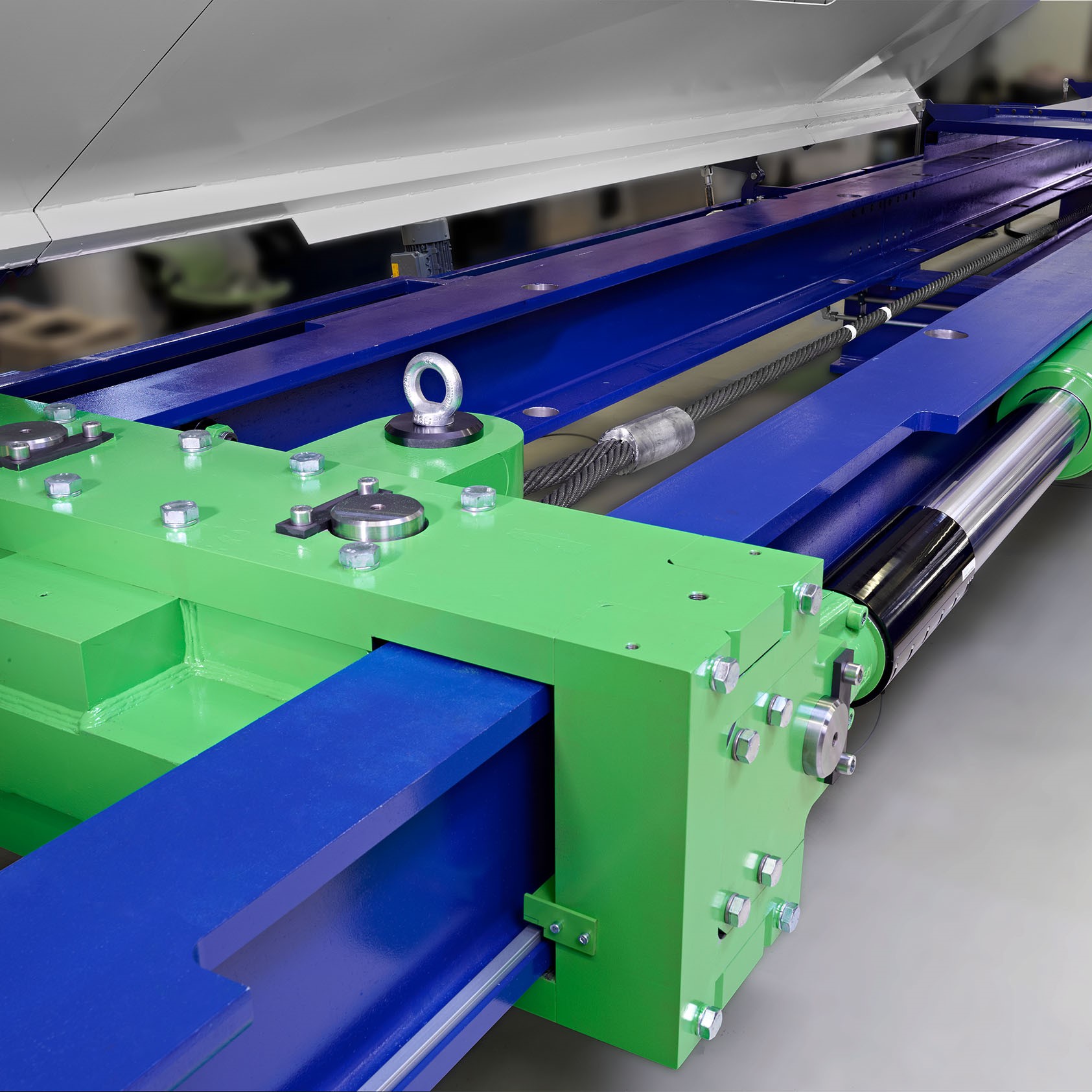

DYNA-BPS

DYNA-BPS: Brake Pedal System

Die Torsionsprüfmaschine DYNA-BPS wird für die dynamische Bauteilprüfung an elektrischen Bremspedalen eingesetzt.

Wir sind DYNA-MESS. Prüfsysteme.

Technische Eigenschaften

- Funktionsprüfung an elektrischen Bremspedalen

- Dauerlaufprüfung an elektrischen Bremspedalen

- Prüfung unter Klimabedingungen

- Temperaturbereich -40°C bis 180 °C

- Temperaturänderungsgeschwindigkeit 7 K/min

- Feuchtebereich 10-98 % r.F.

UNSERE SERVICES FÜR SIE

Kalibrierung

Prüfsysteme justieren

Präzise kalibriert für zuverlässige Messergebnisse und Qualitätssicherung

Wartung

Prüfsysteme pflegen

Professionelle Wartung für optimale Leistung und lange Lebensdauer

Reparatur

Prüfsysteme instandsetzen

Reparaturen für reibungslosen Betrieb und optimale Leistung

Modernisierung

Prüfsysteme immer aktuell

Moderne Technologie für verbesserte Leistung und Genauigkeit

Zubehör

Prüfsysteme aufrüsten

Erweiterte Funktionen und Technologien komplettieren Prüfmaschinen

Schulungen

Prüfsysteme verstehen

Anwender- und Themenschulungen rund um DYNA-MESS Prüfsysteme